Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Conventional Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

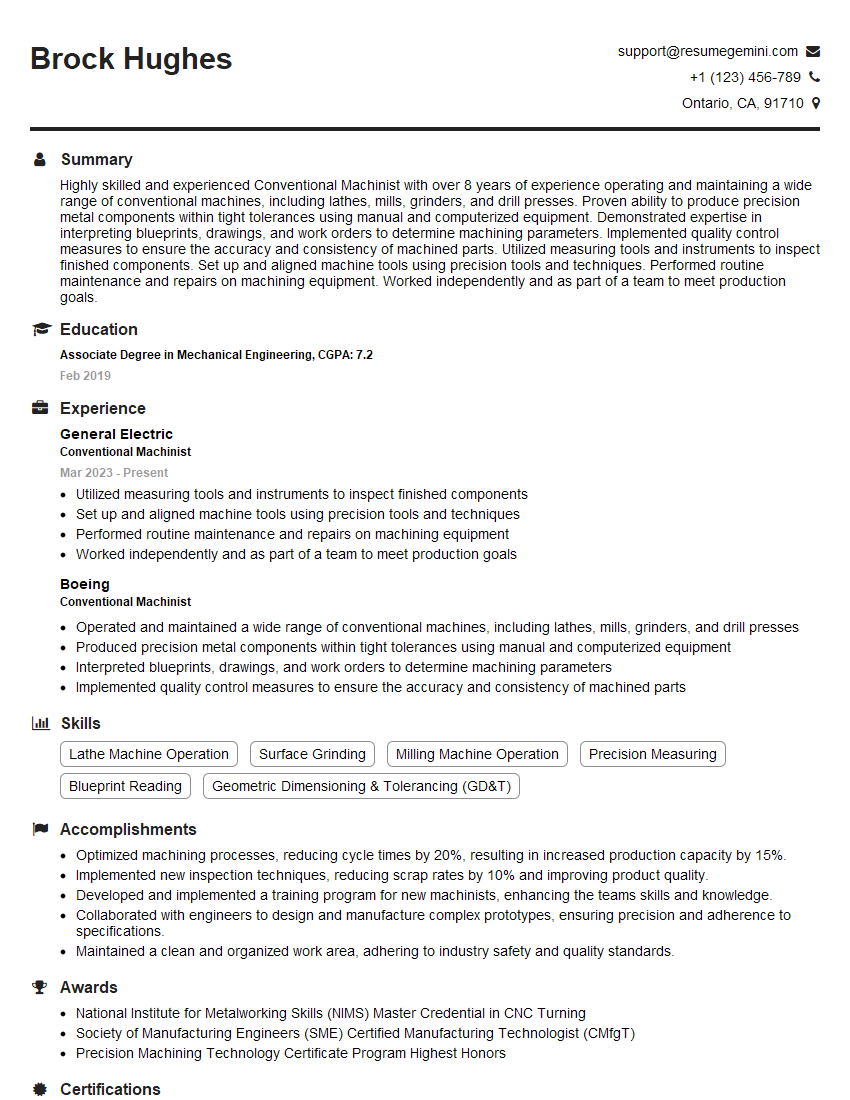

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conventional Machinist

1. What are the different types of conventional machining processes?

There are various types of conventional machining processes, including:

- Turning

- Milling

- Drilling

- Boring

- Shaping

- Planing

- Slotting

- Broaching

2. What are the key considerations when selecting cutting tools for conventional machining?

Factors to consider when selecting cutting tools for conventional machining:

- Material of the workpiece

- Type of machining operation

- Desired surface finish

- Tool geometry and cutting parameters

- Machine tool capabilities

Tool types:

- Single-point cutting tools (e.g., lathe tools)

- Multi-point cutting tools (e.g., milling cutters)

- Abrasive tools (e.g., grinding wheels)

3. How do you ensure the accuracy and precision of machined parts?

To ensure accuracy and precision, follow these steps:

- Use high-quality cutting tools and equipment

- Set up the machine tool properly

- Use accurate measuring instruments

- Follow established machining procedures

- Inspect parts regularly during and after machining

4. What are the common problems encountered in conventional machining and how do you troubleshoot them?

Common problems and troubleshooting tips:

- Chattering: Adjust cutting parameters or use a different tool geometry

- Tool breakage: Use the correct tool material, geometry, and cutting parameters

- Poor surface finish: Use a sharper tool or adjust cutting parameters

- Dimensional errors: Check machine setup, measuring instruments, and cutting tool accuracy

- Tool wear: Use appropriate tool materials and cutting parameters, or sharpen the tool

5. What are the safety precautions that must be followed when operating conventional machining equipment?

Ensure safety by adhering to these precautions:

- Wear appropriate safety gear

- Keep work area clean and organized

- Be aware of moving machine parts

- Use proper lifting techniques

- Follow established safety protocols

6. What types of materials can be machined using conventional machining processes?

Conventional machining can process a wide range of materials, including:

- Metals (e.g., steel, aluminum, brass)

- Plastics

- Wood

- Composites

- Ceramics (limited applications)

7. Describe the process of setting up a conventional lathe for a turning operation.

Steps to set up a conventional lathe:

- Mount the workpiece on the chuck or faceplate

- Select and mount the appropriate cutting tool

- Set the spindle speed and feed rate

- Adjust the tool height and position

- Run a test cut to verify settings

8. How do you calculate cutting speeds and feed rates for different materials and machining operations?

Use these formulas to calculate cutting speeds and feed rates:

Cutting speed:

- Vc = πDN / 1000 (m/min)

- Vc: cutting speed (m/min)

- D: workpiece diameter (mm)

- N: spindle speed (rpm)

Feed rate:

- f = N * z * s (mm/min)

- f: feed rate (mm/min)

- N: spindle speed (rpm)

- z: number of teeth or flutes

- s: feed per tooth or flute (mm/tooth)

Consider material properties, tool geometry, and surface finish requirements when selecting parameters.

9. What is the difference between absolute and incremental programming in CNC machining?

In CNC machining, programming can be either absolute or incremental:

Absolute programming:

- Coordinates are defined from a fixed reference point

- Each movement is specified as an absolute position

- Suitable for simple operations and when the starting point is known

Incremental programming:

- Coordinates are defined relative to the current position

- Each movement is specified as a change from the previous position

- Useful for complex operations and repetitive movements

10. Describe the role of coolant in conventional machining and its types.

Coolant plays a crucial role in conventional machining:

Functions of coolant:

- Lubricates and cools the cutting tool and workpiece

- Removes chips and debris from the cutting zone

- Extends tool life and improves surface finish

Types of coolant:

- Water-soluble: Most common, easy to use and dispose of

- Oil-based: Provides better lubrication, but can be more difficult to handle

- Synthetic: Combines properties of water-soluble and oil-based coolants

- Cryogenic: Uses liquid nitrogen or carbon dioxide for extreme cooling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conventional Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conventional Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conventional Machinists are responsible for operating, setting up, and maintaining a variety of machinery to produce precision parts and components. They work with various materials, including metals, plastics, and composites, and use a range of tools and techniques to create complex shapes and surfaces.

1. Machine Operation

Machining is the primary responsibility of a Conventional Machinist. They use a variety of machines to perform tasks such as cutting, drilling, grinding, and milling to create parts.

- Operate a variety of machine tools, including lathes, mills, drills, and grinders

- Interpret blueprints and technical drawings to determine machining specifications

- Set up and operate machines according to specified tolerances

- Monitor machines during operation to ensure precision and efficiency

2. Machine Maintenance

Conventional Machinists are also responsible for maintaining and repairing the machinery they use.

- Perform routine maintenance tasks, such as lubrication, cleaning, and calibration

- Troubleshoot and diagnose machine malfunctions

- Repair or replace damaged components

3. Quality Control

Conventional Machinists are responsible for ensuring the quality of the parts they produce.

- Inspect finished parts to ensure they meet specifications

- Make adjustments to machines or processes to improve quality

- Document and track quality control data

4. Safety

Conventional Machinists must follow safety protocols to ensure their own safety and the safety of others around them.

- Follow all safety regulations and procedures

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs

- Maintain a clean and organized work area

- Be aware of potential hazards and take steps to avoid them

Interview Tips

Preparing for an interview for a Conventional Machinist position can help you increase your chances of success. Here are some tips and tricks to help you ace your interview:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job posting carefully

- Talk to people in your network who work for the company

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in Conventional Machinist interviews. By preparing your answers to these questions ahead of time, you can increase your confidence and make a better impression on the interviewer.

- Tell me about your experience as a Conventional Machinist.

- What are your strengths and weaknesses as a Conventional Machinist?

- Why are you interested in this position?

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know what skills and experience you have that make you a good fit for the position. Be prepared to talk about your:

- Machine operation skills

- Machine maintenance skills

- Quality control skills

- Safety knowledge

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about their work. Show the interviewer that you’re passionate about machining and that you’re excited about the opportunity to work for the company.

- Smile and make eye contact with the interviewer

- Speak clearly and confidently

- Be positive and upbeat

Next Step:

Now that you’re armed with the knowledge of Conventional Machinist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Conventional Machinist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini