Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Construction Ironworker Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

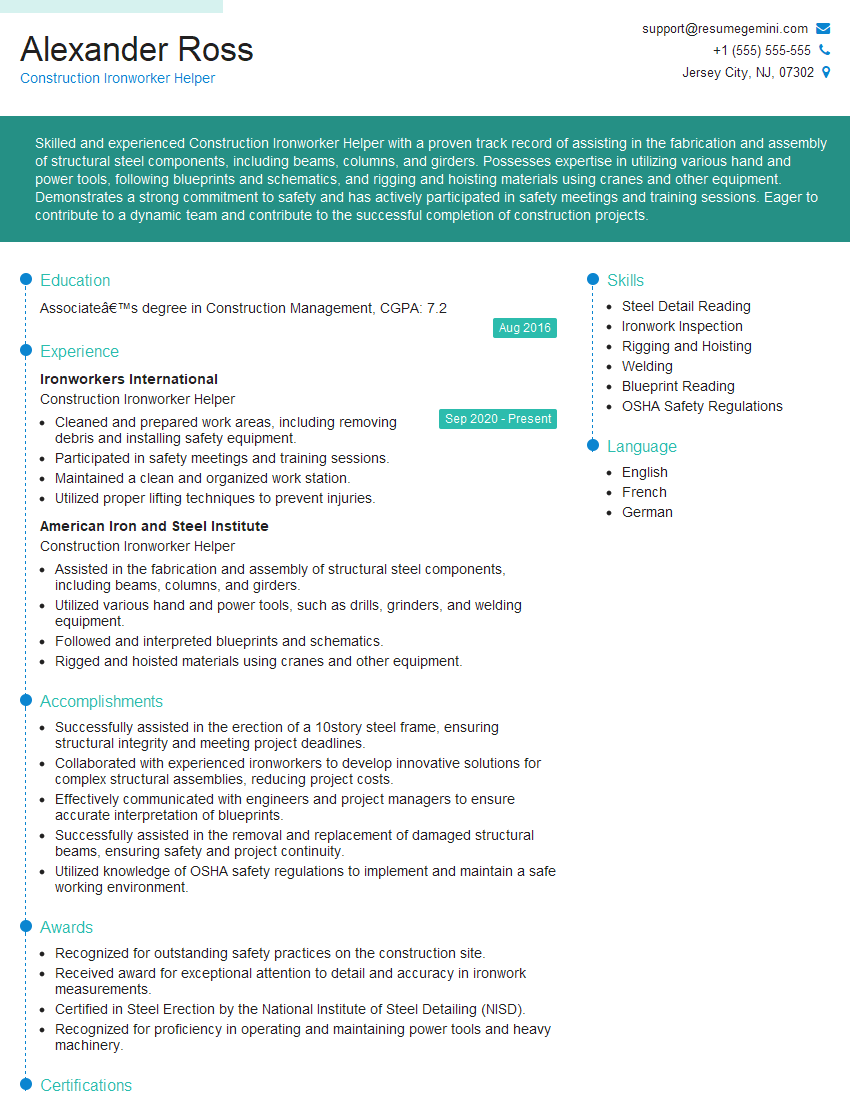

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Construction Ironworker Helper

1. Describe the main responsibilities of a Construction Ironworker Helper?

As a Construction Ironworker Helper, my responsibilities would include:

- Assisting ironworkers in the fabrication, assembly, and erection of structural steel and metal components.

- Operating and maintaining tools and equipment used in ironworking, such as cranes, hoists, and welding machines.

- Inspecting and maintaining ironwork for safety and quality control.

- Performing general labor tasks, such as material handling, cleanup, and setup.

2. What are the safety precautions that must be taken when working as a Construction Ironworker Helper?

Proper Training and Certification

- Undergo formal training and obtain certifications in ironworking and related safety practices.

- Stay up-to-date on industry standards and regulations.

Hazard Recognition and Control

- Identify and assess potential hazards on the job site.

- Implement appropriate control measures, such as using fall protection equipment, wearing protective gear, and following safe work procedures.

Personal Protective Equipment (PPE)

- Wear required PPE, including hard hats, safety glasses, gloves, and steel-toed boots.

- Inspect and maintain PPE regularly to ensure its effectiveness.

3. What is the importance of following blueprints and specifications in ironworking?

Following blueprints and specifications is crucial in ironworking for several reasons:

- Ensures accuracy: Blueprints provide detailed instructions and measurements, ensuring that ironworkers fabricate and assemble structures according to design specifications.

- Maintains quality: Specifications outline the materials, tolerances, and quality standards that must be met. By adhering to these requirements, ironworkers can deliver high-quality structures.

- Prevents errors: Following blueprints and specifications minimizes the risk of errors and rework, reducing project delays and costs.

- Facilitates communication: Blueprints and specifications serve as a common language between designers, engineers, and ironworkers, facilitating effective communication and ensuring everyone is on the same page.

4. How do you perform a proper vertical weld?

- Prepare the joint by cleaning and beveling the edges.

- Select the appropriate welding rod and set the correct welding parameters.

- Start the weld at the bottom of the joint and move upwards in a straight line.

- Maintain a consistent welding speed and angle to ensure proper penetration and bead formation.

- Use a whipping motion to prevent the weld pool from becoming too large and sagging.

- Inspect the weld for quality, including penetration, bead shape, and any defects.

5. Describe the different types of welding processes used in ironworking?

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, uses a consumable electrode covered in flux.

- Gas Metal Arc Welding (GMAW): Also known as MIG welding, uses a continuously fed wire electrode and a shielding gas.

- Flux-Cored Arc Welding (FCAW): Similar to GMAW but uses a tubular electrode filled with flux.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, uses a non-consumable tungsten electrode and a shielding gas.

- Submerged Arc Welding (SAW): Uses a consumable electrode submerged in a granular flux.

6. How do you interpret welding symbols on blueprints?

Interpreting welding symbols on blueprints is essential for fabricating and assembling ironwork structures. These symbols provide information about the type of weld, its size, location, and any additional requirements.

- Identify the basic weld symbol, which indicates the type of weld (e.g., fillet, groove, etc.).

- Pay attention to the dimensions and tolerances specified in the symbol.

- Look for any additional symbols or annotations that provide supplementary information, such as weld quality requirements or inspection criteria.

7. How do you calculate the weight of a steel beam?

To calculate the weight of a steel beam, I would use the following formula:

Weight (lbs) = {(Width (in) x Height (in)) / 2.65} x Length (ft)

- Measure the width, height, and length of the steel beam in inches and feet.

- Substitute the values into the formula.

- Calculate the weight in pounds.

8. Describe the process of rigging ironwork materials.

- Planning: Determine the best rigging method and equipment for the task.

- Preparing the materials: Attach slings, hooks, and other rigging hardware securely to the ironwork materials.

- Positioning the materials: Use cranes, hoists, or other equipment to lift and move the materials into place.

- Securing the materials: Once in place, secure the materials using bolts, pins, or other fasteners.

- Inspecting the rigging: Regularly inspect the rigging setup for safety and ensure it is secure before lifting or moving any materials.

9. What are the different types of ironwork connections?

- Bolted connections: Use bolts to connect ironwork members.

- Welded connections: Use welding to join ironwork members.

- Riveted connections: Use rivets to connect ironwork members (less common in modern construction).

- Pinned connections: Use pins to connect ironwork members, allowing for some movement or disassembly.

10. How do you ensure the structural integrity of ironwork constructions?

- Proper design: Ensure that the ironwork structure is designed by a qualified engineer to meet all applicable building codes and standards.

- Quality materials: Use high-quality ironwork materials that meet industry specifications.

- Skilled workmanship: Employ experienced and certified ironworkers who follow best practices in fabrication, assembly, and erection.

- Regular inspections: Conduct regular inspections of the ironwork structure to identify any potential issues or damage.

- Maintenance and repairs: Perform timely maintenance and repairs to address any issues that may arise, ensuring the ongoing structural integrity of the construction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Construction Ironworker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Construction Ironworker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Construction Ironworker Helpers are an essential part of the ironworking process. They provide support to Ironworkers and are responsible for various tasks on job sites. This role requires an individual with physical strength, attention to detail, and a willingness to work in a demanding environment. Key job responsibilities include:1. Assisting Ironworkers

Ironworker Helpers assist Ironworkers in the installation, fabrication, and repair of structural iron and steel components. They may perform tasks such as:

- Carrying and hoisting materials using hoists, cranes, and forklifts.

- Positioning and aligning structural members, beams, and girders.

- Setting up scaffolding and rigging equipment.

2. Material Handling

Helpers are responsible for handling and managing various materials on construction sites, including:

- Unloading and distributing materials from delivery trucks.

- Setting up and maintaining material storage areas.

- Ensuring materials are properly stored and accounted for.

3. Site Preparation and Maintenance

Ironworker Helpers also assist with site preparation and maintenance. They may perform tasks such as:

- Cleaning and sweeping work areas.

- Setting up temporary structures like barricades and safety netting.

- Maintaining tools and equipment.

4. Safety and Compliance

Construction Ironworker Helpers must prioritize safety and comply with all safety regulations and procedures on construction sites. This includes:

- Wearing proper safety gear, including hard hats, safety glasses, and gloves.

- Following established safety protocols for working at heights.

- Reporting any hazards or unsafe conditions to supervisors.

Interview Tips

To ace the interview for a Construction Ironworker Helper position, candidates should prepare thoroughly and present themselves confidently. Here are some tips to help candidates succeed:1. Research the Company and Industry

Before the interview, candidates should research the construction company and the ironworking industry. They should familiarize themselves with the company’s projects, safety record, and industry trends. This demonstrates their interest in the company and the role.

2. Practice Common Interview Questions

Candidates should practice answering common interview questions related to their skills, experience, and qualifications. They should prepare clear and concise responses that highlight their relevant abilities and strengths.

3. Emphasize Physical Fitness and Endurance

Construction Ironworker Helpers must have physical strength and endurance to perform demanding tasks. Candidates should emphasize their physical fitness during the interview and discuss their ability to lift heavy objects and work in challenging conditions.

4. Highlight Safety Awareness and Compliance

Safety is paramount in the construction industry. Candidates should demonstrate their understanding of safety protocols and regulations. They should mention any safety training or certifications they have obtained.

5. Ask Thoughtful Questions

At the end of the interview, candidates should ask thoughtful questions to show their engagement and interest in the role. Questions about the company’s safety culture, training opportunities, or project pipeline can demonstrate their enthusiasm and desire to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Construction Ironworker Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.