Feeling lost in a sea of interview questions? Landed that dream interview for Cone Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cone Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

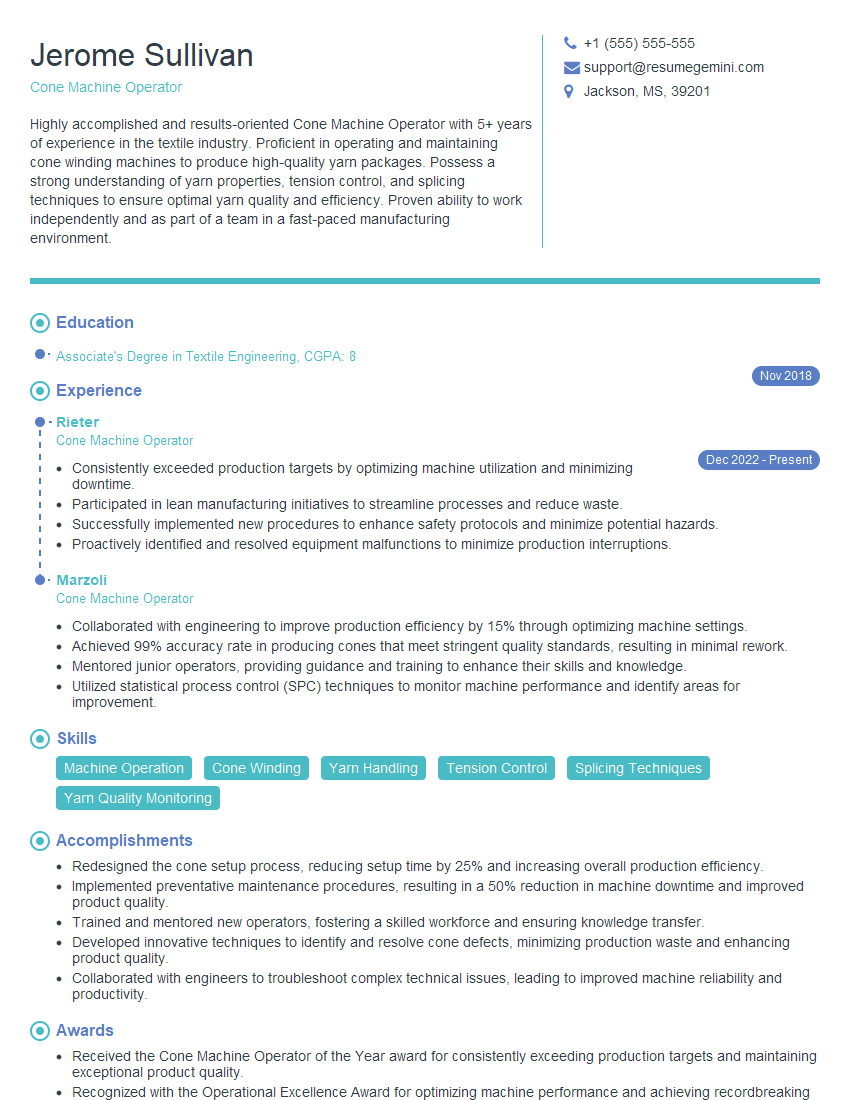

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cone Machine Operator

1. Describe the steps involved in setting up and operating a cone machine.

– Step 1: Gather materials and prepare the machine. First, I would gather all the necessary materials, including yarn, cones, and labels, and ensure that the machine is in good working order. – Step 2: Load the yarn onto the machine. The next step would be to load the yarn onto the machine and adjust the tension settings to ensure proper winding. – Step 3: Insert the empty cones onto the winding spindles. I would then insert empty cones onto the winding spindles and secure them in place. – Step 4: Start the winding process. Then, I would start the winding process by pressing the start button and monitoring the machine’s operation. The machine winds the yarn onto the cones at a predetermined speed and tension. – Step 5: Apply labels to the finished cones. Once the cones are wound, I would apply labels to them, indicating the yarn count, weight, and other necessary information. – Step 6: Inspect the finished cones. Finally, I would inspect the finished cones to ensure that they are wound evenly and meet the required quality standards.

2. What are the key parameters to consider when adjusting a cone machine for different types of yarn?

- Yarn tension: Different types of yarn require different levels of tension during winding to ensure proper winding and prevent breakage.

- Winding speed: The winding speed can affect the quality and consistency of the wound cones and needs to be adjusted based on the yarn type and desired output.

- Cone taper: The cone taper, or the angle of the cone’s sides, can vary depending on the yarn type and intended use.

- Traverse rate: The traverse rate, or the rate at which the winding head moves across the cone, can impact the evenness and density of the winding.

3. How do you troubleshoot common problems that may occur during cone winding?

- Yarn breakage: I would check for any obstructions in the yarn path, adjust the tension settings, or replace the yarn if necessary.

- Uneven winding: I would inspect the winding head for any damage or misalignment and adjust the traverse rate or tension settings to achieve even winding.

- Cone distortion: I would check the cone taper and winding speed settings to ensure they are appropriate for the yarn type and intended use.

- Labeling issues: I would inspect the labeling system for any malfunctions or errors and ensure that the labels are applied correctly and securely.

4. What are the safety precautions to be taken when operating a cone machine?

- Wear appropriate safety gear: I would always wear safety glasses, gloves, and proper clothing to protect myself from any potential hazards.

- Keep the work area clean and well-lit: A clean and well-lit work area helps prevent accidents and ensures that I can operate the machine safely.

- Inspect the machine before use: I would inspect the machine before each use to ensure that it is in good working order.

- Never reach into the machine while it is running: I would never put my hands or any objects into the machine while it is running to avoid injury.

5. Describe the maintenance procedures required for a cone machine.

- Regular cleaning: I would regularly clean the machine to remove any dust, yarn debris, or other contaminants that could affect its performance.

- Lubrication: I would lubricate the machine’s moving parts according to the manufacturer’s recommendations to ensure smooth operation.

- Checking and replacing worn parts: I would periodically check for any worn or damaged parts and replace them as necessary to maintain optimal performance.

- Calibration: I would calibrate the machine regularly to ensure that it is winding cones to the required specifications.

6. How do you calculate the yarn count and weight of a cone?

– Yarn count: The yarn count is calculated by dividing the length of the yarn in meters by its weight in grams. – Cone weight: The cone weight is determined by weighing the cone with the yarn wound on it and subtracting the weight of the empty cone.

7. What are the different types of cones used in the textile industry?

- Straight-sided cones: These cones have straight sides and are commonly used for winding cotton and synthetic yarns.

- Tapered cones: These cones have tapered sides and are often used for winding woolen and worsted yarns.

- Flanged cones: These cones have a flange or rim at the base and are used for winding delicate yarns that require additional support.

- Cheese cones: These cones have a cylindrical shape and are used for winding specialty yarns, such as embroidery threads.

8. What is the purpose of a cone creel?

A cone creel is a device used to hold and supply multiple cones of yarn to a textile machine. It ensures a continuous supply of yarn during the winding or weaving process and allows for efficient operation.

9. How do you ensure the quality of the cones produced by the cone machine?

- Regular inspections: I would conduct regular inspections of the cones to check for any defects, such as uneven winding, yarn breakage, or labeling errors.

- Testing: I would perform tests on the cones to verify their strength, tension, and other quality parameters.

- Calibration: I would calibrate the cone machine regularly to ensure that it is winding cones to the desired specifications and quality standards.

10. What are the latest advancements in cone machine technology?

- Automated cone winding: Advanced cone machines offer automated features, such as automatic cone loading and unloading, to improve efficiency and reduce labor costs.

- Precision winding: Newer cone machines have improved precision winding capabilities, allowing for more accurate and consistent winding of yarns.

- Data monitoring and analysis: Some cone machines have built-in data monitoring and analysis systems that can track production parameters, identify potential issues, and optimize the winding process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cone Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cone Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cone Machine Operator plays a crucial role in ensuring the smooth operation and maintenance of cone-making machinery. Their responsibilities encompass a wide range of tasks that are essential for efficient production.

1. Machine Operation

Cone Machine Operators are responsible for the safe and efficient operation of cone-making machines. This involves:

- Monitoring machine performance and making necessary adjustments to maintain optimal production levels.

- Feeding raw materials into the machine and ensuring a steady supply to prevent disruptions.

- Collecting and inspecting finished cones to ensure they meet quality standards.

2. Machine Maintenance

Cone Machine Operators are also responsible for basic maintenance of the cone-making machinery. This includes:

- Performing regular cleaning and lubrication to prevent malfunctions and extend machine lifespan.

- Identifying and reporting any potential maintenance issues to ensure timely repairs and minimize downtime.

- Assisting with major repairs and overhauls as needed to ensure the machine’s continued operation.

3. Production Quality Control

Cone Machine Operators are directly involved in ensuring the production of high-quality cones. This involves:

- Monitoring cone dimensions and thickness to meet specifications.

- Checking for defects, such as cracks, chips, or inconsistencies, and removing defective cones.

- Working with quality control personnel to identify and address any production issues that impact cone quality.

4. Safety and Compliance

Cone Machine Operators are responsible for adhering to all safety regulations and guidelines. This includes:

- Wearing appropriate safety gear and following proper safety procedures.

- Maintaining a clean and organized work area to prevent accidents.

- Reporting any safety concerns or incidents to supervisors immediately.

Interview Tips

Preparing thoroughly for an interview is essential for a successful outcome. Here are some tips to help candidates impress the interviewers and ace their Cone Machine Operator interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific requirements of the Cone Machine Operator role. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website to learn about their products, services, and industry standing.

- Read industry publications and articles to stay informed about the latest trends and technologies in cone manufacturing.

- Review the job description carefully to understand the key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that are most relevant to the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of your experience in operating cone-making machinery.

- Describe your knowledge of machine maintenance and troubleshooting techniques.

- Highlight your attention to detail and commitment to quality control.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your responses in advance. This will help you feel more confident and articulate during the interview.

- Tell me about your experience in operating cone-making machines.

- How do you ensure the production of high-quality cones?

- What are your safety priorities as a Cone Machine Operator?

4. Prepare Questions for the Interviewers

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions that demonstrate your curiosity and understanding of the role and company.

- What is the company’s vision for the future of cone manufacturing?

- What are the biggest challenges currently facing the cone industry?

- How does the company support the professional development of its employees?

5. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately for the interview and arrive on time. Maintain a positive and professional demeanor throughout the interview.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cone Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.