Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Continuous Naphtha Treating Plant Recoverer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

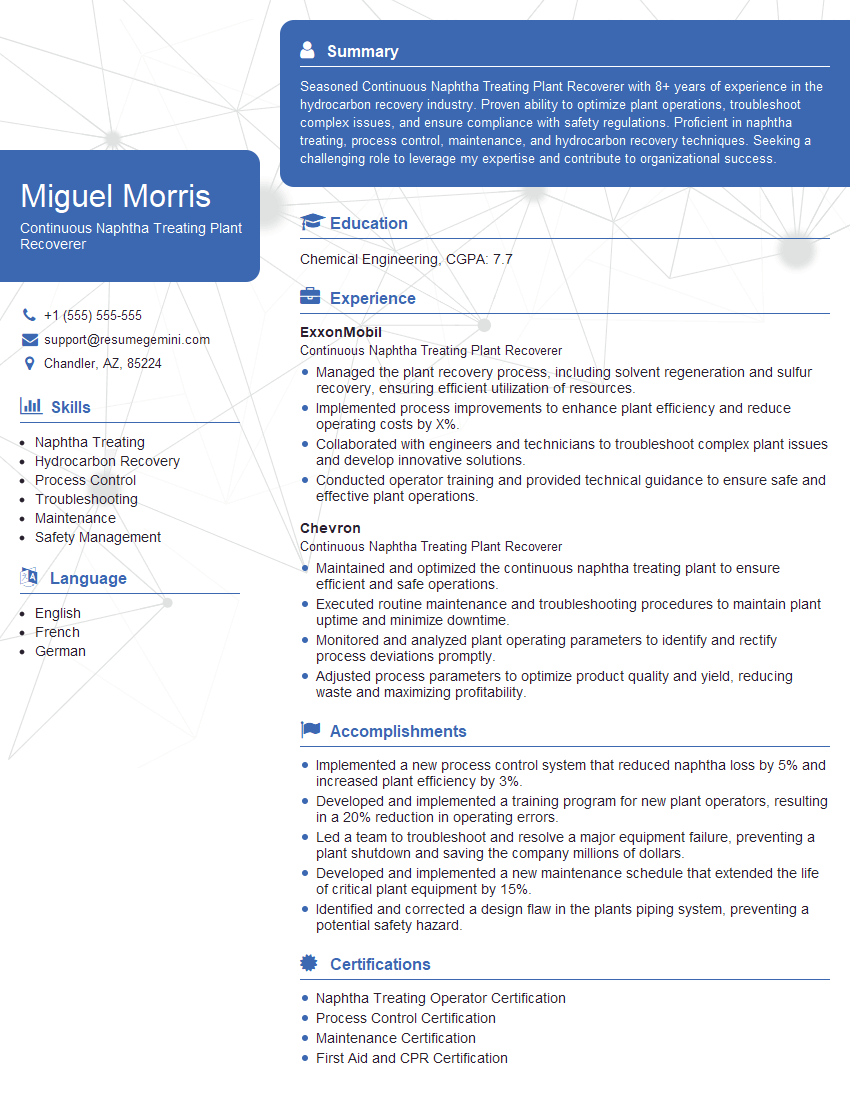

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Naphtha Treating Plant Recoverer

1. What are the key performance indicators (KPIs) for a Continuous Naphtha Treating Plant Recoverer?

- Naphtha recovery efficiency

- Hydrotreater feed quality

- Energy consumption

- Plant availability

- Maintenance costs

2. Describe the process flow of a Continuous Naphtha Treating Plant.

Naphtha Feed Pretreatment

- Desalting: Removing salts and impurities from the naphtha feed.

- Dehydration: Removing water from the naphtha feed.

Naphtha Treating

- Catalytic Hydrotreating: Converting sulfur compounds, nitrogen compounds, and olefins in the naphtha into hydrogen sulfide, ammonia, and paraffins.

- Guard Bed Protection: Protecting the hydrotreating catalyst from contaminants such as chlorides and heavy metals.

- Amine Treating: Removing hydrogen sulfide from the treated naphtha.

Naphtha Recovery

- Stabilization: Removing light ends from the treated naphtha.

- Fractionation: Separating the treated naphtha into different components based on their boiling points.

3. What are the common causes of naphtha loss in a Continuous Naphtha Treating Plant?

- Inadequate feed pretreatment

- Catalyst deactivation

- Amine degradation

- Equipment malfunctions

- Process upsets

4. How do you optimize the operation of a Continuous Naphtha Treating Plant for maximum naphtha recovery?

- Monitor KPIs closely and make adjustments as needed.

- Ensure proper feed pretreatment.

- Maintain the hydrotreating catalyst activity.

- Keep the amine treating system clean and efficient.

- Regularly inspect and maintain equipment.

- Troubleshoot and resolve process upsets quickly.

5. What are the safety precautions that must be taken when working in a Continuous Naphtha Treating Plant?

- Wear appropriate personal protective equipment (PPE).

- Follow established safety procedures.

- Be aware of potential hazards such as toxic gases, flammable liquids, and high-pressure equipment.

- Report any unsafe conditions or practices immediately.

- Receive regular safety training.

6. How do you handle process upsets in a Continuous Naphtha Treating Plant?

- Identify the root cause of the upset.

- Implement corrective actions to resolve the upset.

- Monitor the situation closely until the plant is stabilized.

- Document the upset and the corrective actions taken.

- Learn from the upset to prevent future occurrences.

7. What are the latest advancements in Continuous Naphtha Treating Plant technology?

- Advanced catalyst systems

- Improved amine treating solvents

- Online monitoring and control systems

- Process optimization software

- Artificial intelligence (AI) applications

8. How do you stay up-to-date with the latest developments in Continuous Naphtha Treating Plant technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Network with other professionals in the field.

- Participate in continuing education programs.

9. What are the challenges and opportunities in the Continuous Naphtha Treating Plant industry?

Challenges

- Increasing demand for cleaner fuels.

- Rising energy costs.

- Environmental regulations.

- Competition from other fuel sources.

Opportunities

- Developing more efficient and environmentally friendly technologies.

- Expanding into new markets.

- Collaborating with other industries to find new applications for naphtha treats.

10. Why are you interested in working as a Continuous Naphtha Treating Plant Recoverer?

I am interested in working as a Continuous Naphtha Treating Plant Recoverer because I am passionate about working in the refining industry. I am particularly interested in the challenges and opportunities presented by the Continuous Naphtha Treating Plant process. I am confident that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Naphtha Treating Plant Recoverer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Naphtha Treating Plant Recoverer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Continuous Naphtha Treating Plant Recoverer is responsible for the safe and efficient operation of the continuous naphtha treating plant. The primary objective of this role is to ensure that the naphtha meets the required specifications and is recovered efficiently.

1. Plant Operations

The job responsibilities include:

- Monitoring and controlling the process parameters, such as feed rate, temperature, pressure, and flow rates, to ensure that the plant is operating within the specified limits.

- Responding to process upsets and taking corrective actions to minimize downtime.

- Performing routine maintenance and troubleshooting on the plant equipment.

2. Product Quality

The job responsibilities include:

- Monitoring the product quality to ensure that it meets the required specifications.

- Investigating and resolving any quality issues that may arise.

- Developing and implementing quality control procedures.

3. Safety and Environment

The job responsibilities include:

- Following all safety procedures and regulations.

- Identifying and assessing potential hazards in the workplace.

- Implementing measures to prevent accidents and injuries.

4. Other Responsibilities

The job responsibilities may also include:

- Training and supervising new operators.

- Participating in plant improvement projects.

- Documenting plant operations and maintenance activities.

Interview Tips

Preparing for an interview for the position of Continuous Naphtha Treating Plant Recoverer can be overwhelming. Here are a few tips to help you ace the interview:

1. Research the Company and the Role

Take the time to learn about the company’s history, mission, and values. Research the specific role you are applying for and familiarize yourself with the key responsibilities and qualifications.

- Visit the company’s website and social media pages to gather information about their culture and recent developments.

- Read industry publications and articles to stay updated on the latest trends and technologies in the field.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience that are relevant to the role. Quantify your accomplishments whenever possible to demonstrate your impact.

- Prepare examples of projects or initiatives where you successfully managed process operations, ensured product quality, or implemented safety measures.

- Discuss your experience with specific equipment or technologies used in continuous naphtha treating plants.

3. Demonstrate Your Problem-Solving Abilities

Interviewers often ask questions to assess your problem-solving abilities. Share examples of how you have identified and resolved issues in a plant environment.

- Describe a situation where you encountered an unexpected process upset and the steps you took to troubleshoot and resolve it.

- Explain how you approach problem-solving and the tools or techniques you use.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the opportunity. Prepare questions that show you have thoroughly researched the company and the role.

- Inquire about the company’s growth plans or industry outlook.

- Ask about the specific challenges or opportunities the plant is currently facing.

- Seek clarification on any aspects of the role or the company culture that you are curious about.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Continuous Naphtha Treating Plant Recoverer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!