Are you gearing up for an interview for a Cone Treater position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cone Treater and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

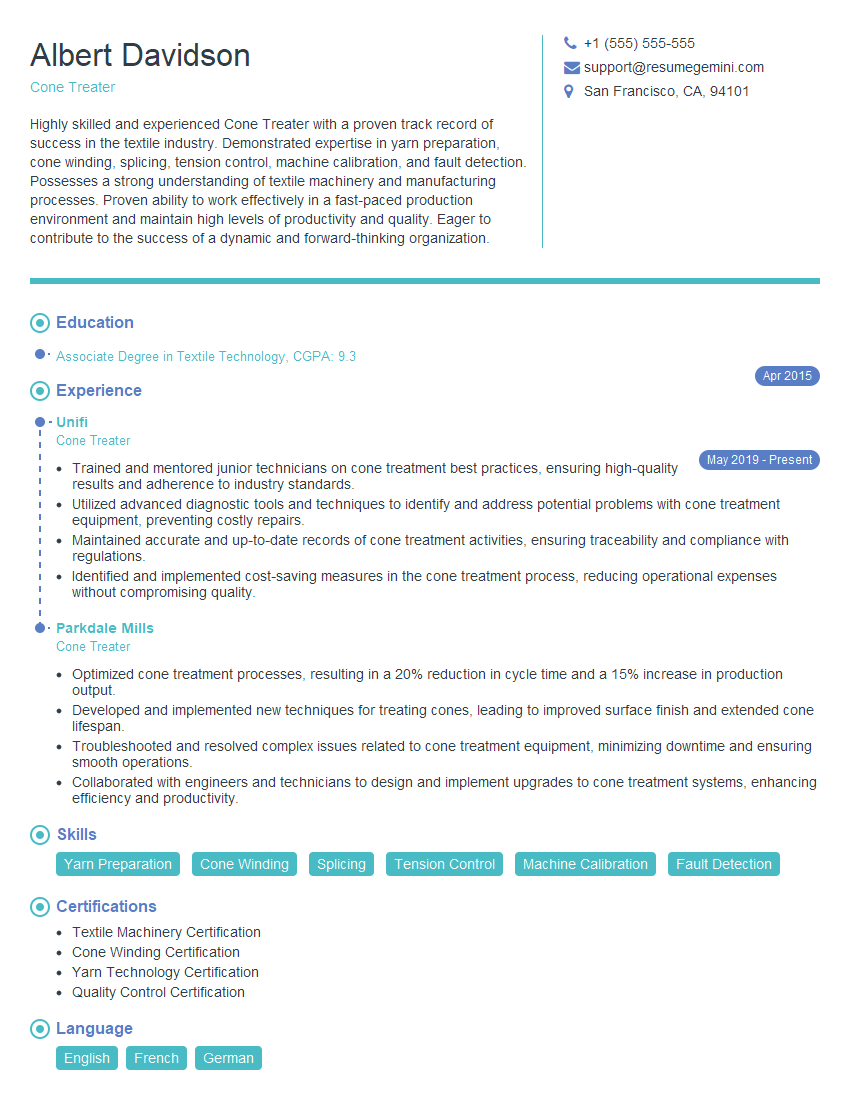

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cone Treater

1. Elaborate on the key responsibilities of a Cone Treater?

As a Cone Treater, my responsibilities encompass:

- Operating and maintaining cone treating machines, ensuring optimal performance and yarn quality

- Monitoring and adjusting process parameters such as temperature, tension, and chemical concentration to achieve desired yarn properties

- Preparing and mixing chemicals according to specified recipes, ensuring adherence to safety protocols

- Calibrating and troubleshooting equipment to identify and resolve any technical issues

- Adhering to quality control standards, conducting regular yarn inspections, and maintaining detailed records

2. Describe the different types of cone treating processes.

Yarn Sizing

- Applying a starch or synthetic-based solution to the yarn to improve its strength and abrasion resistance

- Enhancing yarn integrity for subsequent processes like weaving or knitting

Yarn Softening

- Utilizing chemical softeners to reduce yarn stiffness and improve its handle

- Enhancing yarn drape and flexibility for applications in garments or home textiles

Yarn Lubrication

- Applying lubricants to reduce friction during yarn processing

- Minimizing yarn breakage and wear during winding, twisting, or weaving

3. Explain the importance of proper chemical selection in cone treating.

Appropriate chemical selection is crucial for achieving desired yarn properties and ensuring efficient processing.

- The choice of chemical depends on the type of yarn, its intended use, and the desired effect

- Incorrect chemical selection can lead to poor yarn quality, production delays, or even equipment damage

- A thorough understanding of yarn chemistry and process parameters is essential

4. Discuss the environmental considerations associated with cone treating.

Cone treating involves the use of chemicals, which can potentially impact the environment.

- Proper waste management and disposal practices are crucial to minimize environmental impact

- Adhering to environmental regulations and industry best practices is essential

- Exploring eco-friendly alternatives and sustainable technologies can further reduce environmental footprint

5. Describe the safety protocols that must be followed during cone treating operations.

Cone treating involves working with chemicals and machinery, necessitating strict adherence to safety protocols.

- Proper personal protective equipment (PPE), including gloves, masks, and eye protection, must be worn

- Chemical handling and storage guidelines must be followed to prevent spills, leaks, or exposure

- Equipment should be regularly inspected and maintained to ensure safe operation

- Emergency response procedures must be known and practiced by all operators

6. Explain the role of quality control in cone treating.

Quality control is paramount in cone treating to ensure that treated yarn meets specifications.

- Regular yarn inspections are conducted to assess properties such as strength, elongation, and appearance

- Yarn samples are tested against defined standards to ensure compliance

- Quality control data is recorded and analyzed to identify areas for improvement and maintain consistent yarn quality

7. Describe the maintenance procedures required for cone treating machines.

Regular maintenance is crucial to ensure optimal machine performance and prevent breakdowns.

- Daily cleaning and lubrication of moving parts to minimize wear and tear

- Periodic inspections of electrical components, belts, and sensors to identify potential issues

- Calibration of temperature and tension controls to maintain process accuracy

- Regular replacement of worn or damaged parts to prevent machine downtime

8. Discuss the potential challenges faced during cone treating operations and how to overcome them.

Cone treating can present various challenges that require effective problem-solving skills.

- Yarn breakage can occur due to improper tension control or chemical imbalances. Adjusting parameters and optimizing chemical formulations can resolve this issue.

- Uneven treatment can result from clogged nozzles or inconsistent chemical application. Cleaning and inspecting machinery, as well as fine-tuning process parameters, can rectify this.

- Chemical spills or leaks can pose safety hazards. Prompt containment and cleanup, along with proper waste disposal, are crucial.

9. Explain the importance of teamwork in a cone treating environment.

Teamwork is essential in cone treating as it involves multiple processes and personnel.

- Effective communication and coordination between operators, supervisors, and quality control staff ensure smooth operations

- Collaborative problem-solving and knowledge sharing contribute to improved efficiency and yarn quality

- Teamwork fosters a supportive and productive work environment

10. Describe your experience in troubleshooting and resolving technical issues in cone treating.

Troubleshooting is an integral part of cone treating as technical issues can arise unexpectedly.

- I have encountered and resolved issues such as uneven treatment, yarn breakage, and chemical imbalances

- My approach involves identifying the root cause through systematic analysis of process parameters and equipment performance

- I utilize my knowledge of yarn chemistry and machine operation to implement effective solutions, minimizing downtime and maintaining yarn quality

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cone Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cone Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Cone Treater, you will be responsible for operating and maintaining cone treating equipment to prepare cone surfaces for winding yarn. Your duties include:

1. Machine Operation

Operate cone treating machines to apply chemicals and other treatments to fabric cones.

- Monitor machine settings to ensure proper application of treatments.

- Adjust machine parameters as needed to optimize treatment results.

2. Material Handling

Load and unload cones onto treating machines, ensuring proper loading and positioning.

- Handle and transport cones safely and efficiently.

- Inspect cones for defects before and after treatment.

3. Quality Control

Conduct quality checks on treated cones to ensure they meet specifications.

- Use testing equipment to measure treatment effectiveness.

- Identify and correct any deviations from quality standards.

4. Equipment Maintenance

Perform routine maintenance and cleaning of cone treating equipment.

- Troubleshoot and resolve minor equipment issues.

- Report any major equipment problems to supervisors.

Interview Tips

To prepare for your Cone Treater interview, consider the following tips:

1. Research the Company and Industry

Learn about the company’s history, products, and industry trends to demonstrate your interest and understanding of the field.

- Visit the company website and social media pages.

- Read industry publications and news articles.

2. Practice Common Interview Questions

Review common interview questions and prepare thoughtful answers that highlight your skills and experience relevant to the role.

- Questions about your cone treating experience.

- Questions about your knowledge of the textile industry.

- Questions about your quality control and problem-solving abilities.

3. Prepare Questions for the Interviewer

Asking informed questions shows your interest in the position and company. Prepare a few specific questions related to the role, the company, or the industry.

- Questions about the company’s cone treating process.

- Questions about the company’s plans for the future.

- Questions about the career advancement opportunities within the company.

4. Dress Professionally and Be on Time

First impressions matter, so dress appropriately for the interview and arrive on time. This shows that you respect the interviewer’s time and are serious about the opportunity.

- Wear business-casual attire.

- Be punctual and allow extra time for unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cone Treater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!