Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Construction Materials Testing Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

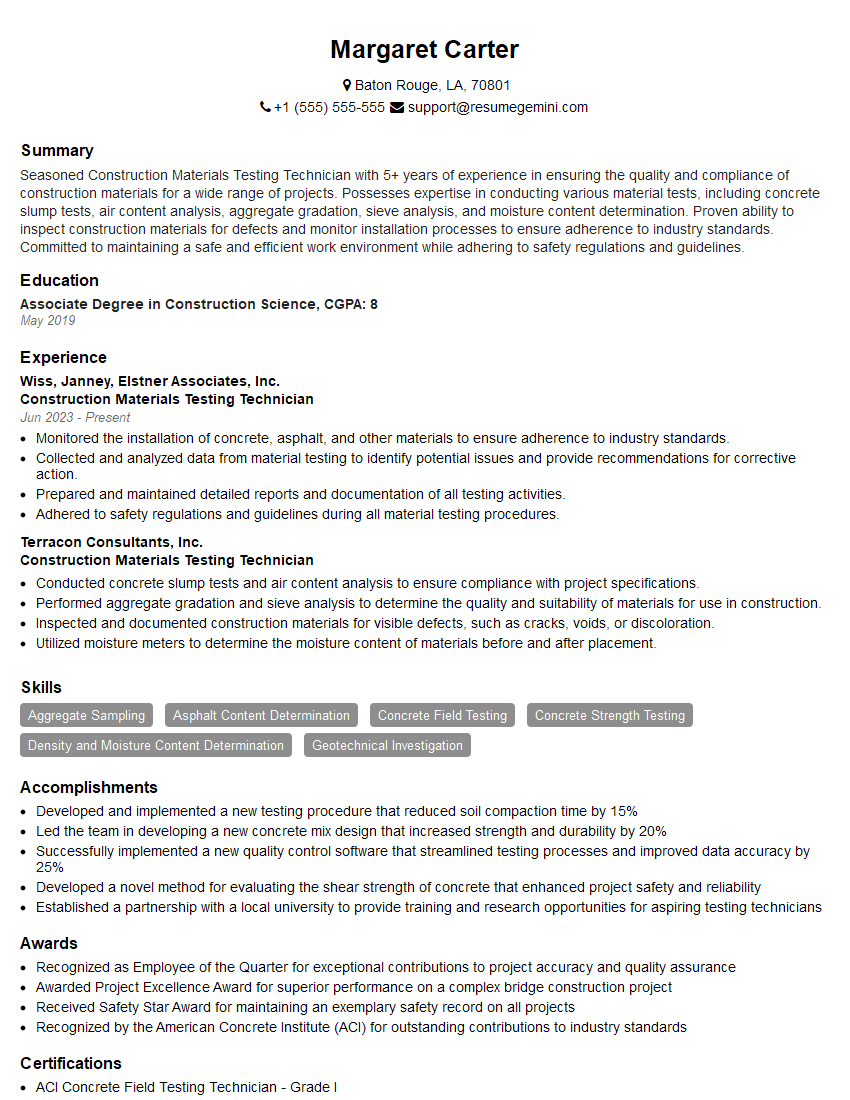

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Construction Materials Testing Technician

1. Describe the procedure for conducting a compressive strength test on concrete cylinders?

Sample answer: 1. Prepare the concrete cylinders: Make sure the cylinders are properly cured and have reached the desired testing age. 2. Set up the testing apparatus: Position the cylinder in the testing machine and align it properly. 3. Apply the load: Gradually apply a compressive load to the cylinder until it fails. 4. Record the data: Note the maximum load applied and the corresponding failure mode. 5. Calculate the compressive strength: Determine the compressive strength by dividing the maximum load by the cross-sectional area of the cylinder.

2. How do you test the flexural strength of concrete beams?

Sample answer: 1. Prepare the concrete beams: Ensure the beams are properly cured and have reached the desired testing age. 2. Set up the testing apparatus: Place the beam in the testing machine and support it with rollers or knife edges. 3. Apply the load: Apply a load at the center of the beam and gradually increase it until failure. 4. Record the data: Note the maximum load applied and the corresponding failure mode. 5. Calculate the flexural strength: Determine the flexural strength using the appropriate formula based on the dimensions and loading conditions.

3. What are the key properties you evaluate when testing cement?

Sample answer: – Fineness: Fineness affects the workability, strength, and durability of concrete. – Setting time: The setting time determines the time frame for placing and finishing concrete. – Strength: Compressive and flexural strength are crucial for structural applications. – Soundness: Soundness tests ensure the cement is free from harmful expansions or contractions. – Consistency: Consistency tests assess the flowability and workability of cement.

4. How do you determine the moisture content of soil using the oven-drying method?

Sample answer: 1. Take a representative soil sample: Collect a sample that accurately represents the moisture content of the soil. 2. Weigh the wet soil: Determine the initial weight of the wet soil sample. 3. Dry the soil in an oven: Place the soil sample in an oven at a specified temperature until it reaches constant weight. 4. Cool and weigh the dry soil: Allow the soil sample to cool and then weigh it to obtain the dry weight. 5. Calculate the moisture content: Determine the moisture content as a percentage by subtracting the dry weight from the wet weight and dividing by the dry weight.

5. What is the Proctor compaction test, and how do you perform it?

Sample answer: The Proctor compaction test determines the optimal moisture content and maximum dry density of a soil. The procedure involves: – Molding soil samples at varying moisture contents: Compact soil samples at different moisture levels using a specific compactive effort. – Measuring the dry density and moisture content of each sample: Determine the dry density by dividing the dry weight by the volume of the compacted sample. – Plotting the dry density vs. moisture content data: Create a compaction curve that shows the relationship between dry density and moisture content. – Determining the maximum dry density and optimal moisture content: Identify the point on the curve representing the highest dry density and corresponding moisture content.

6. Describe the purpose and procedure of the California Bearing Ratio (CBR) test.

Sample answer: The CBR test evaluates the strength and deformation characteristics of subgrade and base materials for road construction. The procedure includes: – Preparing a soil sample: Compact the soil sample in a cylindrical mold at a specified density and moisture content. – Soaking the sample: Subject the compacted sample to a period of soaking to simulate field conditions. – Applying a load to the sample: Gradually apply a load to the soaked sample using a plunger. – Measuring the penetration: Record the penetration of the plunger into the sample at various load levels. – Calculating the CBR: Determine the CBR value by comparing the penetration values to those of a standard crushed stone material.

7. How do you interpret the results of an aggregate gradation test?

Sample answer: – Particle size distribution: The gradation curve shows the percentage of aggregate particles within different size ranges. – Uniformity coefficient and coefficient of curvature: These coefficients indicate the uniformity and curvature of the gradation. – Fineness modulus: The fineness modulus is a single value that represents the overall fineness of the aggregate. – Optimum aggregate proportions: Based on the gradation, you can determine the ideal proportions of different aggregate sizes for specific applications.

8. What are the different types of asphalt tests, and what do they evaluate?

Sample answer: – Penetration test: Evaluates the consistency and hardness of asphalt. – Viscosity test: Measures the flow characteristics of asphalt. – Ductility test: Assesses the stretching and flexibility of asphalt. – Flash point test: Determines the temperature at which asphalt gives off flammable vapors. – Specific gravity and density test: Measures the weight and volume relationships of asphalt.

9. How do you conduct a skid resistance test on a pavement surface?

Sample answer: – Selecting the test method: Choose a skid resistance test method, such as the ASTM E274 or ASTM E303. – Preparing the test surface: Clean and dry the pavement surface before testing. – Operating the skid resistance tester: Follow the manufacturer’s instructions to conduct the test. – Recording the data: Measure and record the skid resistance values obtained from the tester. – Evaluating the results: Interpret the skid resistance values based on established standards and guidelines.

10. What is the importance of quality control in construction materials testing?

Sample answer: – Ensures compliance with specifications: Testing verifies that materials meet the required standards and specifications. – Improves project quality: Quality testing helps identify and mitigate potential issues, leading to better construction outcomes. – Reduces risks: By testing materials before use, it reduces the risk of accidents or failures due to inadequate material performance. – Provides documentation: Test results provide evidence of the quality and suitability of materials used in construction. – Facilitates decision-making: Test data supports decision-making during construction, such as determining the acceptability of materials or adjusting construction practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Construction Materials Testing Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Construction Materials Testing Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Construction Materials Testing Technicians play a crucial role in the construction industry, ensuring the quality of materials used in various projects. Their key responsibilities encompass a wide range of tasks, including:

1. Material Testing

Conduct comprehensive tests on construction materials such as concrete, asphalt, soil, and aggregates to assess their properties and compliance with specifications.

2. Equipment Calibration and Maintenance

Calibrate and maintain testing equipment regularly to ensure accuracy and reliability of test results.

3. Data Analysis and Reporting

Analyze test results and prepare detailed reports, providing recommendations on material suitability and usage.

4. Field Inspections

Visit construction sites to collect samples, conduct field tests, and monitor material usage and installation.

5. Quality Control

Implement and maintain quality control procedures to ensure compliance with project specifications and industry standards.

6. Troubleshooting and Problem Solving

Identify and resolve material-related issues during construction, providing technical support to project teams.

7. Safety and Compliance

Adhere to safety protocols and comply with industry regulations related to material testing and handling.

Interview Tips

Preparing thoroughly for an interview can significantly enhance your chances of success. Here are some essential tips to help you ace the interview for a Construction Materials Testing Technician position:

1. Research the Company and Industry

Familiarize yourself with the company’s history, projects, and industry trends. This demonstrates your interest and enthusiasm for the role.

2. Highlight Relevant Experience

Emphasize your hands-on experience in construction materials testing, including specific techniques and equipment you have used. Quantify your accomplishments whenever possible.

3. Showcase Your Technical Skills

Discuss your proficiency in testing methods, data analysis, and report writing. Mention any certifications or training you have obtained.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare well-thought-out answers. Examples include: “Why are you interested in this role?” and “What is your understanding of quality control in construction?”

5. Practice Your Communication Skills

Practice your communication skills by rehearsing answers out loud and seeking feedback from a friend or family member. Clear and concise communication is crucial.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. This demonstrates your respect for the company and the position.

7. Ask Questions

At the end of the interview, ask thoughtful questions about the company, the role, and the team you would be joining. This shows your engagement and interest.

Next Step:

Now that you’re armed with the knowledge of Construction Materials Testing Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Construction Materials Testing Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini