Are you gearing up for a career in Converter Skimmer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Converter Skimmer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

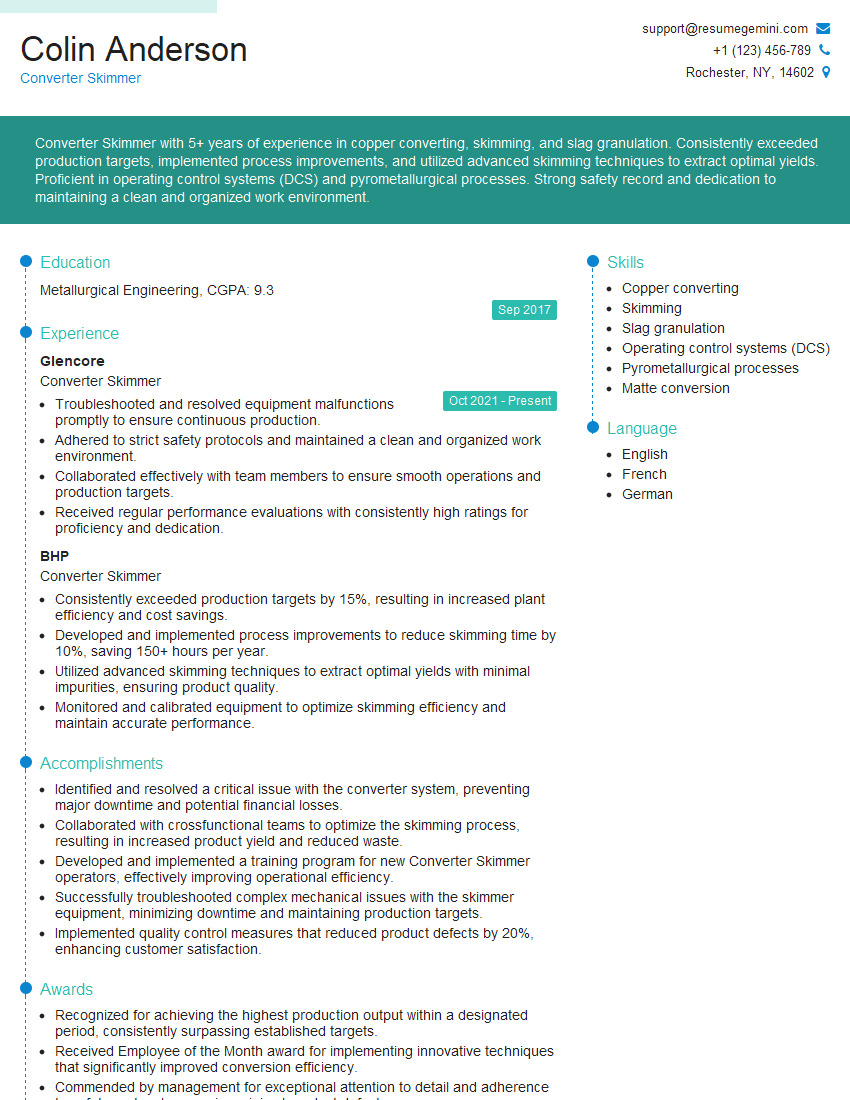

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Converter Skimmer

1. What are the key principles and processes involved in the design and operation of a converter skimmer?

The design and operation of a converter skimmer involve several key principles and processes. These include:

- Feed preparation: The raw ore is crushed and ground into a fine powder, which is then mixed with water to form a slurry.

- Froth flotation: The slurry is agitated to create a froth, which contains the valuable minerals. The froth is then skimmed off the top of the slurry.

- Concentration: The froth is thickened and concentrated to increase the grade of the mineral concentrate.

- Dewatering: The concentrate is dewatered to remove excess water and produce a dry product.

2. Describe the role of a converter skimmer in the copper production process.

Copper recovery

- Converter skimmers are used to recover copper from converter slag. Converter slag is a byproduct of the copper smelting process, and it contains significant amounts of copper that would otherwise be lost.

