Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Control Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

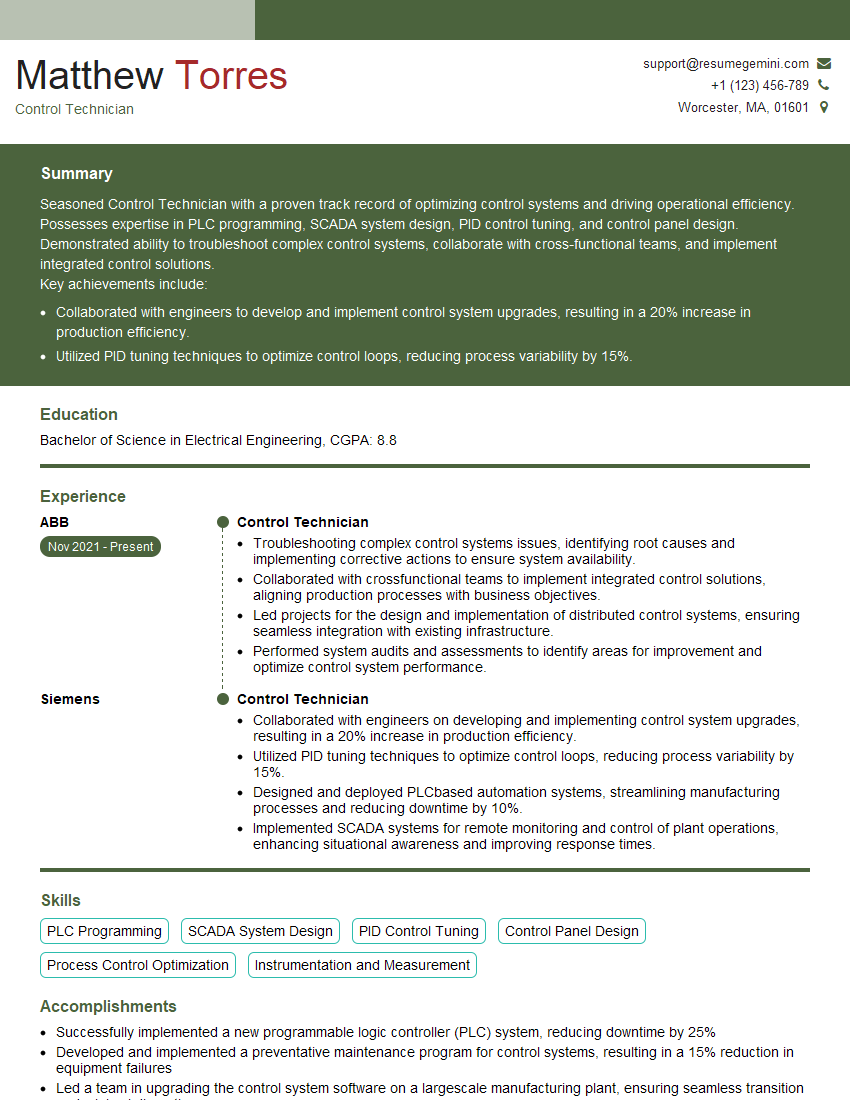

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Control Technician

1. Explain the role of a proportional-integral-derivative (PID) controller in an industrial control system.

- PID controller is used to control the output of a system based on the error between the desired output and the actual output.

- The PID controller calculates the error and adjusts the output to minimize the error.

- The proportional term adjusts the output based on the current error, the integral term adjusts the output based on the accumulated error over time, and the derivative term adjusts the output based on the rate of change of the error.

2. Describe the different types of control valves used in industrial applications.

Globe Valve

- Globe valves are used to regulate the flow of fluid in a pipeline.

- They have a spherical or conical plug that moves up and down to control the flow.

Gate Valve

- Gate valves are used to isolate a section of a pipeline.

- They have a gate that slides up and down to open or close the valve.

Ball Valve

- Ball valves are used to control the flow of fluid in a pipeline.

- They have a ball that rotates to open or close the valve.

Butterfly Valve

- Butterfly valves are used to control the flow of fluid in a pipeline.

- They have a disc that rotates to open or close the valve.

Diaphragm Valve

- Diaphragm valves are used to control the flow of corrosive or abrasive fluids.

- They have a diaphragm that separates the fluid from the valve body.

3. Explain the purpose and operation of a programmable logic controller (PLC).

- PLCs are used to automate industrial processes.

- They are programmed to perform specific tasks, such as controlling the flow of fluid in a pipeline, or starting and stopping a motor.

- PLCs are typically programmed using ladder logic, which is a graphical programming language that resembles electrical schematics.

4. Describe the different types of sensors used in industrial control systems.

- Temperature sensors measure the temperature of a medium.

- Pressure sensors measure the pressure of a medium.

- Flow sensors measure the flow rate of a medium.

- Level sensors measure the level of a liquid or solid in a container.

- Proximity sensors detect the presence of an object.

5. Explain the importance of calibration in industrial control systems.

- Calibration ensures that the sensors and other instruments in a control system are accurate and reliable.

- Calibration involves comparing the readings of the sensors and instruments to a known standard.

- Calibration should be performed regularly to ensure that the control system is operating properly.

6. Describe the different types of communication protocols used in industrial control systems.

- Modbus is a widely used protocol for communication between industrial devices.

- Profibus is a protocol that is specifically designed for use in industrial automation systems.

- EtherNet/IP is a protocol that is based on the Ethernet standard and is used in industrial automation systems.

7. Explain the concept of safety instrumented systems (SIS).

- SISs are designed to prevent or mitigate the consequences of hazardous events.

- SISs are typically used in industries where there is a high risk of accidents, such as the chemical industry or the oil and gas industry.

- SISs are designed to be highly reliable and redundant, so that they can continue to operate even if one or more components fail.

8. Describe the different types of industrial networks used in control systems.

- DeviceNet is a network that is specifically designed for use in industrial automation systems.

- Ethernet is a widely used network that can be used in a variety of applications, including industrial automation.

- Wireless networks are becoming increasingly popular in industrial automation systems.

9. Explain the importance of documentation in industrial control systems.

- Documentation is essential for understanding how a control system works.

- Documentation should include information about the system design, the components used, and the programming.

- Documentation should be kept up to date as the system is modified.

10. Describe the different types of maintenance tasks that are performed on industrial control systems.

- Preventive maintenance tasks are performed to prevent problems from occurring.

- Predictive maintenance tasks are performed to identify potential problems before they occur.

- Corrective maintenance tasks are performed to fix problems that have occurred.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Control Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Control Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Control Technicians are responsible for the installation, maintenance, and repair of control systems in various industrial and commercial settings. Their core duties include:

1. Installation and Commissioning

Installing new control systems or upgrading existing ones.

- Verifying system requirements and specifications.

- Wiring and connecting hardware components.

- Configurating and programming control software.

2. Maintenance and Troubleshooting

Maintaining optimal system performance and troubleshooting any issues.

- Performing regular inspections and preventive maintenance tasks.

- Diagnosing and repairing system malfunctions.

- Identifying and resolving software bugs or hardware failures.

3. Process Optimization

Analyzing system data and identifying areas for improvement.

- Monitoring process parameters and performance.

- Recommending and implementing control system enhancements.

- Collaborating with engineers and plant operators to optimize production efficiency.

4. Compliance and Safety

Ensuring compliance with industry regulations and safety standards.

- Adhering to established safety protocols.

- Maintaining appropriate documentation and records.

- Participating in safety training and drills.

Interview Tips

To ace the interview for a Control Technician position, consider these preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, expertise, and ongoing projects.

- Visit the company website and LinkedIn profile.

- Read industry publications and articles to stay up-to-date on the latest trends.

2. Highlight Your Technical Skills

Emphasize your strong understanding of control systems, including PLC programming, SCADA systems, and industrial networks.

- Quantify your experience with specific technologies and programming languages.

- Showcase projects where you have successfully applied your technical knowledge.

3. Demonstrate Your Problem-Solving Abilities

Control Technicians often encounter unexpected challenges. Showcase your ability to identify and resolve issues effectively.

- Share examples of how you have diagnosed and fixed complex control system problems.

- Discuss the troubleshooting techniques and methodologies you use.

4. Emphasize Your Communication and Interpersonal Skills

Control Technicians often work closely with other engineers, operators, and maintenance personnel.

- Highlight your ability to communicate technical concepts clearly and concisely.

- Demonstrate your willingness to collaborate and seek input from others.

5. Prepare for Common Interview Questions

Be prepared to answer questions related to your technical expertise, problem-solving abilities, and work experience.

- Practice answering common interview questions, such as “Tell me about your experience with ladder logic programming” or “How would you troubleshoot a communication issue between a PLC and a SCADA system?”

- Prepare thoughtful and specific responses that showcase your skills and knowledge.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Control Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.