Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Conduit Bender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

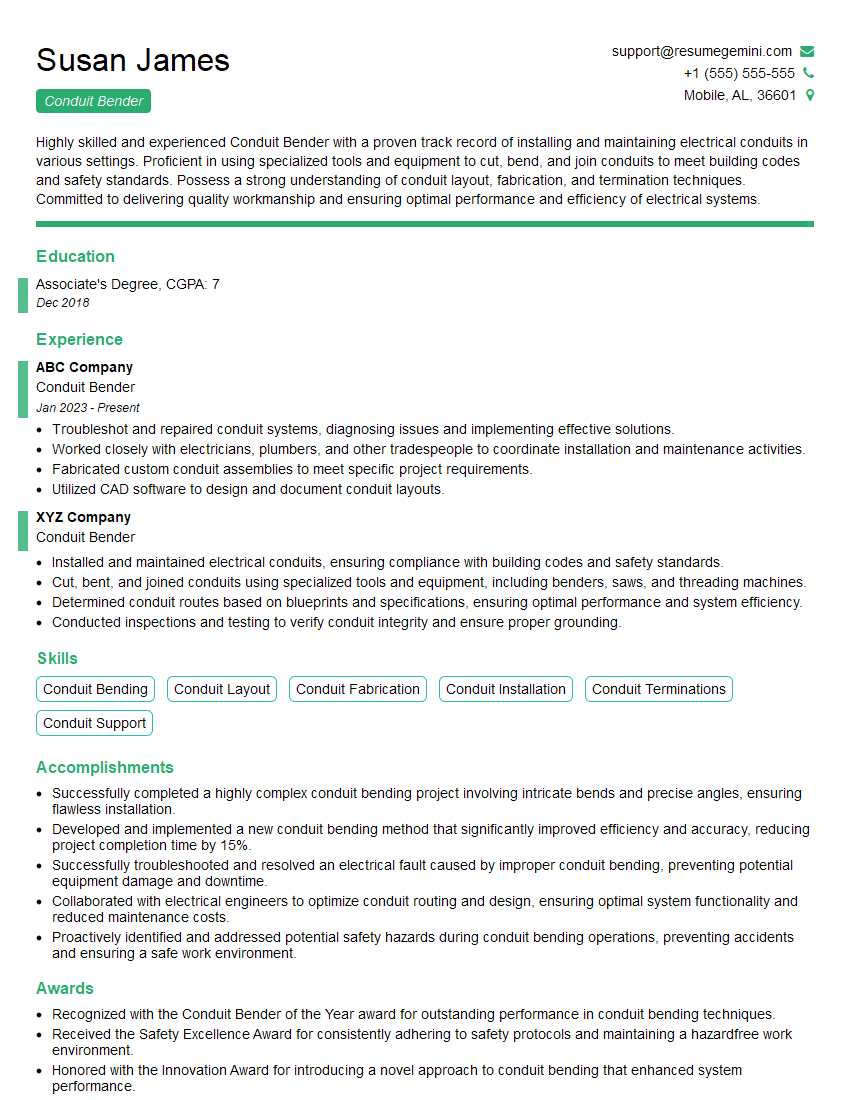

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conduit Bender

1. Describe the process of bending conduit?

The process of bending conduit involves several steps:

- Measuring and marking the conduit: Determine the desired bend radius and mark the conduit accordingly.

- Selecting the appropriate bender: Choose a bender with a radius that matches the desired bend.

- Inserting the conduit into the bender: Carefully insert the conduit into the bender, ensuring it is properly aligned.

- Bending the conduit: Slowly and evenly apply force to the bender, bending the conduit to the desired radius.

- Checking the bend: Inspect the bend to ensure it meets the required specifications.

2. What are the different types of conduit benders?

Manual benders:

- Hand bender: Suitable for small-diameter conduits, bent by hand.

- Ratchet bender: Requires less physical effort, allowing for precise bends in larger-diameter conduits.

Hydraulic benders:

- Hydraulic hand bender: Powered by a hydraulic pump, providing greater bending force.

- Hydraulic electric bender: Offers automated bending, reducing labor and increasing efficiency.

Specialized benders:

- Electrical benders: Designed for bending electrical conduits.

- EMT benders: Specifically used for bending electrical metallic tubing (EMT).

3. What factors influence the quality of a conduit bend?

- Radius: Ensuring the bend radius meets specifications is crucial for maintaining the integrity of the conduit.

- Bend angle: Precisely bending to the specified angle ensures proper alignment and prevents stress on the conduit.

- Ovality: Minimizing ovality during bending helps maintain the conduit’s structural integrity.

- Equipment: Using the correct bender and following proper procedures ensures accurate and consistent bends.

- Material quality: The type of conduit material (e.g., PVC, metal) influences its bending properties.

4. How do you handle multiple bends in a single conduit run?

- Plan the bend locations: Determine the optimal placement of bends to avoid unnecessary stress on the conduit.

- Use intermediate supports: Provide support at the intermediate bend points to prevent sagging and maintain the conduit’s shape.

- Stagger the bends: Alternate the bend directions to distribute stress evenly along the conduit.

- Allow for expansion and contraction: Consider the potential for temperature fluctuations and provide sufficient slack in the conduit to accommodate expansion and contraction.

5. What safety precautions should be taken when bending conduit?

- Wear appropriate PPE: Safety glasses, gloves, and hearing protection are essential.

- Secure the bender firmly: Ensure the bender is properly clamped or anchored to prevent movement during operation.

- Inspect the conduit: Check for any damage or imperfections before bending.

- Use proper bending techniques: Follow recommended bending procedures to avoid overbending or kinking the conduit.

- Be aware of surroundings: Ensure there are no obstructions or potential hazards in the work area.

6. How do you determine the correct conduit size for a specific application?

To determine the correct conduit size, consider the following factors:

- Number of wires: Calculate the total number of wires to be run through the conduit.

- Wire size: Refer to electrical codes to determine the appropriate conduit diameter based on the wire gauge.

- Fill ratio: Ensure the conduit is not overfilled, typically allowing for a fill ratio of 40-50%.

- Environmental conditions: Consider factors such as temperature, moisture, and potential hazards.

- Codes and regulations: Comply with all applicable electrical codes and standards for conduit sizing.

7. What types of materials are used in conduit manufacturing?

- PVC: Polyvinyl chloride is a lightweight, non-metallic material commonly used for electrical conduits in residential and commercial applications.

- Metal: Galvanized steel, aluminum, and stainless steel are durable and corrosion-resistant, suitable for both indoor and outdoor installations.

- Flexible metal: Liquid-tight flexible metal conduit (LFMC) provides protection in harsh conditions or where flexibility is required.

- Non-metallic flexible: Non-metallic flexible conduit (NMFC) is lightweight and easy to install, often used in data and communication applications.

- Fiberglass: Fiberglass reinforced plastic (FRP) conduit is corrosion-resistant and suitable for chemical environments.

8. What techniques can be used to troubleshoot common conduit bending issues?

- Ovality: Adjust the bending radius or use a bender with a smaller radius.

- Kinking: Inspect the conduit for damage or use a different bending technique.

- Overbending: Re-bend the conduit to the correct radius or replace the damaged section.

- Poor alignment: Ensure the bender is properly aligned and that the conduit is inserted correctly.

- Uneven bends: Check the bender for proper calibration or use a different bender.

9. Describe the different types of conduit fittings and their applications.

- Connectors: Used to join two conduit sections, available in various sizes and configurations.

- Elbows: Allow for changes in conduit direction, available in different angles.

- Couplings: Connect two conduits of the same size and type, providing a waterproof seal.

- Reducers: Reduce the conduit size at a connection point.

- Bushings: Protect wires from sharp edges or provide support at entry and exit points.

10. How do you stay up to date with the latest advancements and best practices in conduit bending?

- Attend industry events and conferences: Engage with experts and learn about new techniques and technologies.

- Read trade publications and online resources: Stay informed about advancements in the field.

- Seek professional development opportunities: Take courses or workshops to enhance skills and knowledge.

- Connect with peers and mentors: Exchange ideas and learn from experienced conduit benders.

- Follow industry standards and regulations: Ensure adherence to best practices and maintain compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conduit Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conduit Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conduit benders are responsible for bending and shaping metal conduit to create the necessary pathways for electrical wires and cables in a building.

1. Bending and shaping conduit

This is the primary responsibility of a conduit bender. They use a variety of tools and techniques to bend conduit to the correct shape and size.

- Use conduit benders to bend conduit to the desired shape and angle.

- Measure and mark conduit to ensure accurate bends.

2. Installing conduit

After the conduit is bent and shaped, the conduit bender must install it in the correct location.

- Install conduit in accordance with building codes and specifications.

- Secure conduit to walls, ceilings, and floors using straps, clips, and other hardware.

3. Troubleshooting and repairing conduit systems

Conduit benders are also responsible for troubleshooting and repairing conduit systems.

- Troubleshoot and repair conduit systems to ensure proper operation.

- Replace damaged conduit and fittings.

4. Maintaining conduit systems

Conduit benders are also responsible for maintaining conduit systems to ensure that they are in good working order.

- Inspect conduit systems for damage and wear and tear.

- Clean and lubricate conduit systems as needed.

Interview Tips

To help you ace your interview for a conduit bender position, here are some tips:

1. Research the company and the position

Before your interview, take some time to research the company you’re applying to and the specific conduit bender position you’re interested in. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their history, mission, and values.

- Read online reviews of the company to get a sense of what it’s like to work there.

- Talk to people in your network who may know about the company or the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Write out your answers to these questions and practice saying them out loud.

- Ask a friend or family member to mock interview you.

- Use online resources to find sample interview questions and answers.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re taking the opportunity seriously and that you’re respectful of their time.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location at least 10 minutes early so that you have time to check in and prepare.

4. Be yourself and be positive

The most important thing is to be yourself and be positive during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and be enthusiastic about the opportunity to work for the company.

- Answer the interviewer’s questions honestly and thoughtfully.

- Be positive and enthusiastic about the position and the company.

- Don’t be afraid to ask questions of your own.

Next Step:

Now that you’re armed with the knowledge of Conduit Bender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Conduit Bender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini