Are you gearing up for an interview for a Concrete Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Concrete Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

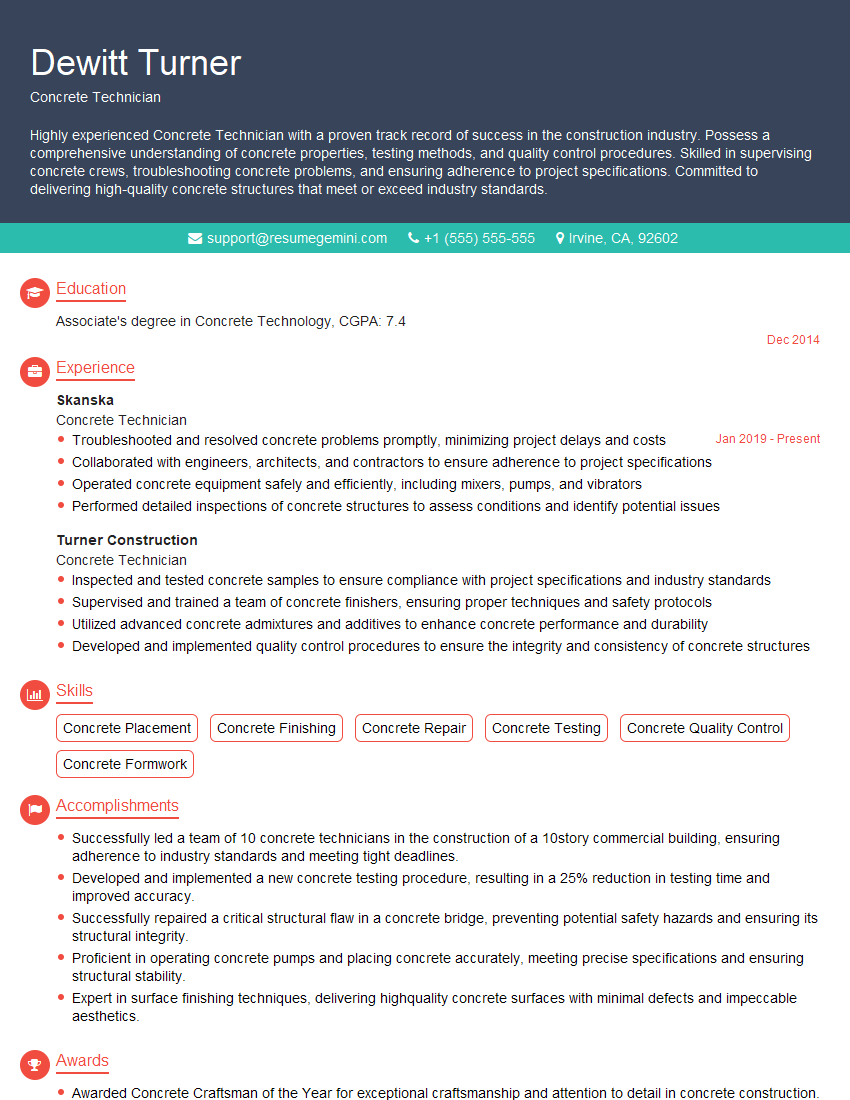

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Technician

1. Describe the process of concrete finishing, including the different techniques and equipment used?

The process of concrete finishing involves several steps to achieve a smooth, durable, and aesthetically pleasing surface.

- Floating: Leveling and smoothing the concrete surface using a bull float or power trowel.

- Troweling: Further smoothing and compacting the surface with a hand trowel or power trowel to create a dense and wear-resistant finish.

- Jointing: Creating joints or control cuts in the concrete to prevent cracking and allow for movement.

- Curing: Maintaining moisture in the concrete to allow for proper hydration and strength development.

- Sealing: Applying a protective coating to the concrete surface to enhance durability, resistance to stains, and moisture penetration.

2. Explain the importance of proper concrete mix design and how it affects the finished product?

Quality of Ingredients:

- The quality of cement, aggregates (sand, gravel), and water directly influences the strength, durability, and performance of the concrete.

- Proper proportions and grading of these materials ensure optimal workability, setting time, and long-term performance.

Mix Ratios:

- The mix design determines the ratios of cement, aggregates, and water, which affects the concrete’s strength, workability, and cost.

- Adjustments to these ratios can be made to achieve specific properties for different applications.

Additives:

- Chemical admixtures can be added to the mix design to modify properties such as setting time, strength, workability, and durability.

- Proper selection and use of additives can enhance concrete’s performance and meet specific project requirements.

3. Discuss the different types of concrete admixtures and their uses?

- Set Accelerators: Reduce setting time, allowing for faster finishing and earlier strength development.

- Set Retarders: Delay setting time, providing more time for finishing operations or placement in hot weather.

- Air-Entraining Agents: Introduce tiny air bubbles into the concrete, improving workability, freeze-thaw resistance, and durability.

- Superplasticizers: Reduce the water content required for a given workability, resulting in higher strength and durability.

- Water-Reducing Agents: Lower the water content without affecting workability, resulting in increased strength and reduced shrinkage.

