Are you gearing up for an interview for a Controller Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Controller Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

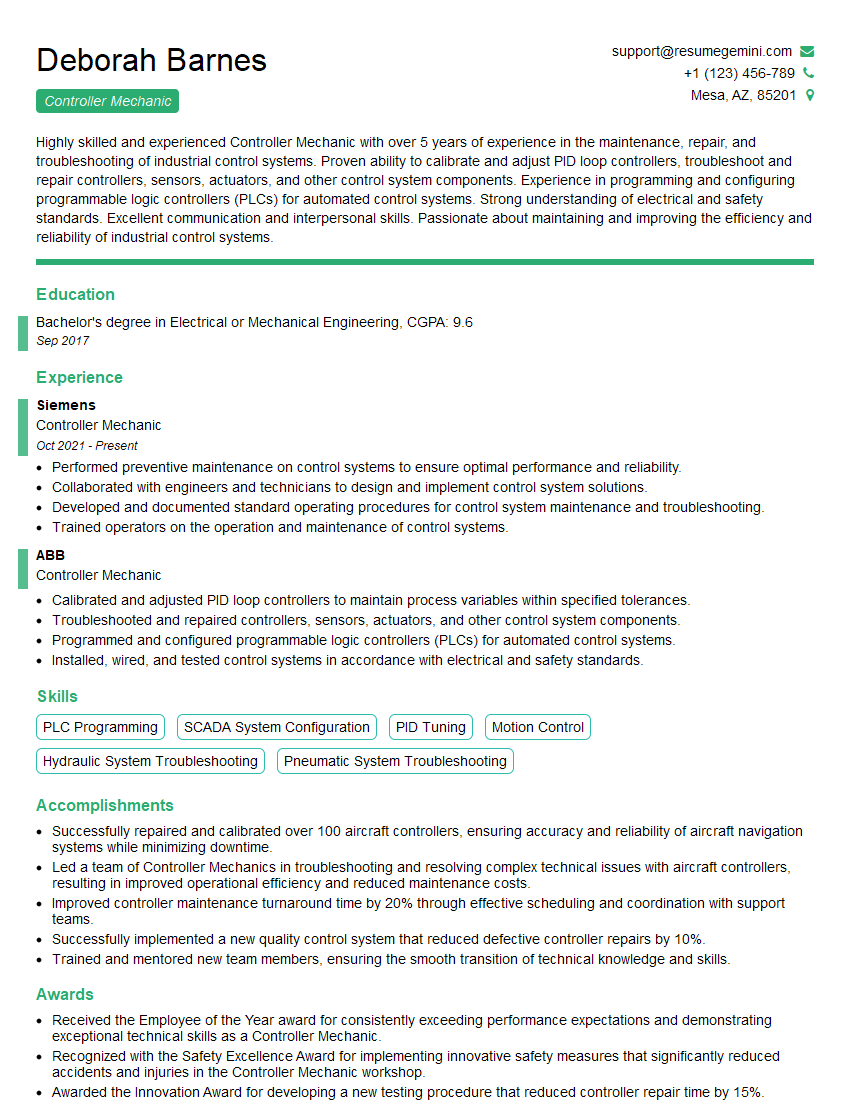

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Controller Mechanic

1. Explain the process of troubleshooting a controller?

- Gather information about the issue, including the symptoms and any error messages.

- Inspect the controller for any obvious damage or loose connections.

- Test the controller using diagnostic software or hardware.

- If the controller fails the test, replace it with a new one.

- If the controller passes the test, continue troubleshooting the system.

2. What are the different types of controllers and their functions?

Programmable Logic Controllers (PLCs)

- Used to control industrial processes and machines.

- Can be programmed to perform a variety of tasks, such as turning on and off motors, reading sensors, and controlling actuators.

Distributed Control Systems (DCSs)

- Used to control large and complex industrial processes, such as oil refineries and power plants.

- Consist of a network of interconnected controllers that communicate with each other to coordinate control actions.

Supervisory Control and Data Acquisition (SCADA) Systems

- Used to monitor and control industrial processes from a remote location.

- Often used in conjunction with PLCs and DCSs to provide a comprehensive control solution.

3. How do you calibrate a controller?

- Connect the controller to a calibration device, such as a multimeter or oscilloscope.

- Follow the calibration procedure outlined in the controller’s manual.

- Adjust the controller’s settings until the output matches the desired value.

- Verify the calibration by testing the controller with a known input.

4. What are the safety precautions that must be taken when working on controllers?

- Always turn off the power to the controller before working on it.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Do not touch any exposed electrical components.

- Be aware of the potential for electrical shock.

- Follow all safety instructions provided in the controller’s manual.

5. What are the most common problems that you have encountered with controllers?

- Controller failure

- Communication problems

- Calibration issues

- Software bugs

- Electrical noise

6. How do you troubleshoot a communication problem between a controller and a field device?

- Check the physical connection between the controller and the field device.

- Verify that the communication settings on the controller and the field device match.

- Use a communication analyzer to test the communication link.

- If the communication link is working properly, check the software on the controller and the field device for any errors.

7. What are the different types of control loops and their applications?

-

Open-loop control

- Does not use feedback to adjust the output.

- Used in simple applications where the output is not critical.

-

Closed-loop control

- Uses feedback to adjust the output.

- Used in applications where the output must be precisely controlled.

8. What is the difference between a PID controller and a PI controller?

-

PID controller

- Uses proportional, integral, and derivative terms to adjust the output.

- Provides more precise control than a PI controller.

-

PI controller

- Uses proportional and integral terms to adjust the output.

- Less complex than a PID controller, but may not provide as precise control.

9. What is the purpose of a deadband in a controller?

- A deadband is a range of input values that do not produce an output from the controller.

- Prevents the controller from responding to small changes in the input value.

- Can be used to reduce noise or to prevent the controller from hunting.

10. What are the advantages of using a digital controller over an analog controller?

- Digital controllers are more accurate than analog controllers.

- Digital controllers are more reliable than analog controllers.

- Digital controllers are more flexible than analog controllers.

- Digital controllers are easier to maintain than analog controllers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Controller Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Controller Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Controller Mechanics play a vital role in maintaining the safety and efficiency of industrial automation systems by servicing and repairing controllers, drives, and other electronic components.

1. Troubleshooting and Repair

They diagnose and resolve malfunctions by analyzing system logs, testing circuits, and replacing or repairing faulty components.

- Conduct thorough inspections and assessments of controllers and drives.

- Use specialized tools and equipment to diagnose electrical and mechanical issues.

2. Maintenance and Calibration

They perform regular maintenance tasks to prevent downtime and ensure optimal performance.

- Clean and inspect controllers, drives, and sensors.

- Calibrate sensors and instruments to maintain accuracy.

3. Installation and Commissioning

They oversee the installation and commissioning of new or upgraded controllers and drives.

- Configure and program controllers according to specifications.

- Conduct testing and verification to ensure proper operation.

4. Documentation and Reporting

They maintain accurate records of all maintenance, repairs, and calibrations.

- Document findings, recommendations, and actions taken.

- Generate reports on system performance and maintenance history.

Interview Tips

Preparing thoroughly for an interview can significantly improve your chances of success. Here are some valuable tips to help you ace the interview for a Controller Mechanic position:

1. Research the Company and Position

Gain a deep understanding of the company’s industry, products, and services. Research the specific role you are applying for, including its responsibilities, requirements, and the company’s expectations.

- Visit the company website and social media platforms.

- Read industry publications and articles related to the company and the role.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful, concise answers. Practice delivering your responses clearly and with confidence. Focus on highlighting your relevant skills and experiences.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments and provide specific examples to demonstrate your impact.

3. Showcase Your Technical Skills

Highlight your technical competencies related to controller mechanics. Emphasize your knowledge of electrical and mechanical systems, troubleshooting techniques, and industry best practices. Provide examples of complex problems you have solved.

- Discuss your experience with specific controller and drive models.

- Share examples of innovative solutions you have implemented to improve system performance.

4. Demonstrate Your Problem-Solving Abilities

Controller Mechanics are often faced with challenging problems. During the interview, demonstrate your logical thinking and problem-solving skills. Explain how you approach diagnosing and resolving technical issues.

- Describe a situation where you successfully identified and fixed a complex malfunction.

- Explain your thought process and the steps you took to resolve the issue.

5. Show Enthusiasm and Motivation

Express your genuine interest in the role and the company. Convey your enthusiasm for controller mechanics and your eagerness to contribute to the team’s success. Demonstrate your motivation to continuously learn and grow.

- Share your knowledge of industry trends and technological advancements.

- Discuss your career goals and how the position aligns with them.

Next Step:

Now that you’re armed with the knowledge of Controller Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Controller Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini