Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Continuous Mining Machine Lode Miner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Continuous Mining Machine Lode Miner so you can tailor your answers to impress potential employers.

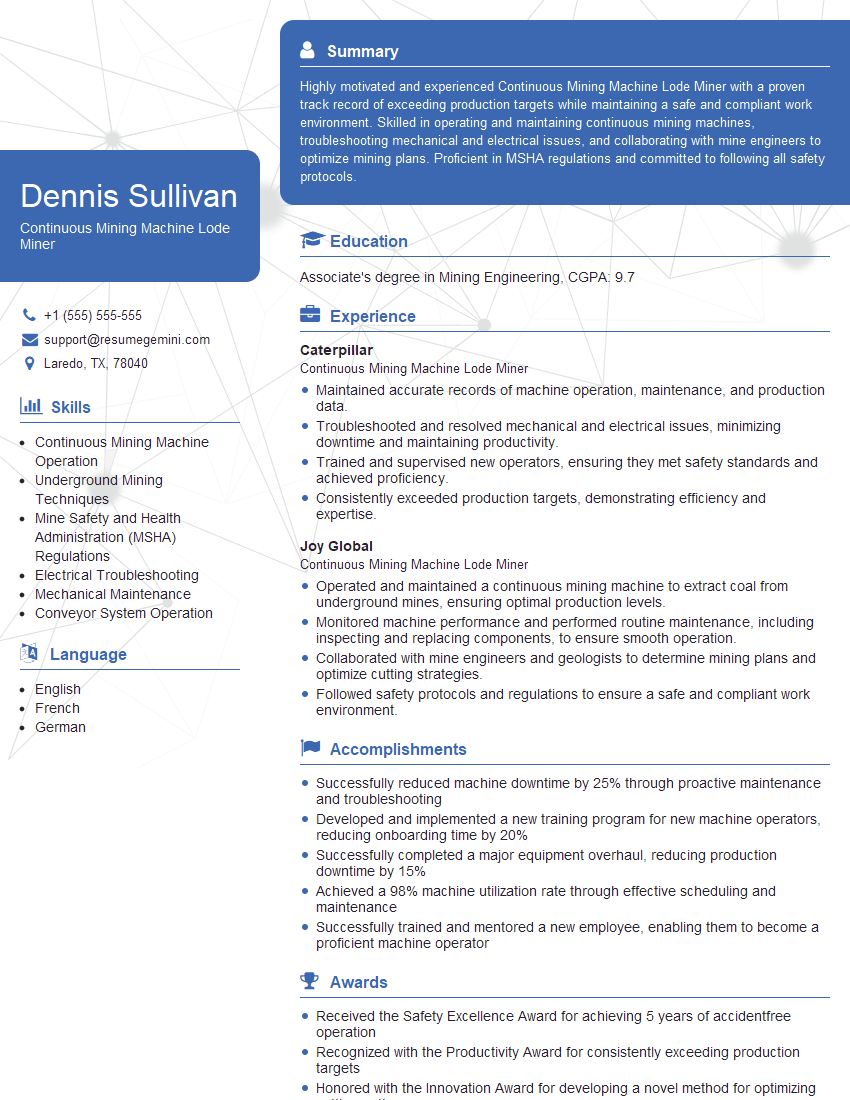

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Mining Machine Lode Miner

1. How would you adjust the cutterhead to minimize the amount of spillage produced by the continuous mining machine?

- Set the cutterhead angle to match the face conditions.

- Adjust the cutterhead speed and depth of cut to optimize material flow.

- Use water sprays to reduce dust and improve conveyor efficiency.

- Regularly inspect and maintain the cutting tools to ensure optimal performance.

- Monitor the material flow and make adjustments as needed to prevent blockages.

2. Explain how you would troubleshoot and resolve a hydraulic system leak on a continuous mining machine.

Identifying the Source of the Leak

- Inspect the hydraulic lines, fittings, and seals for any visible leaks.

- Use a stethoscope to listen for unusual noises that may indicate a leak.

- Check the hydraulic fluid level and pressure to identify any anomalies.

Repairing the Leak

- Replace damaged hydraulic lines, fittings, or seals.

- Tighten loose connections or adjust hydraulic pressure as needed.

- Use leak-detecting dye to locate and identify the exact source of the leak.

- Follow proper safety procedures and manufacturer guidelines when handling hydraulic systems.

3. How do you maintain the electrical systems on a continuous mining machine to ensure safe and reliable operation?

- Regularly inspect electrical components for damage, corrosion, or loose connections.

- Test and calibrate electrical systems as per manufacturer’s recommendations.

- Replace faulty electrical components promptly to prevent accidents or downtime.

- Follow proper lockout/tagout procedures to ensure safety during maintenance.

- Maintain proper ventilation and grounding to prevent electrical hazards.

4. Describe the procedures you follow to ensure the safe and efficient operation of a continuous mining machine.

- Conduct pre-shift inspections to check machine functionality and safety features.

- Operate the machine within designated parameters and monitor performance indicators.

- Identify and address any potential hazards or unsafe conditions immediately.

- Follow proper ventilation and dust control measures to maintain a safe work environment.

- Communicate effectively with other operators and personnel to coordinate mining activities.

5. How do you optimize the performance of a continuous mining machine to achieve maximum production levels?

- Monitor cutting head performance and adjust settings to maximize material flow.

- Optimize conveyor speed and tension to prevent spillage and ensure efficient material handling.

- Use automated controls to maintain consistent cutting depth and minimize operator fatigue.

- Regularly calibrate sensors and instruments to ensure accuracy and optimize performance.

- Implement predictive maintenance strategies to prevent breakdowns and reduce downtime.

6. Explain how you would interpret data from the machine’s sensors to identify potential maintenance issues and take preventative actions.

- Monitor temperature, vibration, and pressure sensors to identify abnormal readings.

- Analyze data trends to predict potential failures and schedule maintenance accordingly.

- Use diagnostic tools to pinpoint the source of problems and plan repairs.

- Implement condition-based maintenance strategies to optimize machine performance and longevity.

- Communicate maintenance needs to supervisors and collaborate on repair scheduling.

7. How do you work effectively in a team environment, especially when coordinating with other operators and support staff?

- Communicate clearly and effectively to convey information and coordinate activities.

- Cooperate with other operators to ensure smooth machine operation and material flow.

- Follow instructions from supervisors and respond promptly to requests for assistance.

- Participate in team meetings and contribute ideas for process improvement.

- Maintain a positive and supportive work environment for all team members.

8. How do you stay up-to-date on the latest mining technologies, best practices, and safety regulations?

- Attend industry conferences and training sessions to learn about new technologies and advancements.

- Read technical journals and publications to stay informed about industry trends.

- Participate in online forums and discussion groups to connect with other mining professionals.

- Follow industry leaders and experts on social media to stay abreast of thought leadership.

- Collaborate with vendors and manufacturers to gain knowledge about cutting-edge equipment and solutions.

9. What are the key safety considerations for operating a continuous mining machine, and how do you ensure compliance with these guidelines?

- Wear appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and gloves.

- Follow prescribed operating procedures and never override safety mechanisms.

- Identify and mitigate potential hazards such as electrical hazards, moving machinery, and falling objects.

- Maintain a safe working environment by keeping walkways clear and equipment well-maintained.

- Participate in regular safety training and follow established emergency protocols.

10. Describe a challenging situation you faced while operating a continuous mining machine, and how you overcame it.

- Experienced a hydraulic system failure and had to troubleshoot and repair the issue to minimize downtime.

- Encountered difficult cutting conditions and had to adjust machine settings and cutting strategy to maintain production.

- Faced coordination challenges with other operators and support staff and had to communicate effectively to resolve issues and ensure smooth operation.

- Identified a potential safety hazard and took immediate action to mitigate the risk and prevent an incident.

- Successfully implemented a new maintenance procedure that improved machine reliability and reduced operating costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Mining Machine Lode Miner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Mining Machine Lode Miner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Continuous Mining Machine Lode Miners are responsible for the safe and efficient operation of continuous mining machines in underground mining environments. Their primary duties include:

1. Machine Operation

Operate and maintain continuous mining machines, ensuring optimal performance and production levels.

- Monitor machine performance, identify potential issues, and take corrective actions.

- Maintain and repair machines according to manufacturer’s specifications.

2. Safety Management

Adhere to established safety protocols and procedures to ensure the well-being of self and others.

- Inspect equipment and work areas for potential hazards, and implement appropriate control measures.

- Follow emergency response plans and procedures in case of accidents or incidents.

3. Production Optimization

Maximize production efficiency by optimizing machine utilization and minimizing downtime.

- Plan and execute mining operations, taking into account geological conditions and production targets.

- Monitor production data and identify areas for improvement.

4. Team Collaboration

Work effectively as part of a mining team, collaborating with other miners, supervisors, and engineers.

- Communicate effectively with team members to ensure smooth operation.

- Support other miners and assist with training and development.

Interview Tips

To ace your interview for a Continuous Mining Machine Lode Miner position, consider the following preparation tips:

1. Research the Company and Industry

Familiarize yourself with the mining company’s history, operations, and safety record. Research industry trends and best practices to demonstrate your knowledge and interest.

2. Highlight Your Experience and Skills

Emphasize your previous experience operating continuous mining machines and managing underground mining operations. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency.

3. Prepare for Technical Questions

Expect technical questions related to continuous mining machine operation, safety protocols, and production optimization techniques. Review relevant materials and practice answering questions in a clear and concise manner.

4. Demonstrate Your Safety Consciousness

Mining is an inherently hazardous industry. Highlight your commitment to safety by describing your understanding of safety regulations, your experience identifying and mitigating risks, and your willingness to follow established protocols.

5. Showcase Your Teamwork and Communication Skills

Mining operations require effective teamwork and communication. Share examples of your collaboration with other miners, supervisors, and engineers, emphasizing your ability to work as part of a cohesive team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Continuous Mining Machine Lode Miner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Continuous Mining Machine Lode Miner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.