Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Continuous Linter-Drier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

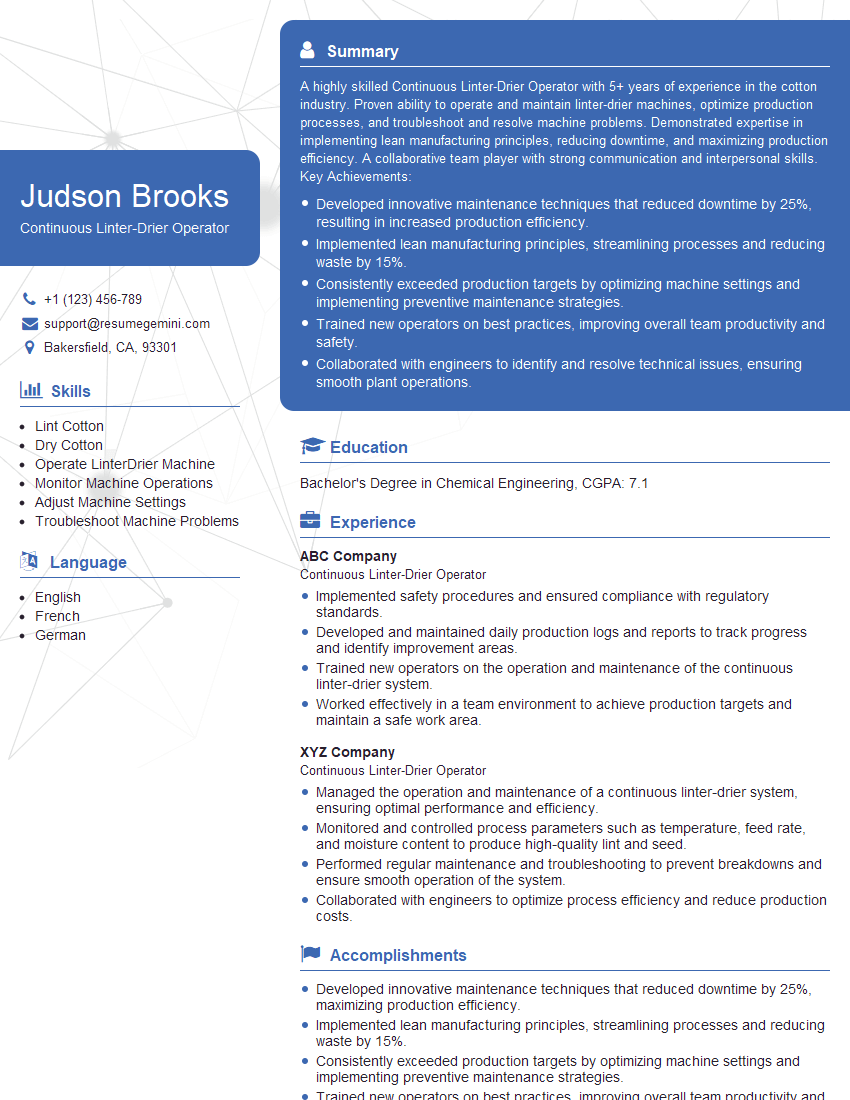

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Linter-Drier Operator

1. What are the key responsibilities of a Continuous Linter-Drier Operator?

As a Continuous Linter-Drier Operator, my primary responsibilities would include:

- Operating and monitoring linter-drier equipment to remove impurities and moisture from cotton

- Maintaining and calibrating equipment to ensure optimal performance and efficiency

2. Describe the process of linter removal from cotton.

Pre-Cleaning

- Removing large debris and impurities using screens and beaters

Linting

- Passing cotton through saw-toothed cylinders to remove short fibers (linters)

- Separating linters from cotton using air currents

Drying

- Exposing cotton to heated air to reduce moisture content

- Ensuring proper temperature control to prevent fiber damage

3. What are the safety precautions you observe while operating linter-drier equipment?

- Wearing appropriate personal protective equipment (PPE)

- Following lockout/tagout procedures before maintenance

- Maintaining a clean and organized work area

- Being aware of potential hazards, such as fire, electrical shocks, and moving machinery

4. How do you monitor the quality of the finished product?

- Visually inspecting the cotton for cleanliness and dryness

- Using moisture meters to ensure desired moisture levels

- Taking samples for laboratory analysis to verify fiber quality

- Maintaining records of quality control checks

5. What is the importance of proper moisture control in the linter-drying process?

- Prevents fiber damage and discoloration

- Ensures optimal spinning performance

- Reduces the risk of mold and mildew growth

- Facilitates proper packaging and storage

6. Describe the maintenance procedures you follow to keep the linter-drier equipment in good working condition.

- Regularly cleaning and lubricating moving parts

- Inspecting and replacing worn or damaged components

- Calibrating sensors and instruments

- Conducting preventive maintenance checks to identify potential issues

7. How do you handle equipment malfunctions or breakdowns?

- Immediately stopping the equipment to prevent further damage

- Identifying the source of the problem using troubleshooting techniques

- Repairing or replacing faulty components

- Reporting the incident to supervisors and maintaining a record of repairs

8. Discuss the importance of teamwork and communication in the linter-drying process.

- Coordinating with other operators to ensure smooth production

- Communicating quality issues and maintenance needs to supervisors and colleagues

- Sharing knowledge and expertise to improve processes

- Maintaining a positive and collaborative work environment

9. How do you stay updated on industry best practices and technological advancements in the field?

- Attending training and workshops

- Reading industry publications and journals

- Networking with other professionals

- Exploring new technologies and automating processes

10. What motivates you to excel as a Continuous Linter-Drier Operator?

- Passion for the cotton industry and understanding its significance

- Desire to produce high-quality cotton products

- Commitment to safety and efficiency in the workplace

- Drive to continuously improve processes and optimize performance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Linter-Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Linter-Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Continuous Linter-Drier Operators are responsible for operating and maintaining the continuous linter-drier machine, which separates cotton fibers from cottonseed and dries the fibers.

1. Operate and Maintain Equipment

Operate and maintain the continuous linter-drier machine, including starting, stopping, and monitoring the machine’s operation.

- Monitor the machine’s sensors and gauges to ensure that it is operating properly.

- Identify and troubleshoot any problems with the machine and perform necessary repairs.

2. Inspect and Grade Cotton

Inspect and grade cotton fibers produced by the machine to ensure that they meet quality standards.

- Check the fibers for moisture content, color, and other quality factors.

- Separate the fibers into different grades based on their quality.

3. Maintain Work Area

Maintain a clean and safe work area around the continuous linter-drier machine.

- Clean and lubricate the machine regularly.

- Dispose of waste materials and debris properly.

4. Follow Safety Procedures

Follow all safety procedures and regulations related to the operation of the continuous linter-drier machine.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Lock out and tag out the machine before performing any maintenance or repairs.

Interview Tips

To ace an interview for a Continuous Linter-Drier Operator position, you should be prepared to discuss your experience and skills in operating and maintaining linter-drier machines, as well as your knowledge of cotton fiber quality standards.

1. Emphasize Your Experience

Highlight your experience in operating and maintaining continuous linter-drier machines. Be specific about the types of machines you have worked on and the tasks you were responsible for.

- Example: “In my previous role, I was responsible for operating and maintaining a continuous linter-drier machine that produced cotton fibers for a major textile manufacturer. I was responsible for all aspects of the machine’s operation, including monitoring the machine’s sensors and gauges, troubleshooting problems, and performing necessary repairs.”

2. Showcase Your Knowledge

Demonstrate your knowledge of cotton fiber quality standards. Be able to discuss the different factors that affect cotton fiber quality, such as moisture content, color, and length.

- Example: “I am familiar with the USDA cotton fiber quality standards and I have experience in inspecting and grading cotton fibers. I can identify and separate cotton fibers into different grades based on their quality.”

3. Be Prepared to Discuss Safety

Be prepared to discuss your knowledge of safety procedures and regulations related to the operation of continuous linter-drier machines. Be able to explain how you follow these procedures to ensure the safety of yourself and others.

- Example: “I am aware of all safety procedures and regulations related to the operation of continuous linter-drier machines. I always wear appropriate PPE and I follow all lockout/tagout procedures before performing any maintenance or repairs.”

4. Be Enthusiastic and Eager to Learn

Show the interviewer that you are enthusiastic about the Continuous Linter-Drier Operator position and that you are eager to learn more about the industry. Ask questions about the company and the position to demonstrate your interest.

- Example: “I am very excited about the opportunity to work as a Continuous Linter-Drier Operator for your company. I am eager to learn more about the cotton industry and I am confident that I can be a valuable asset to your team.”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Continuous Linter-Drier Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Continuous Linter-Drier Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.