Are you gearing up for a career in Concreting Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Concreting Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

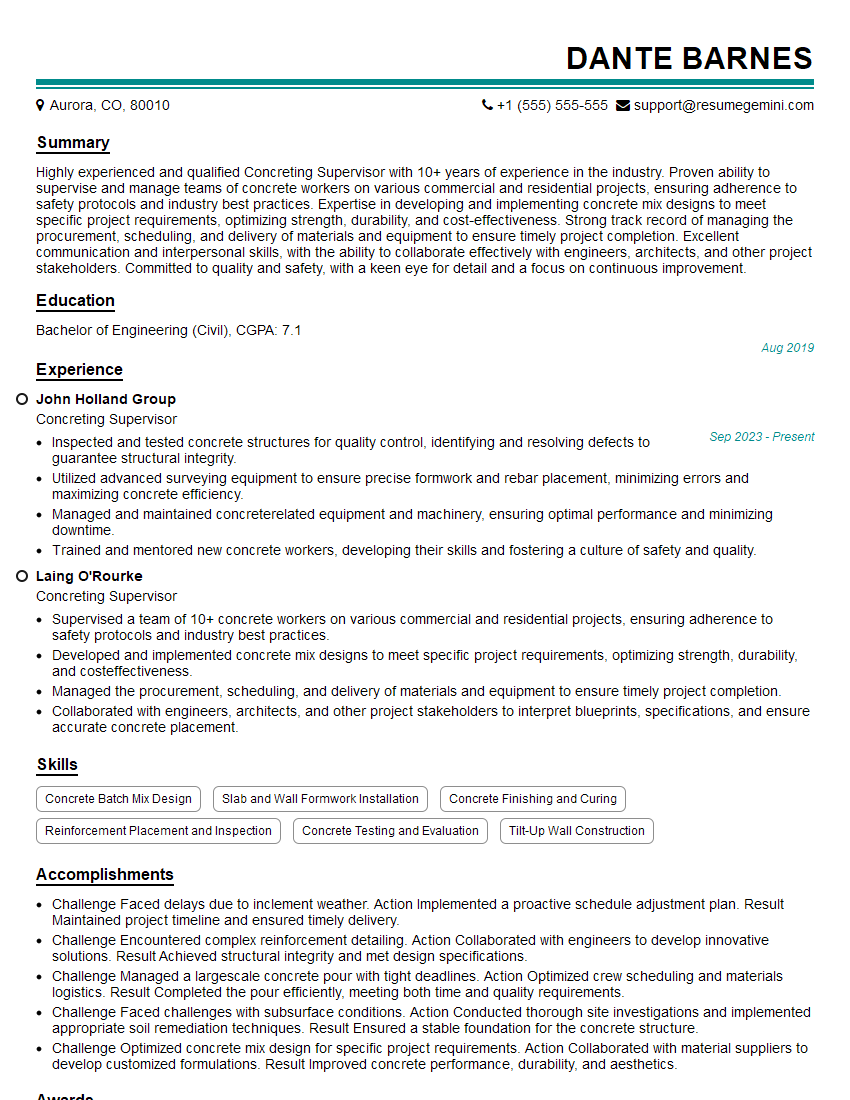

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concreting Supervisor

1. What are the different types of concrete mix designs and their applications?

There are various concrete mix designs, each tailored for specific applications. Here are a few common types:

- Normal Concrete Mix: General-purpose mix used for foundations, slabs, and other structural elements.

- High-Strength Concrete Mix: Designed for demanding applications requiring superior strength, such as bridges, skyscrapers, and columns.

- Fiber-Reinforced Concrete Mix: Incorporates fibers, such as steel or glass, to enhance tensile strength and durability.

- Self-Compacting Concrete Mix: Flows easily, eliminating the need for vibration, making it suitable for complex shapes and congested reinforcement.

- Lightweight Concrete Mix: Contains lightweight aggregates, reducing density while maintaining strength, ideal for high-rise buildings and seismic zones.

2. Describe the process of concrete curing and its importance for achieving desired properties.

Concrete Curing Process

- Initial Curing: Begins after concrete placement, preventing moisture loss and ensuring proper hydration.

- Moist Curing: Saturation of concrete with water or covering it with curing compounds to maintain moisture.

- Thermal Curing: Application of heat to accelerate hydration and enhance strength.

Importance of Curing

- Improves strength and durability

- Reduces cracking and shrinkage

- Enhances resistance to abrasion and weathering

- Optimizes bond between concrete and reinforcement

3. What are the methods for testing the strength of concrete and their applications?

Concrete strength testing methods include:

- Cylinder Compression Test: Widely used method, where cylindrical concrete samples are crushed to determine compressive strength.

- Cube Compression Test: Similar to cylinder test, but uses cubic samples, common in some regions.

- Beam Flexural Test: Tests the concrete’s ability to resist bending forces, important for structural elements like beams and slabs.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing and rebound hammer test provide non-invasive ways to assess concrete strength on site.

4. Explain the procedures for placing and finishing concrete for different applications.

Concrete placement and finishing vary depending on the application:

- Slab on Grade: Leveling the subgrade, placing concrete, and finishing it with power trowels or hand floats.

- Structural Concrete: Using formwork to shape concrete, ensuring proper placement and consolidation around reinforcement.

- Pavement Concrete: Placing concrete on a prepared subbase, using heavy equipment for compaction and finishing with specialized machines.

- Architectural Concrete: Placing and finishing concrete with high attention to aesthetics, using specialized techniques for exposed surfaces.

5. How do you ensure the quality of concrete construction and identify potential problems before they occur?

Quality control in concrete construction involves:

- Material Inspection: Verifying the quality of concrete ingredients, including cement, aggregates, and admixtures.

- Mix Design Review: Checking the mix design for compliance with specifications and suitability for the intended application.

- Testing and Monitoring: Conducting strength tests, slump tests, and other quality checks during concrete production and placement.

- Inspection of Workmanship: Ensuring proper placement, finishing, and curing techniques are followed.

- Problem Identification: Identifying potential issues early on, such as cold joints, segregation, or excessive shrinkage, and taking corrective measures.

6. What safety measures should be implemented during concrete construction?

- Personal Protective Equipment (PPE): Hard hats, safety glasses, gloves, and appropriate clothing.

- Fall Protection: Guardrails, safety harnesses, and designated work platforms.

- Respirator Use: Protection from dust and fumes when working with certain concrete materials.

- Handling and Storage of Chemicals: Proper storage, handling, and disposal of admixtures and other chemicals.

- Electrical Safety: Precautions against electrical hazards, including GFCI protection and grounding.

7. How do you manage a team of concrete workers and maintain productivity?

- Effective Communication: Clear communication of work instructions, safety protocols, and expectations.

- Team Coordination: Organizing schedules, assigning tasks, and ensuring smooth collaboration among workers.

- Training and Development: Providing necessary training to enhance skills and promote efficiency.

- Performance Monitoring: Tracking progress, identifying areas for improvement, and providing feedback.

- Recognition and Incentives: Acknowledging and rewarding good work to maintain motivation and productivity.

8. What is your approach to resolving conflicts or disputes on a construction site?

- Open Communication: Encouraging open dialogue and active listening to understand different perspectives.

- Collaboration: Facilitating discussions to find mutually acceptable solutions.

- Objective Analysis: Reviewing facts and perspectives objectively to identify root causes.

- Mediation or Negotiation: Involving a neutral third party to help resolve conflicts and reach agreements.

- Documentation: Clearly documenting resolutions and action plans to prevent future misunderstandings.

9. How do you stay updated with the latest advancements and best practices in concrete construction?

- Industry Publications and Journals: Reading trade magazines and journals to stay informed about new technologies, materials, and techniques.

- Conferences and Seminars: Attending industry events to learn from experts, network with peers, and discover innovative solutions.

- Online Resources: Utilizing online platforms, webinars, and certification programs to enhance knowledge and skills.

- Collaboration and Networking: Engaging with colleagues, industry professionals, and research institutions to share and exchange information.

- Continuing Education: Pursuing additional certifications and training to stay current with industry standards and best practices.

10. What sets you apart from other candidates for this role?

- Technical Expertise: Demonstrated proficiency in concrete mix design, testing, placement, and finishing techniques.

- Quality Orientation: Strong commitment to ensuring the highest quality standards in concrete construction.

- Project Management Skills: Experience in managing concrete construction projects, including scheduling, coordination, and safety.

- Leadership Abilities: Proven ability to lead and motivate teams, foster collaboration, and resolve conflicts.

- Growth Mindset: Passion for continuous learning, staying updated with industry advancements, and seeking opportunities for professional development.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concreting Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concreting Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Supervising all aspects of concrete construction, including planning, coordination, and execution, is the primary responsibility of a Concreting Supervisor. They ensure the project is completed on time, within budget, and meets all quality standards.

1. Planning and Coordination

A Concreting Supervisor’s planning and coordination responsibilities include:

- Developing and implementing concrete placement plans

- Coordinating with other project stakeholders, such as engineers, architects, and contractors

- Scheduling and managing concrete deliveries

- Ensuring that the worksite is prepared for concrete placement

2. Execution and Inspection

During concrete placement, a Concreting Supervisor oversees the following:

- Inspecting concrete before, during, and after placement

- Monitoring concrete curing conditions

- Troubleshooting any problems that may arise during concrete placement

- Ensuring that all safety regulations are followed

3. Quality Control

A Concreting Supervisor is responsible for ensuring that the concrete meets all quality standards. This includes:

- Testing concrete samples

- Inspecting finished concrete surfaces

- Maintaining records of all quality control tests and inspections

4. Communication and Reporting

Effective communication and reporting are essential for a Concreting Supervisor. They must be able to:

- Communicate effectively with all project stakeholders

- Prepare and submit reports on concrete placement and quality

- Document all project-related activities

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are a few tips to help you ace your Concreting Supervisor interview:

1. Research the Company and Position

Before the interview, take the time to learn as much as you can about the company and the specific role you’re applying for. This will help you understand the company’s culture, values, and goals, and it will also give you a better idea of what the interviewer is looking for in a candidate.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in Concreting Supervisor interviews, such as:

- Tell me about your experience in concrete construction.

- What are your strengths and weaknesses as a Concreting Supervisor?

- How do you ensure that the concrete meets all quality standards?

- How do you handle challenges that may arise during concrete placement?

Take some time to practice answering these and other common interview questions, so that you can deliver confident and well-prepared responses on the day of your interview.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are most relevant to the job. For example, if you have experience in planning and coordinating large concrete placement projects, be sure to mention that in your interview. You should also emphasize your knowledge of concrete construction standards and your commitment to safety.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the company’s goals for this project?

- What are the biggest challenges that the company is facing in this industry?

- What opportunities are there for professional development within the company?

5. Be Professional and Enthusiastic

Throughout the interview, it’s important to be professional, courteous, and enthusiastic. Make eye contact with the interviewer, answer questions clearly and concisely, and show that you’re genuinely interested in the position. Your enthusiasm and professionalism will make a positive impression on the interviewer and increase your chances of getting the job.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concreting Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!