4. Describe the testing procedures used to ensure the quality of concrete, and explain how you interpret the results?

- Slump Test: Measures the workability of fresh concrete by determining how much it slumps or flows under its own weight.

- Compressive Strength Test: Evaluates the concrete’s ability to withstand compressive forces, providing an indication of its overall strength.

- Air Content Test: Determines the percentage of air bubbles in the concrete, which affects its durability and resistance to freezing and thawing.

- Chloride Ion Permeability Test: Measures the resistance of concrete to chloride ion penetration, which can cause corrosion of steel reinforcement.

Interpreting Results:

- Comparing test results to industry standards and project specifications to assess conformance.

- Identifying deviations from specifications and recommending corrective actions or modifications to the mix design.

5. What are the common causes of concrete defects and how can they be prevented?

Causes:

- Improper mix design or proportions.

- Inadequate curing or improper finishing techniques.

- Exposure to excessive heat or cold during placement.

- Bleeding or segregation of concrete components.

- Chemical reactions or contaminants in the concrete mix.

Prevention:

- Ensuring proper mix design and quality control.

- Following recommended placement and finishing procedures.

- Providing adequate curing conditions and protecting concrete from extreme temperatures.

- Using admixtures to mitigate bleeding or segregation.

- Testing concrete materials for potential contaminants.

6. Describe the different types of concrete reinforcement and their applications?

Types:

- Steel Reinforcement: Bars, wires, or meshes made of steel, used to improve tensile strength and prevent cracking.

- Fiber Reinforcement: Fibers added to the concrete mix, such as steel, glass, or polypropylene, to enhance toughness and reduce cracking.

- Structural Concrete: Designed to carry heavy loads, typically reinforced with steel bars or cages.

Applications:

- Foundations: To resist compressive and tensile forces, reinforced with steel bars or mesh.

- Beams and Columns: To carry and transfer loads, reinforced with steel bars or cages.

- Slabs: To provide flat surfaces, reinforced with steel mesh or fibers.

- Precast Concrete: Used in various applications, reinforced with steel or fibers for strength and durability.

7. What are the safety precautions that must be followed when working with concrete?

- Wearing appropriate protective gear, including gloves, safety glasses, and respirators.

- Avoiding contact with fresh concrete, as it can cause skin irritation and burns.

- Preventing inhalation of concrete dust, as it can lead to respiratory problems.

- Using caution when handling heavy equipment and materials.

- Following proper lifting techniques to avoid injuries.

- Being aware of potential hazards and taking measures to mitigate risks.

8. How do you ensure the accuracy and precision of concrete measurements and calculations?

- Using calibrated measuring devices, such as rulers, tapes, and scales.

- Double-checking measurements and calculations to minimize errors.

- Understanding the significance of measurement accuracy and precision for concrete work.

- Following established procedures and industry standards for measurements and calculations.

9. Describe the environmental regulations that apply to concrete construction and how you comply with them?

- Understanding local and regional environmental regulations related to concrete work.

- Complying with regulations on dust control, noise pollution, and waste management.

- Using environmentally friendly concrete materials and practices.

10. How do you stay updated with the latest advancements and technologies in the concrete industry?

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Participating in online forums and discussion groups.

- Seeking opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Technicians are responsible for the proper installation and maintenance of concrete structures. They work closely with engineers and architects to ensure that the concrete meets the required specifications and standards.

1. Concrete Placement

Concrete Technicians are responsible for placing concrete into forms or molds. They must ensure that the concrete is placed evenly and compacted properly to prevent voids or weak spots.

- Operate concrete mixers and pumps

- Pour concrete into forms and molds

- Level and smooth concrete surfaces

2. Concrete Finishing

Concrete Technicians are responsible for finishing concrete surfaces to the desired texture and smoothness. They may use a variety of tools and techniques to achieve the desired finish.

- Apply sealants and coatings to concrete surfaces

- Repair and patch damaged concrete

- Inspect concrete surfaces for defects

3. Concrete Testing

Concrete Technicians are responsible for testing concrete to ensure that it meets the required strength and durability standards. They may use a variety of testing methods to evaluate the concrete’s properties.

- Conduct tests on concrete samples

- Interpret test results and make recommendations

- Monitor the performance of concrete structures

4. Concrete Safety

Concrete Technicians must be aware of the potential hazards associated with working with concrete. They must follow all safety procedures and wear the appropriate protective gear.

- Follow all safety regulations and procedures

- Wear appropriate protective gear

- Be aware of the potential hazards of working with concrete

Interview Tips

Preparing for a Concrete Technician interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you understand their business, culture, and values. You can find information about the company on their website, social media pages, and news articles.

- Visit the company’s website

- Follow the company on social media

- Read news articles about the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Prepare answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience working with concrete. Be prepared to talk about your skills and knowledge in detail. You can also highlight any projects or accomplishments that you are particularly proud of.

- Highlight your skills and experience in concrete

- Discuss any projects or accomplishments that you are proud of

- Quantify your results whenever possible

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Wear clean, pressed clothes

- Dress in a way that is appropriate for the business setting

- Make sure your clothes are comfortable so that you can focus on the interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!