Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Conditioner Tumbler Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

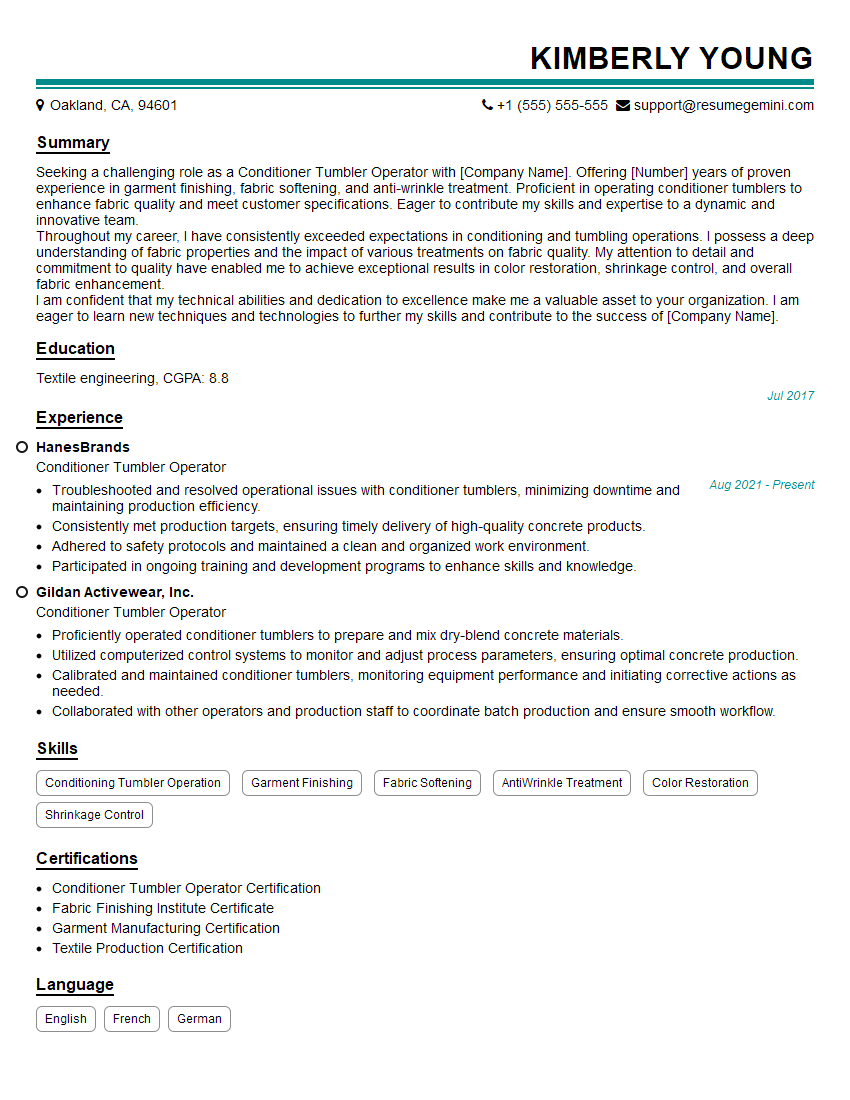

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conditioner Tumbler Operator

1. What are the key responsibilities of a Conditioner Tumbler Operator?

The key responsibilities of a Conditioner Tumbler Operator include:

- Operating conditioner tumblers to prepare chemicals, materials, and products

- Monitoring the operation of conditioner tumblers and making adjustments as needed

- Maintaining the conditioner tumblers and ensuring they are in good working order

- Following safety protocols and procedures

- Working with other team members to ensure the smooth operation of the production process

2. What are the different types of conditioner tumblers?

Rotary Tumblers

- Used for gentle mixing and tumbling of materials

- Effective for blending solids with liquids or powders

Vibratory Tumblers

- Employ a vibrating motion to mix and polish materials

- Suitable for delicate or abrasive materials

3. What are the factors to consider when selecting a conditioner tumbler?

When selecting a conditioner tumbler, the following factors should be considered:

- Capacity and size of the tumbler

- Type of materials to be processed

- Desired mixing action

- Speed and duration of mixing

- Maintenance and cleaning requirements

4. How do you maintain the conditioner tumblers?

Maintaining conditioner tumblers involves the following steps:

- Regular cleaning to remove any residue or build-up

- Periodic lubrication of moving parts

- Checking and tightening bolts and screws

- Inspecting electrical components for any damage or wear

- Calibrating the tumbler to ensure accuracy and efficiency

5. What safety precautions should be taken when operating conditioner tumblers?

When operating conditioner tumblers, it is essential to adhere to the following safety precautions:

- Always wear appropriate personal protective equipment (PPE)

- Ensure the tumbler is properly grounded and electrically safe

- Never operate the tumbler with the lid open

- Avoid overloading the tumbler

- Follow lockout/tagout procedures when performing maintenance or repairs

6. What are the common problems that can occur with conditioner tumblers?

Common problems that can occur with conditioner tumblers include:

- Mechanical failures, such as bearing or motor problems

- Electrical issues, such as wiring faults or control panel malfunctions

- Improper mixing or tumbling due to incorrect settings or worn components

- Overheating due to excessive load or inadequate ventilation

7. How do you troubleshoot and resolve problems with conditioner tumblers?

To troubleshoot and resolve problems with conditioner tumblers:

- Identify the problem by observing symptoms and checking for error messages

- Consult the manufacturer’s manual or technical documentation for guidance

- Perform basic troubleshooting steps, such as restarting the tumbler or checking connections

- If the problem persists, contact a qualified technician or the manufacturer for assistance

8. What are the quality control procedures for conditioner tumblers?

Quality control procedures for conditioner tumblers involve:

- Regular calibration and verification of the tumbler’s performance

- Monitoring the mixing process and product quality

- Maintaining records of maintenance and repairs

- Implementing corrective actions to address any deviations or non-conformities

9. How do you ensure the safety and efficiency of conditioner tumblers?

To ensure the safety and efficiency of conditioner tumblers:

- Follow proper operating procedures and safety guidelines

- Perform regular inspections and maintenance to identify and address potential issues

- Use appropriate personal protective equipment (PPE) and follow lockout/tagout procedures

- Monitor the tumbler’s performance and adjust settings as needed to optimize mixing and product quality

10. What is your experience with different types of conditioner tumblers?

I have experience operating and maintaining various types of conditioner tumblers, including:

- Rotary tumblers for gentle mixing of powders and liquids

- Vibratory tumblers for polishing and deburring of metal parts

- Continuous tumblers for high-volume mixing and processing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conditioner Tumbler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conditioner Tumbler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities The role of the Conditioner Tumbler Operator is crucial in ensuring the efficient and effective conditioning and tumbling processes of textiles within a manufacturing facility. Here are the key job responsibilities of a Conditioner Tumbler Operator: ### 1. Conditioning and Tumbling Textiles – Operate and monitor conditioner tumblers to evenly distribute chemicals and softeners throughout textile fabrics – Adjust machine settings, including temperature, moisture, and tumbling action, to optimize conditioning and tumbling processes – Ensure textiles are properly loaded, unloaded, and handled throughout the process ### 2. Maintain Equipment – Conduct regular inspections and maintenance of conditioner tumblers and related equipment to ensure proper functioning – Identify and troubleshoot any issues or malfunctions, and make necessary repairs or request assistance as needed – Maintain a clean and organized work area to minimize workplace hazards ### 3. Monitor and Control Processes – Monitor temperature, moisture, and other process parameters to ensure compliance with established standards – Take corrective actions to adjust processes and maintain optimal conditions for textile treatment – Record process data and maintain production logs to track and optimize efficiency ### 4. Safety and Compliance – Comply with all safety regulations and procedures to ensure a safe working environment – Wear appropriate personal protective equipment (PPE) at all times – Handle chemicals and other hazardous materials safely and responsibly ## Interview Preparation Tips To help candidates ace the interview for a Conditioner Tumbler Operator position, here are some essential preparation tips: ### 1. Research the Company and Industry – Familiarize yourself with the specific industry in which the company operates and the role’s responsibilities – Visit the company’s website and social media pages to gather insights into its culture and values ### 2. Review the Job Description Meticulously – Carefully study the job description to understand the key requirements, duties, and expectations – Identify the skills, experiences, and qualifications that the employer is seeking – Highlight your skills and experiences that align with the job requirements in your resume and interview responses ### 3. Practice Answering Common Interview Questions – Anticipate common interview questions related to the role and prepare well-structured answers – Use the STAR (Situation, Task, Action, Result) method to effectively describe your experiences and accomplishments – Quantify your accomplishments and provide specific examples to demonstrate your impact ### 4. Research Industry Trends and Best Practices – Stay up-to-date on industry trends and best practices related to textile conditioning and tumbling processes – This knowledge will demonstrate your commitment to professional development and eagerness to contribute to the company’s success ### 5. Dress Professionally and Arrive on Time – First impressions matter, so dress professionally and punctually for the interview – Arrive at the interview venue with ample time to settle in and prepare yourself ### 6. Prepare Questions for the Interviewers – Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and company – Prepare questions about the company’s strategic goals, growth plans, or specific aspects of the role that you are curious aboutNext Step:

Armed with this knowledge, you’re now well-equipped to tackle the Conditioner Tumbler Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!