Are you gearing up for a career in Cone Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cone Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

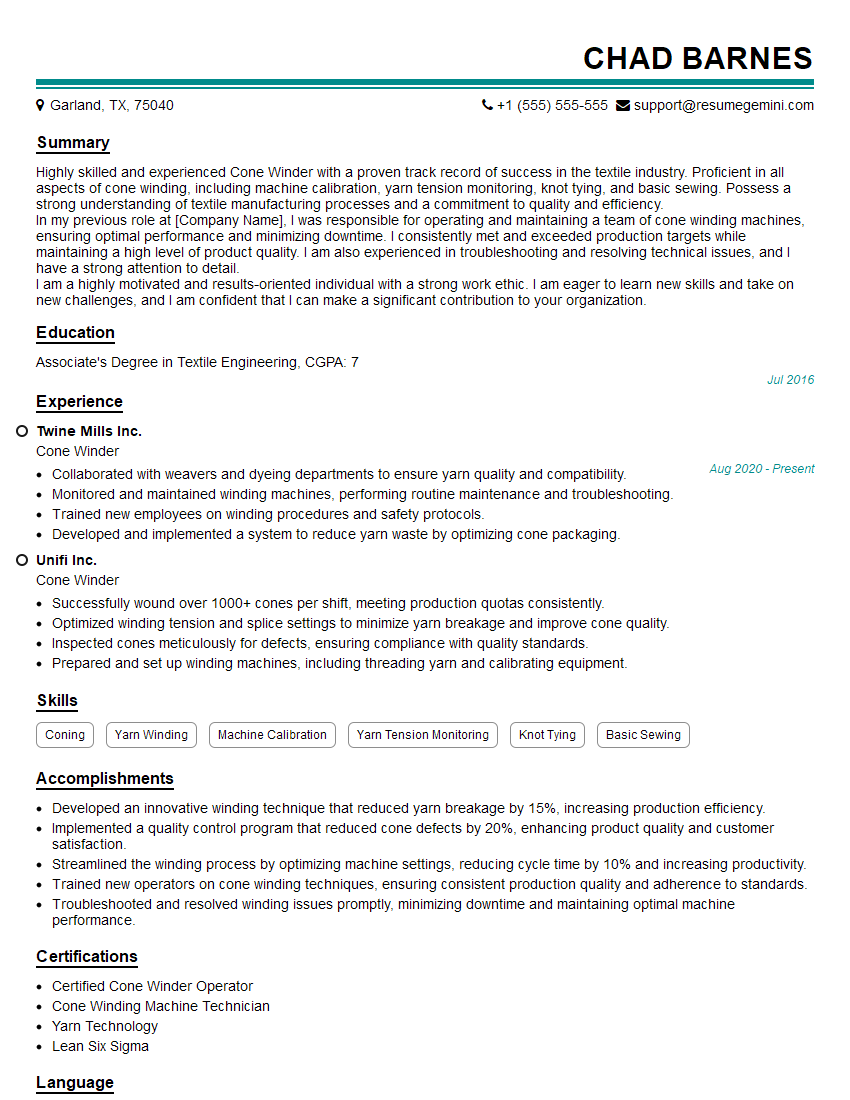

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cone Winder

1. What are the roles and responsibilities of a Cone Winder?

- Preparing and winding yarn onto empty cones.

- Monitoring the winding process and ensuring the yarn is wound evenly and tightly.

- Inspecting the wound yarn for any defects or imperfections.

- Ensuring the cones are labeled correctly.

- Maintaining and cleaning the winding equipment.

2. What are the different types of cone winding machines?

- Semi-automatic Cone Winder

- Fully-automatic Cone Winder

3. What are the factors that should be considered when winding yarn?

- Type of yarn

- Number of ends to be wound onto the cone

- Cone size

- Winding speed

- Tension

4. How do you ensure that the wound yarn meets the desired specifications?

- Setting the winding parameters correctly

- Inspecting the yarn at regular intervals during the winding process

- Testing the wound yarn to ensure it meets the specifications.

5. What are the common winding defects and how do you prevent them?

- Thin places and thick places: Caused by variations in the tension during winding. Can be prevented by maintaining a constant tension during winding.

- Loose yarn: Caused by insufficient tension during winding. Can be prevented by increasing the tension during winding.

- Yarn breakage: Caused by weak yarn or excessive tension during winding. Can be prevented by using strong yarn and maintaining a proper tension during winding.

6. What are the safety precautions that should be followed when operating a cone winding machine?

- Wear protective gear (e.g., safety glasses, gloves, earplugs).

- Keep the work area clean and tidy.

- Follow the manufacturer’s instructions for operating the machine.

- Do not attempt to repair or adjust the machine while it is running.

- Report any accidents or injuries to your supervisor immediately.

7. What is the importance of quality control in cone winding?

- Ensuring that the wound yarn meets the required specifications.

- Preventing defects and ensuring the smooth operation of downstream processes.

- Maintaining the reputation of the company.

8. What are the different quality control methods used in cone winding?

- Visual inspection

- Yarn testing (e.g., tensile strength, elongation, unevenness)

- Process monitoring (e.g., tension, speed)

9. How do you troubleshoot common winding problems?

- Yarn breakage – Check for weak yarn, excessive tension, or a dirty machine.

- Loose yarn – Check for insufficient tension, a dirty machine, or yarn that is too slippery.

- Uneven winding – Check for variations in tension, a dirty machine, or yarn that is not properly prepared.

10. What are the maintenance procedures for a cone winding machine?

- Cleaning the machine regularly

- Inspecting the machine for wear and tear

- Lubricating the machine according to the manufacturer’s instructions

- Calibrating the machine regularly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cone Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cone Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cone Winder is responsible for operating and maintaining cone winding machines used to wrap yarn onto cones. This role plays a crucial role in the textile industry, ensuring the smooth production of quality yarn.

1. Machine Operation

Cone Winders are proficient in operating and monitoring cone winding machines. Their duties include:

- Loading cones onto the machine and adjusting settings

- Monitoring yarn tension and making necessary adjustments

- Ensuring proper winding speed and quality

2. Machine Maintenance

Cone Winders are responsible for basic machine maintenance. Their responsibilities include:

- Cleaning and lubricating machines

- Conducting routine inspections and identifying potential issues

- Reporting any machine malfunctions or repairs to supervisors

3. Yarn Handling

Cone Winders are involved in handling and inspecting yarn during the winding process.

- Inspecting yarn for defects and ensuring quality standards

- Threading yarn onto machines and ensuring proper tension

- Removing finished cones from the machine and storing them properly

4. Quality Control

Cone Winders are responsible for maintaining the quality of the yarn wound onto cones.

- Checking the weight and dimensions of cones to ensure they meet specifications

- Ensuring cones are wound evenly and free of defects

- Maintaining accurate records of production quantities and quality checks

Interview Tips

To ace your Cone Winder interview, preparation is key. Here are some tips to help you:

1. Research the Role and Company

Take the time to thoroughly research the Cone Winder role and the company you are applying to.

- Understand the specific responsibilities of a Cone Winder in the textile industry.

- Learn about the company’s products, values, and culture.

- Check their website, social media, and industry news for insights.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions related to the Cone Winder role.

- Why are you interested in this position and why do you think you are a good fit?

- Describe your experience with cone winding machines and yarn handling.

- How do you ensure the quality of the yarn wound onto cones?

3. Dress Professionally and Arrive Punctually

First impressions matter. Dress in appropriate attire and arrive punctually for your interview.

- Wear clean and pressed business casual clothing.

- Be respectful of the interviewer’s time and arrive a few minutes early.

- Maintain a polite and professional demeanor throughout the interview.

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a small gesture that can leave a lasting impression.

- Express your gratitude for the opportunity to interview.

- Reiterate your interest in the position and emphasize your qualifications.

- Inquire about the next steps in the hiring process and follow up if you don’t hear back within a reasonable time frame.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cone Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!