Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Continuous Process Rotary Drum Tanner interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Continuous Process Rotary Drum Tanner so you can tailor your answers to impress potential employers.

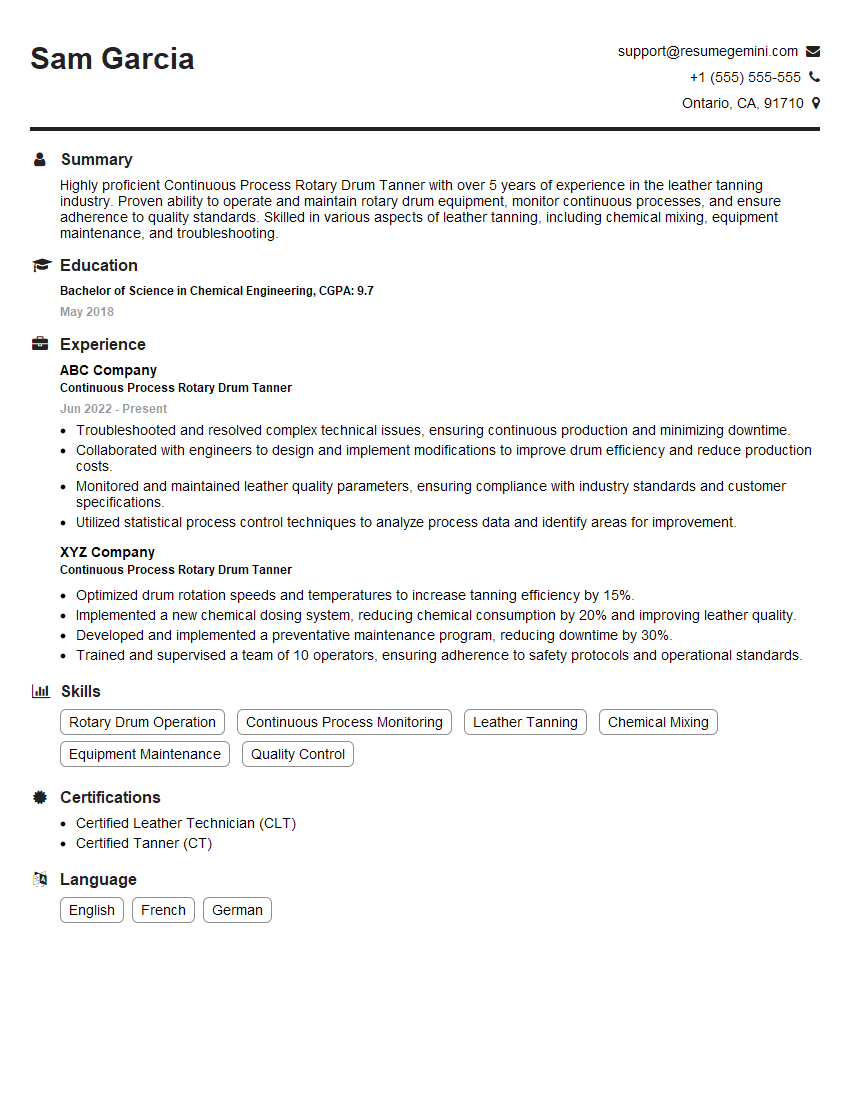

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Continuous Process Rotary Drum Tanner

1. Describe the key components and their functions in a Continuous Process Rotary Drum Tanner?

- Hide loading drum: Tumbling drums loaded with hides to be tanned.

- Chemical bath tanks: Holding tanks containing tanning solutions.

- Conveyor system: Moves hides through the tanning process.

- Control system: Monitors and adjusts process parameters.

- Wastewater treatment system: Treats wastewater generated from the process.

2. Explain the different stages involved in the continuous process rotary drum tanning method?

- Loading: Hides are loaded into the hide loading drum.

- Tanning: Hides are submerged in tanning solutions in the chemical bath tanks.

- Washing: Hides are rinsed with water to remove excess tanning solution.

- Drying: Hides are dried to remove excess moisture.

- Grading: Hides are inspected and graded based on quality.

3. What factors influence the quality of tanned hides produced using a Continuous Process Rotary Drum Tanner?

- Hide quality: Condition and characteristics of the raw hide.

- Tanning process parameters: Temperature, pH, and concentration of tanning solutions.

- Equipment maintenance: Regular maintenance of machinery to ensure optimal performance.

- Operator skill: Expertise in operating the equipment and monitoring the process.

4. What are the safety precautions that need to be taken when operating a Continuous Process Rotary Drum Tanner?

- Wear appropriate personal protective equipment (PPE): Gloves, goggles, and protective clothing.

- Follow operating procedures: Adhere to established protocols to avoid accidents.

- Be aware of potential hazards: Identify and mitigate risks such as slips, falls, and chemical exposure.

- Ensure proper ventilation: Maintain adequate airflow to remove fumes and odors.

5. How do you troubleshoot common problems that may occur during the continuous process rotary drum tanning operation?

- Hide damage: Inspect hides for cuts or tears and adjust process parameters if necessary.

- Uneven tanning: Check chemical bath concentrations, pH, and mixing efficiency.

- Excessive water consumption: Monitor rinsing process and adjust water flow rates.

- Equipment malfunction: Identify the source of the problem and contact maintenance personnel if required.

6. Describe the role of temperature control in the continuous process rotary drum tanning method?

Temperature control is crucial for ensuring optimal tanning results and preventing damage to hides. Tanning solutions operate within specific temperature ranges, and deviation from these ranges can affect the rate and quality of tanning.

7. How do you calculate the amount of tanning solution required for a given batch of hides?

To calculate the required tanning solution, determine the weight of the hides and the target bath ratio (e.g., mL of solution per kg of hide). Multiply the hide weight by the bath ratio to obtain the volume of tanning solution.

8. What is the importance of proper wastewater treatment in the continuous process rotary drum tanning operation?

Proper wastewater treatment removes harmful chemicals and pollutants generated during the tanning process. It complies with environmental regulations and protects the ecosystem from contamination.

9. How do you monitor the performance of a Continuous Process Rotary Drum Tanner?

- Hide quality: Evaluate tanned hides for uniformity, color, and texture.

- Process parameters: Monitor temperature, pH, and solution concentration.

- Equipment efficiency: Track production rates, downtime, and maintenance frequency.

- Wastewater quality: Ensure compliance with environmental standards by monitoring effluent characteristics.

10. What are the latest advancements in Continuous Process Rotary Drum Tanning technology?

- Automated process control: Advanced systems optimize tanning parameters and reduce operator intervention.

- Improved wastewater treatment: Innovative technologies enhance wastewater quality and reduce environmental impact.

- Sustainable tanning solutions: Environmentally friendly tanning agents and processes minimize chemical usage and waste generation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Continuous Process Rotary Drum Tanner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Continuous Process Rotary Drum Tanner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Continuous Process Rotary Drum Tanner is responsible for operating a rotary drum tanner, which is a machine used to tan animal hides. The key job responsibilities include:

1. Operating the Rotary Drum Tanner

The tanner operates the rotary drum tanner by loading hides into the drum, adding chemicals and water, and setting the temperature and rotation speed. The tanner must monitor the tanning process and make adjustments as needed.

- Loading hides into the drum

- Adding chemicals and water

- Setting the temperature and rotation speed

- Monitoring the tanning process

- Making adjustments as needed

2. Maintaining the Rotary Drum Tanner

The tanner is responsible for maintaining the rotary drum tanner. This includes cleaning the drum, inspecting the equipment, and making repairs as needed.

- Cleaning the drum

- Inspecting the equipment

- Making repairs as needed

3. Quality Control

The tanner must ensure that the hides are tanned to the correct specifications. This includes checking the color, feel, and texture of the hides.

- Checking the color, feel, and texture of the hides

- Making adjustments to the tanning process as needed

4. Safety

The tanner must follow all safety procedures when operating the rotary drum tanner. This includes wearing protective clothing and equipment, and following the manufacturer’s instructions.

- Wearing protective clothing and equipment

- Following the manufacturer’s instructions

- Reporting any safety hazards to the supervisor

Interview Tips

Here are some interview tips to help you ace the interview for a Continuous Process Rotary Drum Tanner position:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you’re applying for. This will show the interviewer that you’re interested in the job and that you’ve taken the time to learn about the company. It will also help you to answer questions about the company, the position, and why you’re the best candidate for the job.

- Visit the company’s website

- Read the job description

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions so that you can deliver them confidently and concisely.

- Write down your answers to common interview questions

- Practice your answers out loud

- Get feedback from a friend or family member

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure that your clothes are clean and pressed, and that you’re well-groomed.

4. Be enthusiastic and positive

The interviewer wants to see that you’re enthusiastic about the job and that you’re excited to work for the company. Be positive and upbeat during your interview, and be sure to highlight your skills and experience.

5. Ask questions

Asking questions at the end of the interview shows that you’re interested in the job and that you’re engaged in the conversation. It also gives you an opportunity to learn more about the company and the position. Be sure to ask thoughtful questions that are relevant to the job.

- What are the biggest challenges facing the company?

- What are the opportunities for growth within the company?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Continuous Process Rotary Drum Tanner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!