Feeling lost in a sea of interview questions? Landed that dream interview for Conduit Mechanic but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Conduit Mechanic interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

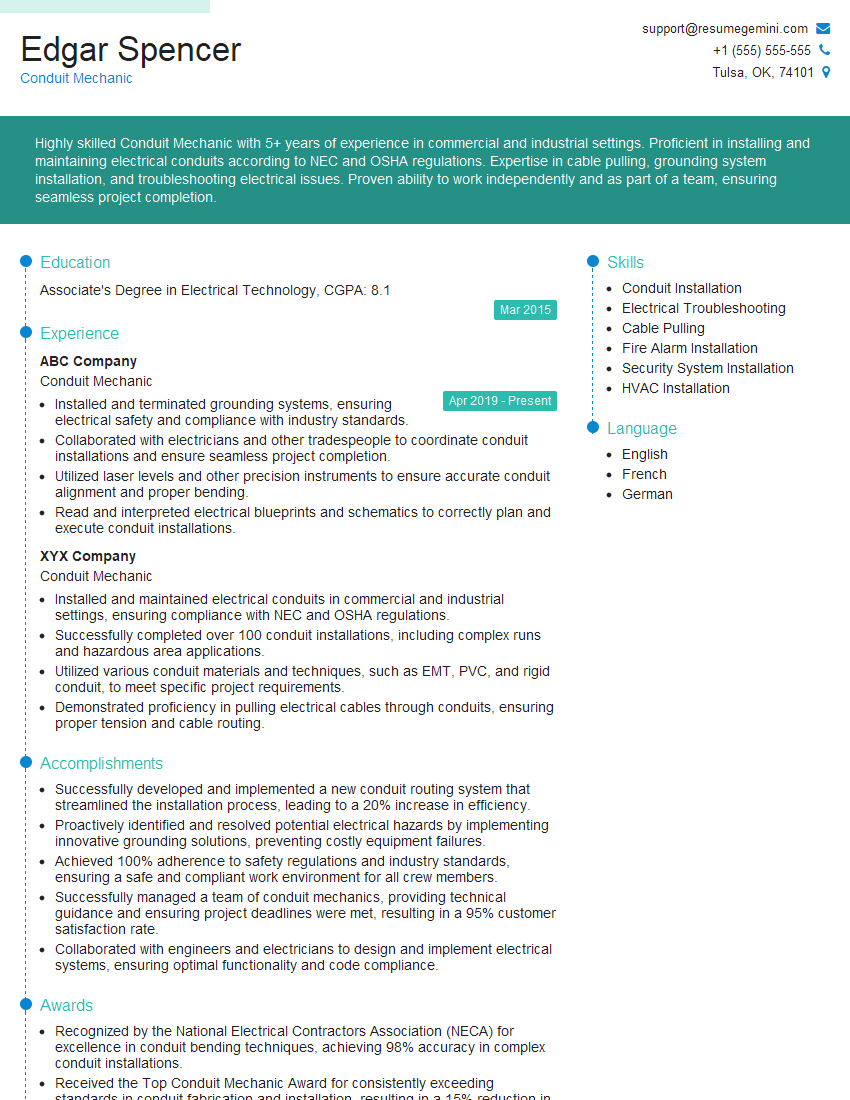

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conduit Mechanic

1. What are the different types of conduit systems and their applications?

There are three main types of conduit systems: rigid, intermediate, and flexible.

- Rigid conduit is made of metal and is used for protecting wires and cables in areas where they are exposed to physical damage, such as in industrial settings or outdoors.

- Intermediate conduit is made of plastic and is used for protecting wires and cables in areas where they are not exposed to physical damage, such as in residential or commercial buildings.

- Flexible conduit is made of metal or plastic and is used for protecting wires and cables in areas where they need to be able to move, such as in machinery or vehicles.

2. What are the different methods of bending conduit?

There are three main methods of bending conduit: hand bending, hydraulic bending, and electrical bending.

Hand bending

- Hand bending is the most common method of bending conduit and is done using a conduit bender.

- Conduit benders come in a variety of sizes and shapes, and the type of bender that is used will depend on the size and type of conduit that is being bent.

Hydraulic bending

- Hydraulic bending is a more powerful method of bending conduit than hand bending and is used for bending large or thick-walled conduit.

- Hydraulic benders use hydraulic pressure to bend conduit, and they are able to produce bends that are more precise and consistent than hand bending.

Electrical bending

- Electrical bending is a method of bending conduit using an electrical current.

- Electrical bending is used for bending small or thin-walled conduit, and it can produce bends that are very precise and consistent.

3. What are the different types of conduit fittings and their applications?

There are many different types of conduit fittings, and each type has a specific application.

- Couplings are used to connect two pieces of conduit together.

- Elbows are used to change the direction of a conduit run.

- Tees are used to connect three pieces of conduit together.

- Crosses are used to connect four pieces of conduit together.

- Reducers are used to reduce the size of a conduit run.

- Increasers are used to increase the size of a conduit run.

4. What are the different types of wire and cable and their applications?

There are many different types of wire and cable, and each type has a specific application.

- Solid wire is made of a single strand of metal and is used for applications where flexibility is not required, such as in electrical wiring.

- Stranded wire is made of multiple strands of metal and is used for applications where flexibility is required, such as in power cords.

- Coaxial cable is a type of cable that is used for transmitting high-frequency signals, such as in television and data communications.

- Fiber optic cable is a type of cable that is used for transmitting light signals, such as in telecommunications and data communications.

5. What are the different methods of installing conduit?

There are two main methods of installing conduit: surface mount and concealed.

Surface mount

- Surface mount conduit is installed on the surface of a wall or ceiling.

- Surface mount conduit is typically used in industrial or commercial settings where it is not possible to conceal the conduit.

Concealed

- Concealed conduit is installed inside a wall or ceiling.

- Concealed conduit is typically used in residential or commercial settings where it is desired to hide the conduit.

6. What are the different types of electrical enclosures and their applications?

There are many different types of electrical enclosures, and each type has a specific application.

- Panelboards are used to distribute electricity to a building.

- Switchboards are used to control the flow of electricity to a building.

- Motor control centers are used to control the operation of motors.

- Junction boxes are used to connect wires and cables together.

- Pull boxes are used to allow wires and cables to be pulled through a wall or ceiling.

7. What are the different types of electrical tools and their applications?

There are many different types of electrical tools, and each type has a specific application.

- Voltmeters are used to measure voltage.

- Ammeters are used to measure current.

- Ohmmeters are used to measure resistance.

- Continuity testers are used to test for continuity.

- Insulation testers are used to test for insulation resistance.

8. What are the different types of electrical safety hazards and how can they be prevented?

There are many different types of electrical safety hazards, and each type has a specific method of prevention.

- Electrical shock can be prevented by using proper grounding and insulation.

- Electrical fires can be prevented by using proper wiring and circuit protection.

- Arc flash can be prevented by using proper arc flash protection.

- Electrical explosions can be prevented by using proper explosion-proof equipment.

9. What are the different types of electrical codes and standards?

There are many different types of electrical codes and standards, and each type has a specific purpose.

- The National Electrical Code (NEC) is a set of regulations that governs the installation and use of electrical equipment in the United States.

- The International Electrotechnical Commission (IEC) is a set of international standards that govern the design and manufacture of electrical equipment.

- The Underwriters Laboratories (UL) is a safety certification organization that tests and certifies electrical equipment to ensure that it meets safety standards.

10. What are the different types of electrical troubleshooting techniques?

There are many different types of electrical troubleshooting techniques, and each type has a specific application.

- Visual inspection is the first step in any troubleshooting process.

- Voltage testing is used to check for voltage at different points in an electrical system.

- Continuity testing is used to check for continuity between two points in an electrical system.

- Insulation testing is used to check for insulation resistance between two points in an electrical system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conduit Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conduit Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conduit Mechanics, are responsible for planning, installing, and maintaining electrical raceways and the cabling within the conduits. They work according to the blueprints of the building under construction or renovation and they must have good knowledge of the standards and codes related to electrical installations in their location.

1. Planning and Layout

Interpret blueprints, schematics, and other technical documents to determine the appropriate layout of conduits and cables.

- Calculate the amount of materials needed for the job.

- Plan the route of the conduits, taking into account the location of walls, ceilings, and other obstacles.

2. Installation

Install conduits and cables according to the planned layout.

- Cut and bend conduits to the desired shape.

- Secure conduits to walls, ceilings, and other surfaces using straps, clips, and other hardware.

- Pull cables through conduits.

- Terminate cables and connect them to electrical devices.

3. Maintenance and Repair

Maintain and repair existing conduits and cables.

- Inspect conduits and cables for damage or wear and tear.

- Replace damaged or worn conduits and cables.

- Troubleshoot and repair electrical problems caused by faulty conduits or cables.

4. Safety

Follow all safety regulations and procedures related to electrical work.

- Wear proper safety gear, including gloves, safety glasses, and a hard hat.

- Use tools and equipment safely.

- Work in a safe manner, avoiding hazards such as electrical shocks and falls.

Interview Tips

Interviewing for a Conduit Mechanic position can be a daunting task, but with the right preparation, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific skills and experience required for the job.

- Visit the company’s website.

- Read articles about the company in the news or industry publications.

- Talk to people you know who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions.

- Be specific and provide examples.

- Tailor your answers to the specific job you are applying for.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills as a Conduit Mechanic. Be prepared to discuss your experience in detail, including the types of projects you have worked on and the skills you have developed.

- Quantify your experience whenever possible.

- Highlight your skills and experience that are most relevant to the job you are applying for.

- Be prepared to discuss your knowledge of electrical codes and standards.

4. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are interested and engaged.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for growth.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Conduit Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.