Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Controls Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Controls Technician so you can tailor your answers to impress potential employers.

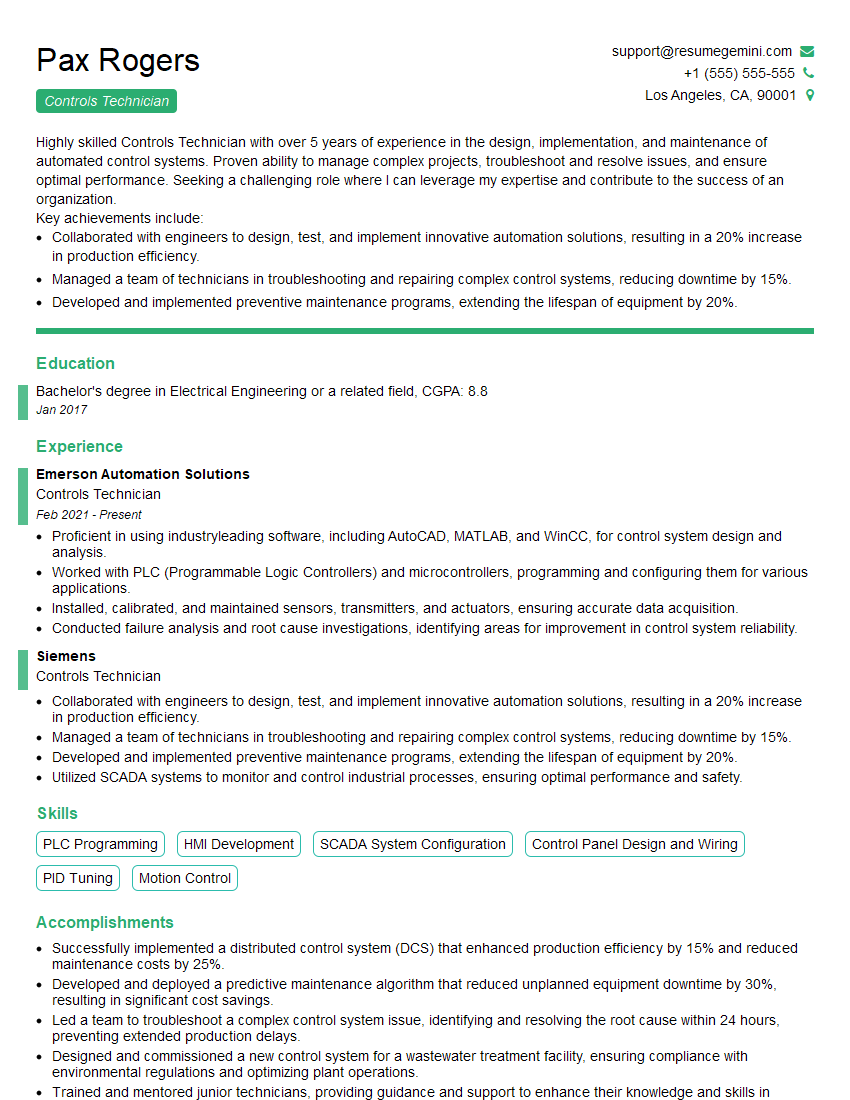

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Controls Technician

1. How would you approach troubleshooting a complex control system that is experiencing intermittent issues?

- Start by gathering as much information as possible about the system, including its configuration, recent changes, and any error messages that have been reported.

- Use diagnostic tools to monitor the system’s performance and identify any potential issues.

- Look for patterns in the intermittent issues, such as whether they occur at specific times or under certain conditions.

- Isolate the problem by testing individual components of the system and replacing any that are faulty.

- Once the problem has been identified, develop a solution and implement it to prevent the issue from recurring.

2. Explain the concept of a feedback loop in a control system and provide an example.

A feedback loop is a closed loop system in which the output of the system is used to control the input. This allows the system to self-correct and maintain a desired state.

Example:

- A thermostat is a common example of a feedback loop. The thermostat measures the temperature in a room and compares it to the desired temperature. If the room temperature is too low, the thermostat sends a signal to the heater to turn on. Once the room temperature reaches the desired temperature, the thermostat sends a signal to the heater to turn off.

3. What are the different types of control systems and what are their advantages and disadvantages?

The two main types of control systems are open-loop and closed-loop systems.

Open-loop systems:

- Advantages: Simple to design and implement, low cost

- Disadvantages: Cannot compensate for disturbances, no feedback

Closed-loop systems:

- Advantages: Can compensate for disturbances, provides feedback

- Disadvantages: More complex to design and implement, higher cost

4. What are the different types of sensors used in control systems and what are their applications?

There are many different types of sensors used in control systems, each with its own specific applications.

Some of the most common types of sensors include:

- Temperature sensors

- Pressure sensors

- Flow sensors

- Position sensors

- Speed sensors

5. What is the difference between proportional, integral, and derivative (PID) control and when is each type of control used?

- Proportional control is used to reduce the error between the desired and actual values. The output of a proportional controller is proportional to the error.

- Integral control is used to eliminate the steady-state error. The output of an integral controller is proportional to the integral of the error.

- Derivative control is used to anticipate changes in the error and to reduce the overshoot. The output of a derivative controller is proportional to the derivative of the error.

6. What are the different types of actuators used in control systems and what are their advantages and disadvantages?

There are many different types of actuators used in control systems, each with its own specific advantages and disadvantages.

Some of the most common types of actuators include:

- Electric actuators: Advantages: High precision, fast response, low maintenance. Disadvantages: High cost, limited force.

- Hydraulic actuators: Advantages: High force, low cost, simple design. Disadvantages: Slow response, requires a hydraulic power source.

- Pneumatic actuators: Advantages: High force, fast response, low cost. Disadvantages: Requires a pneumatic power source, noisy.

7. What is the difference between a PLC and a DCS and when is each type of control system used?

- A PLC (Programmable Logic Controller) is a small, self-contained control system that is used for simple to medium-complexity applications.

- A DCS (Distributed Control System) is a large, complex control system that is used for large-scale applications such as power plants and manufacturing facilities.

8. What are the different types of communication protocols used in control systems and what are their advantages and disadvantages?

There are many different types of communication protocols used in control systems, each with its own specific advantages and disadvantages.

Some of the most common types of communication protocols include:

- Ethernet: Advantages: High speed, low cost, widely supported. Disadvantages: Not suitable for harsh environments.

- Modbus: Advantages: Simple to implement, low cost, widely supported. Disadvantages: Slow speed, limited data capacity.

- CAN bus: Advantages: High speed, robust, suitable for harsh environments. Disadvantages: Complex to implement, high cost.

9. What are the different types of software used in control systems and what are their functions?

There are many different types of software used in control systems, each with its own specific functions.

Some of the most common types of software include:

- SCADA (Supervisory Control and Data Acquisition): Used for monitoring and controlling industrial processes.

- MES (Manufacturing Execution System): Used for managing and controlling manufacturing operations.

- PLC programming software: Used for programming PLCs.

10. What are the different types of standards used in control systems and what are their purposes?

There are many different types of standards used in control systems, each with its own specific purpose.

Some of the most common types of standards include:

- IEC 61131-3: Standard for programmable controllers.

- ISA-88: Standard for batch control systems.

- IEC 62443: Standard for security for industrial automation and control systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Controls Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Controls Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Controls Technician plays a pivotal role in ensuring the seamless operation of automated systems and processes within a wide range of industries.

Their primary responsibilities include:

1. System Maintenance and Troubleshooting

Controls Technicians are responsible for maintaining, inspecting, and resolving issues with various control systems, including Programmable Logic Controllers (PLCs), Distributed Control Systems (DCSs), and Supervisory Control and Data Acquisition (SCADA) systems.

- Identifying and diagnosing faults in systems using tools like voltmeters, oscilloscopes, and diagnostic software.

- Performing scheduled maintenance and calibration to ensure optimal system performance.

- Troubleshooting and resolving hardware and software issues promptly to minimize production downtime.

2. System Installation and Commissioning

Controls Technicians work closely with engineers and project managers to install and commission new control systems.

- Following design specifications and wiring schematics to install control panels, sensors, and actuators.

- Testing and calibrating systems to ensure accuracy and functionality.

- Providing training and documentation to end-users on system operation and maintenance.

3. Process Optimization and Control

Controls Technicians are involved in optimizing and controlling automated processes to enhance efficiency and productivity.

- Analyzing process data and identifying areas for improvement.

- Implementing control strategies using PLCs, DCSs, or SCADA systems to optimize process variables.

- Monitoring and adjusting process parameters to maintain desired outcomes.

4. Team Collaboration and Communication

Controls Technicians work closely with various teams and stakeholders.

- Collaborating with engineers, maintenance personnel, and operators to ensure seamless system integration.

- Communicating effectively with all levels of management to provide updates on system performance and maintenance needs.

- Documenting work procedures, maintenance logs, and other technical reports.

Interview Tips

To ace an interview for a Controls Technician position, follow these tips:

1. Preparation

Become familiar with the specific industry and company where you’re applying.

- Research common control systems used in the industry, such as PLCs, DCSs, and SCADA.

- Review basic electrical and electronic principles, including Ohm’s Law, circuit analysis, and digital logic.

- Practice troubleshooting scenarios using common tools like voltmeters and oscilloscopes.

2. Tailor Your Resume and Cover Letter

Highlight your relevant skills and experience that align with the job responsibilities.

- Quantify your accomplishments using specific metrics, such as systems maintained, processes optimized, or downtime reduced.

- Showcase your ability to work independently and as part of a team.

- Emphasize your problem-solving abilities and attention to detail.

3. Practice Common Interview Questions

Prepare for common interview questions by researching online and practicing with a friend or family member.

- Tell me about a time you troubleshoot a complex system issue.

- How do you stay up-to-date on the latest control technologies?

- What is your experience with PLC programming or DCS configuration?

4. Arrive Prepared

Dress professionally, arrive on time, and bring copies of your resume and cover letter.

- Be prepared to discuss your technical skills, work experience, and career goals.

- Ask thoughtful questions to demonstrate your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Controls Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!