Feeling lost in a sea of interview questions? Landed that dream interview for Continuous Pickling Line Pickler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Continuous Pickling Line Pickler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

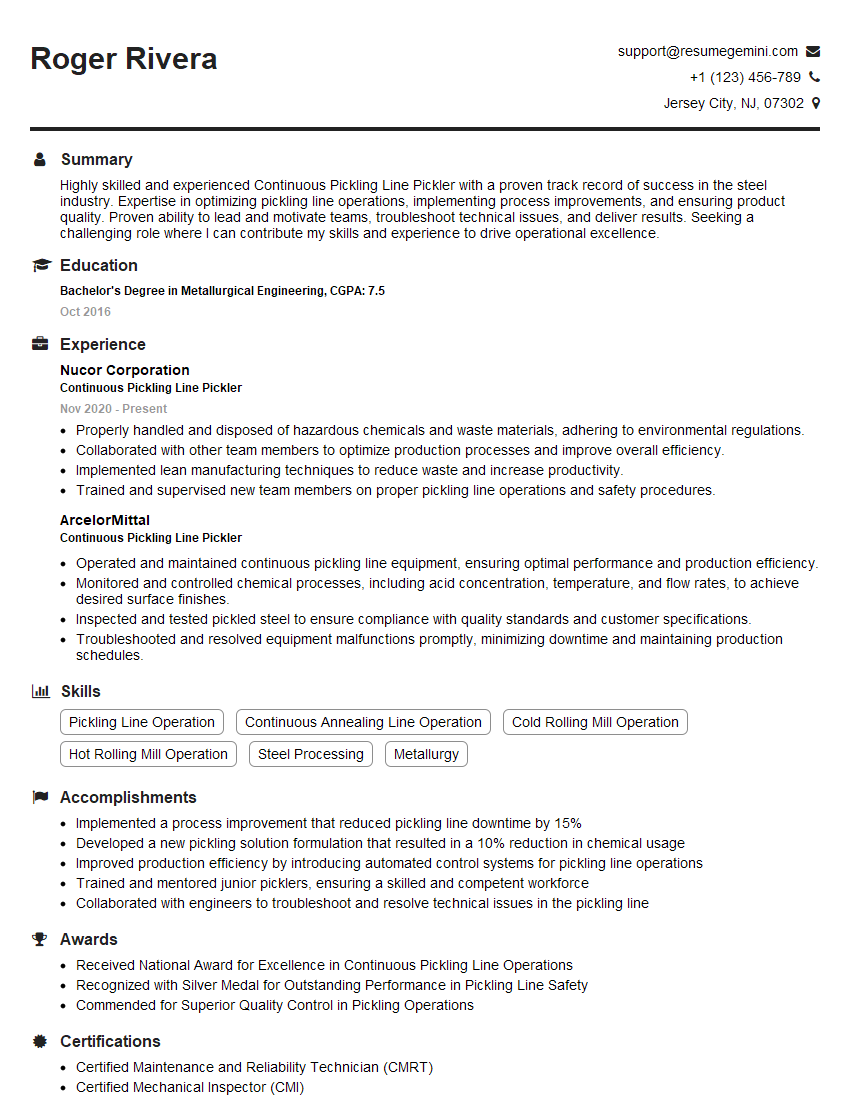

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Pickling Line Pickler

1. Describe the key responsibilities of a Continuous Pickling Line Pickler?

As a Continuous Pickling Line Pickler, my primary responsibilities include:

- Operating and monitoring the continuous pickling line to ensure optimal efficiency and production output.

- Maintaining and troubleshooting the pickling line equipment, including acid tanks, rollers, and control systems.

- Inspecting pickled steel to ensure it meets quality standards and specifications.

- Performing regular maintenance and cleaning procedures to maintain the pickling line in peak operating condition.

- Adhering to safety protocols and following established operating procedures to prevent accidents and minimize risks.

2. Explain the chemical process involved in steel pickling?

Acid Bath Reaction

- The steel strip is immersed in an acidic solution, typically hydrochloric or sulfuric acid.

- The acid reacts with the iron oxide layer (scale) on the steel surface, dissolving it and forming soluble iron salts.

Rinsing and Neutralization

- After pickling, the steel is rinsed with water to remove residual acid and iron salts.

- A neutralizing solution, such as sodium carbonate or lime, is applied to neutralize any remaining acid and prevent corrosion.

Drying

- The pickled steel is dried using hot air or gas to remove moisture and prevent flash rust.

- The drying process is critical to maintain the steel’s surface quality and prevent subsequent corrosion.

3. What are the different types of pickling lines and their respective applications?

- Batch Pickling Lines: Used for small batches of steel or specialty applications. The steel is immersed in acid tanks for a specific duration and then rinsed and dried.

- Continuous Pickling Lines: Highly automated and high-volume lines designed for continuous processing of steel strip. The strip is passed through a series of acid tanks, rinses, and dryers.

- Hydrochloric Acid Pickling Lines: Utilize hydrochloric acid as the pickling agent, resulting in high pickling rates and a bright surface finish.

- Sulfuric Acid Pickling Lines: Employ sulfuric acid, which is less corrosive and generates less hydrogen embrittlement but may require longer pickling times.

4. Describe the quality control procedures involved in pickling steel?

- Visual Inspection: Examining the pickled steel for any surface defects, such as scratches, pits, or stains.

- Acid Concentration Monitoring: Regularly measuring the acid concentration in the pickling tanks to ensure optimal pickling conditions.

- Thickness Measurement: Using ultrasonic or eddy current techniques to verify the steel strip’s thickness after pickling.

- Metallurgical Testing: Conducting tests to assess the microstructure and mechanical properties of the pickled steel, including hardness, tensile strength, and elongation.

5. How do you handle equipment malfunctions or breakdowns on the pickling line?

- Identify the Issue: Quickly determine the nature and location of the malfunction or breakdown.

- Isolate the Problem: Take necessary steps to isolate the affected area and prevent further damage to the equipment or steel.

- Troubleshooting and Repair: Use technical knowledge and experience to troubleshoot the problem and implement appropriate repairs.

- Coordination with Maintenance: Collaborate with maintenance personnel if the repair requires specialized expertise or equipment.

- Documentation: Record the details of the malfunction, troubleshooting process, and repair actions for future reference.

6. What safety precautions and personal protective equipment (PPE) are essential for pickling line operations?

- Acid-Resistant Clothing: Wearing appropriate clothing, gloves, and boots made of acid-resistant materials to prevent chemical burns.

- Respiratory Protection: Using respirators to protect against acid fumes and other airborne contaminants.

- Eye Protection: Wearing safety glasses or goggles to prevent acid splashes or other eye injuries.

- Emergency Response Training: Being trained and equipped to respond effectively to chemical spills or other emergencies.

- Adherence to Safety Protocols: Following established safety protocols, such as avoiding contact with acid, using proper handling techniques, and maintaining a clean work area.

7. How do you ensure the environmental compliance of the pickling line operations?

- Acid Neutralization: Implementing systems to neutralize spent acid before discharging it to wastewater treatment facilities.

- Sludge Management: Proper disposal or recycling of sludge generated during the pickling process.

- Air Pollution Control: Utilizing scrubbers or other devices to control and minimize air emissions from the pickling line.

- Compliance Monitoring: Regularly monitoring and recording environmental parameters, such as pH levels and emissions, to ensure adherence to regulations.

- Continuous Improvement: Seeking opportunities to enhance environmental performance and reduce the ecological footprint of the pickling line.

8. How do you stay updated with the latest advancements and best practices in pickling technology?

- Industry Conferences and Exhibitions: Attending industry events to learn about new technologies and exchange knowledge with peers.

- Technical Journals and Publications: Regularly reading relevant journals and articles to stay informed about research and advancements in pickling.

- Manufacturer Training: Participating in training sessions offered by equipment manufacturers to enhance technical skills and knowledge.

- Online Resources: Utilizing industry websites, webinars, and online forums to access up-to-date information and best practices.

- Collaboration with Experts: Networking with engineers, metallurgists, and other professionals in the field to share knowledge and exchange ideas.

9. How do you prioritize tasks and manage multiple responsibilities in a fast-paced production environment?

- Prioritization Matrix: Using a prioritization tool, such as the Eisenhower Matrix, to categorize tasks based on urgency and importance.

- Time Management Techniques: Employing techniques like the Pomodoro Technique or time blocking to optimize time allocation.

- Delegation: Delegating tasks to team members with appropriate skills and experience to ensure efficient task completion.

- Communication and Coordination: Communicating effectively with colleagues and supervisors to coordinate tasks and avoid overlaps or bottlenecks.

- Adaptability and Flexibility: Being adaptable and flexible to adjust priorities and schedules as production demands change.

10. Describe a situation where you successfully resolved a complex issue on the pickling line.

In one instance, the pickling line experienced a sudden drop in acid concentration, resulting in insufficient scale removal and poor surface quality of the steel.

I promptly analyzed the situation and identified a malfunction in the acid replenishment system. I coordinated with the maintenance team to diagnose and repair the issue, ensuring the smooth flow of acid into the pickling tanks.

Additionally, I adjusted the line speed and rinsing parameters to compensate for the lower acid concentration, maintaining optimal pickling results.

As a result, the pickling line regained its efficiency, and the steel surface quality met the required specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Pickling Line Pickler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Pickling Line Pickler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Continuous Pickling Line Picklers assume a crucial role in ensuring the smooth functioning of the pickling line, a critical process in steel production. Their primary responsibilities include:

1. Line Operations

Manage all aspects of the pickling line operations, including equipment setup, process control, and quality monitoring.

- Operate and monitor equipment such as acid tanks, rinse tanks, and conveyor systems.

- Adjust process parameters (e.g., acid concentration, temperature) to achieve optimal pickling results.

2. Quality Assurance

Conduct regular inspections and testing to ensure the pickled steel meets required specifications.

- Inspect pickled steel for surface defects, cleanliness, and other quality attributes.

- Perform laboratory tests to analyze steel samples and ensure compliance with standards.

3. Maintenance and Troubleshooting

Perform routine maintenance tasks and troubleshoot any equipment malfunctions or process issues.

- Clean and maintain equipment to ensure optimal performance.

- Identify and resolve problems related to equipment, process parameters, or raw materials.

4. Safety and Compliance

Maintain a safe and compliant work environment.

- Follow established safety protocols and procedures.

- Handle hazardous materials (e.g., acids) safely and responsibly.

Interview Tips

Preparing thoroughly for an interview can significantly boost your chances of success. Consider the following tips:

1. Research the Position and Company

Familiarize yourself with the specific responsibilities of the Continuous Pickling Line Pickler role and the company’s overall operations. This will help you understand the company’s expectations and demonstrate your interest.

2. Practice Answering Common Interview Questions

Anticipate questions related to your experience, skills, and qualifications. Prepare thoughtful and concise answers that highlight your strengths and how they align with the job requirements. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Your Technical Expertise

Emphasize your proficiency in pickling line operations, quality assurance techniques, and maintenance procedures. Provide specific examples of your contributions and achievements in previous roles.

4. Showcase Your Problem-Solving Abilities

Interviewers often seek candidates with strong problem-solving skills. Share instances where you successfully identified and resolved complex issues related to equipment malfunctions, process inefficiencies, or quality deviations.

5. Prepare Questions to Ask

Asking well-informed questions demonstrates your enthusiasm and engagement. Prepare thoughtful questions about the company’s culture, growth opportunities, and commitment to safety and sustainability.

Next Step:

Now that you’re armed with the knowledge of Continuous Pickling Line Pickler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Continuous Pickling Line Pickler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini