Feeling lost in a sea of interview questions? Landed that dream interview for Concrete Stone Fabricator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Concrete Stone Fabricator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

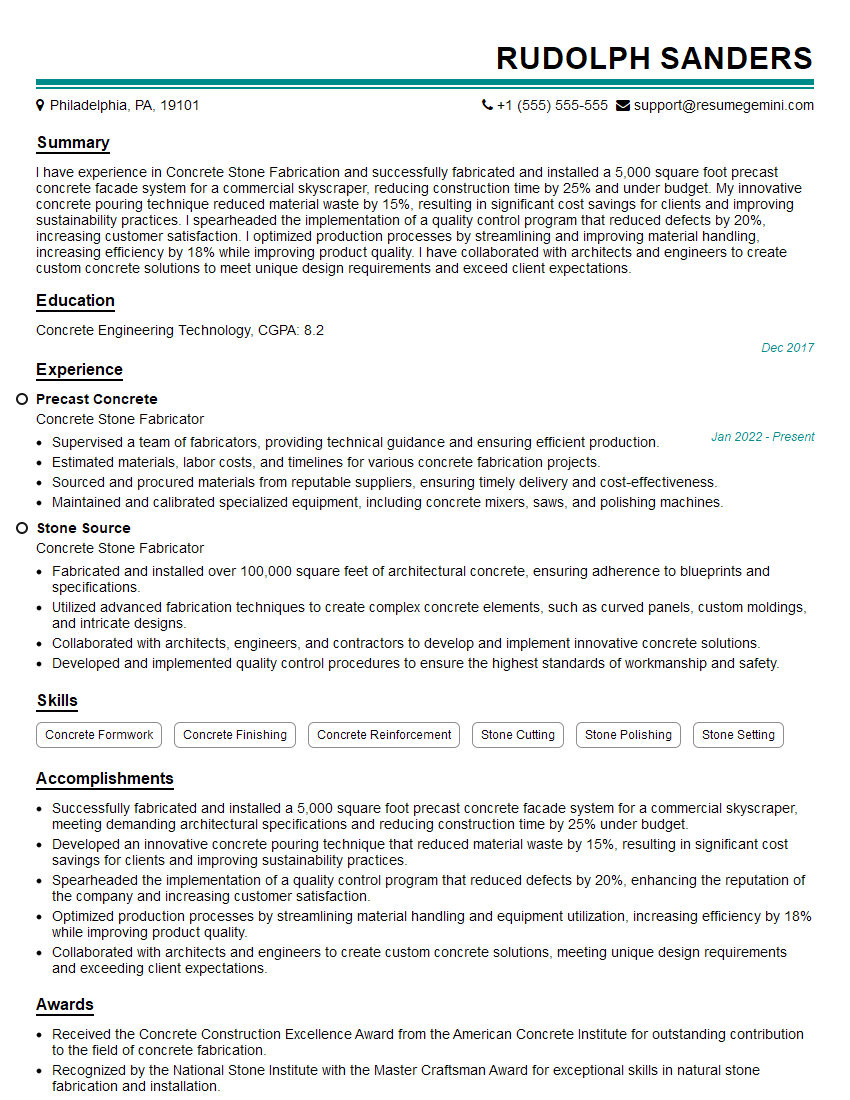

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Stone Fabricator

1. Explain the process of fabricating a concrete countertop?

The process of fabricating a concrete countertop involves several steps:

- Design and Planning: Determine the desired shape, size, color, and finish of the countertop.

- Mold Preparation: Create a mold using melamine or plywood to support the wet concrete.

- Concrete Mixing and Pouring: Mix concrete according to specifications, pour it into the mold, and vibrate to remove air bubbles.

- Curing: Allow the concrete to cure for several days to gain strength.

- Stripping and Sealing: Remove the mold, grind and polish the surface, and apply a sealant for protection.

2. Describe the different types of concrete mixes used in countertop fabrication?

- Standard Concrete Mix: A general-purpose mix suitable for most applications.

- High-Performance Concrete Mix: Contains admixtures to increase strength, durability, and resistance to wear.

- Lightweight Concrete Mix: Uses lightweight aggregates, such as pumice or expanded clay, to reduce weight.

- Fiber-Reinforced Concrete Mix: Incorporates fibers to enhance flexural strength and reduce cracking.

3. How do you ensure the accuracy and precision of your fabrication work?

To ensure accuracy and precision, I employ the following techniques:

- Laser Measurement and Layout: Use laser levels and measuring tools to ensure precise measurements and layout.

- Template Fabrication: Create accurate templates from the design to guide the cutting and fabrication process.

- CNC Machinery: Utilize computer-controlled machinery, such as CNC routers, for precise cutting and shaping.

- Quality Control Checks: Regularly inspect work at various stages to identify and correct any errors or deviations.

4. What are the common challenges faced in concrete countertop fabrication and how do you overcome them?

- Cracking: Use fiber reinforcement, control shrinkage, and proper curing to mitigate cracking.

- Color Variations: Carefully select and mix concrete components to ensure consistent color.

- Imperfections: Inspect raw materials, use high-quality molds, and employ skilled finishing techniques to minimize imperfections.

- Warping: Reinforce concrete with steel bars or fibers, cure it properly, and avoid rapid drying to prevent warping.

5. Explain the importance of proper curing in concrete countertop fabrication?

- Strength Development: Curing allows the concrete to gain strength gradually and develop its full potential.

- Reduced Cracking: Controlled curing prevents rapid drying, minimizing the risk of cracking.

- Improved Durability: Curing enhances the concrete’s resistance to moisture, wear, and chemicals.

- Enhanced Surface Finish: Proper curing provides an optimal surface for grinding and polishing, resulting in a better finish.

6. Describe the different finishing techniques used for concrete countertops?

- Grinding: Levels and smooths the concrete surface.

- Polishing: Creates a glossy, reflective finish.

- Honing: Produces a matte, satin-like finish.

- Staining: Enhances the color and appearance of the concrete.

- Acid Etching: Adds texture and exposes the aggregate.

7. How do you ensure that the countertops you fabricate meet industry standards and customer specifications?

- Compliance with Standards: Adhere to industry standards, such as ASTM C939 and ACI 318.

- Customer Communication: Collaborate with customers to understand their requirements and ensure satisfaction.

- Quality Control: Implement a comprehensive quality control system to monitor fabrication processes and identify potential issues.

- Feedback and Improvement: Regularly seek customer feedback and use it to enhance fabrication practices.

8. Describe your experience in working with different types of stone materials?

I have experience in working with various types of stone materials, including:

- Marble

- Granite

- Quartzite

- Sandstone

- Limestone

Each stone material has its unique characteristics, and I have developed specialized techniques to fabricate and finish them to the highest standards.

9. How do you stay updated with the latest trends and advancements in concrete countertop fabrication?

- Industry Publications: Subscribe to industry magazines and journals.

- Trade Shows and Conferences: Attend industry events to learn about new products and techniques.

- Online Resources: Explore online forums and websites dedicated to concrete countertops.

- Networking with Professionals: Connect with other fabricators and industry experts.

10. What sets you apart from other concrete countertop fabricators?

- Expertise and Experience: Years of experience and a deep understanding of concrete.

- Attention to Detail: Meticulous approach to ensure precision and quality.

- Customer Focus: Commitment to meeting customer requirements and delivering exceptional service.

- Innovation: Willingness to explore new techniques and incorporate advancements.

- Passion for Concrete: A genuine interest and passion for working with concrete.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Stone Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Stone Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Stone Fabricators cut, shape and finish stone products for use in construction projects. They may work with a variety of materials, including marble, granite, limestone and quartz. Their responsibilities typically include:

1. Cutting and shaping stone

Concrete Stone Fabricators use a variety of tools and equipment to cut and shape stone, including saws, grinders and polishers. They must be able to work accurately and precisely to create the desired shapes and dimensions.

- Reading and understanding blueprints and drawings

- Operating saws, grinders, and other equipment

2. Finishing stone surfaces

Concrete Stone Fabricators finish stone surfaces using a variety of techniques, including polishing, honing and sandblasting. They must be able to create a variety of finishes, from smooth and glossy to rough and textured.

- Polishing and honing stone surfaces

- Sandblasting and texturing stone surfaces

3. Installing stone products

Concrete Stone Fabricators may also be responsible for installing stone products, such as countertops, tiles and flooring. They must be able to work safely and efficiently to ensure that the products are installed correctly and to the customer’s satisfaction.

- Installing countertops, tiles and flooring

- Grouting and sealing stone products

4. Maintaining equipment

Concrete Stone Fabricators are responsible for maintaining their equipment in good working condition. They must be able to troubleshoot problems and make minor repairs as needed.

- Cleaning and lubricating equipment

- Replacing worn parts

Interview Tips

To ace the interview for a Concrete Stone Fabricator position, it is important to:

1. Research the company and the position

Take some time to learn about the company you are applying to and the specific position you are interested in. This will help you to answer questions intelligently and show that you are genuinely interested in the opportunity.

- Visit the company’s website

- Read industry news and articles

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to answer questions

- Quantify your accomplishments whenever possible

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Concrete Stone Fabricator. Be prepared to discuss your qualifications in detail, including your experience with different types of stone, your skills in cutting and shaping stone, and your knowledge of stone installation techniques.

- Highlight your most relevant experience and skills

- Be prepared to provide examples of your work

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are taking the interview seriously. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture

- Ask about the training and development opportunities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Stone Fabricator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.