- The converter skimmer floats the copper-bearing slag particles to the surface of the slag bath, where they are skimmed off and collected.

Environmental protection

- Converter skimmers also play an important role in environmental protection. By recovering copper from converter slag, they reduce the amount of copper that is released into the environment.

- Copper is a toxic metal, and its release into the environment can have harmful effects on human health and the ecosystem.

3. How is the efficiency of a converter skimmer measured?

The efficiency of a converter skimmer is measured by its recovery rate. The recovery rate is the percentage of copper that is recovered from the converter slag. A high recovery rate indicates that the skimmer is efficiently recovering the copper from the slag.

4. What are the factors that affect the efficiency of a converter skimmer?

- Slag composition: The composition of the converter slag can affect the efficiency of the skimmer. Slags that are high in copper content will produce higher recovery rates than slags that are low in copper content.

- Slag temperature: The temperature of the converter slag can also affect the efficiency of the skimmer. Higher temperatures can reduce the viscosity of the slag, which makes it easier for the skimmer to float the copper-bearing particles to the surface.

- Skimmer design: The design of the skimmer can also affect its efficiency. Skimmers with larger surface areas will have higher recovery rates than skimmers with smaller surface areas.

5. What are the different types of converter skimmers?

- Mechanical skimmers: Mechanical skimmers use mechanical means to remove the copper-bearing slag from the surface of the slag bath. These skimmers typically consist of a rotating drum or wheel that is partially submerged in the slag bath.

- Air skimmers: Air skimmers use air to remove the copper-bearing slag from the surface of the slag bath. These skimmers typically consist of a series of air jets that are directed at the surface of the slag bath.

6. What are the advantages and disadvantages of mechanical skimmers?

Advantages

- High recovery rates

- Low maintenance costs

- Simple to operate

Disadvantages

- Can be damaged by slag build-up

- Can be difficult to operate in high-temperature environments

7. What are the advantages and disadvantages of air skimmers?

Advantages

- High recovery rates

- Can be operated in high-temperature environments

- Easy to maintain

Disadvantages

- Higher maintenance costs than mechanical skimmers

- Can be more difficult to operate

8. What are the safety considerations when operating a converter skimmer?

- Converter skimmers can operate at high temperatures, so it is important to wear appropriate protective clothing and equipment.

- Converter skimmers can also produce hazardous fumes, so it is important to ensure that the area is well-ventilated.

- Converter skimmers can be noisy, so it is important to wear hearing protection.

9. What are the maintenance requirements for a converter skimmer?

- Converter skimmers require regular maintenance to ensure that they are operating efficiently and safely.

- Maintenance tasks typically include cleaning the skimmer, inspecting the mechanical components, and replacing worn parts.

- The frequency of maintenance will vary depending on the type of skimmer and the operating conditions.

10. What are the future trends in converter skimmer technology?

- Converter skimmer technology is constantly evolving to improve efficiency and reduce costs.

- Some of the latest trends in converter skimmer technology include the use of new materials, the development of more efficient designs, and the integration of automation.

- These trends are expected to continue in the future, as the demand for copper continues to grow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Converter Skimmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Converter Skimmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Converter Skimmers are responsible for operating and maintaining equipment that converts molten steel into a solid state. They must have a strong understanding of the steelmaking process and the equipment used in the conversion process.

1. Operate Converter Skimmer Equipment

Converter Skimmers operate a variety of equipment, including:

- Top-blown oxygen converter (TBOF)

- Bottom-blown oxygen converter (BOF)

- Electric arc furnace (EAF)

- Ladle furnace (LF)

2. Monitor and Control Steelmaking Process

Converter Skimmers monitor and control the steelmaking process to ensure that the steel meets the desired specifications. They must be able to identify and correct any problems that may arise during the process.

- Monitor the temperature of the steel

- Control the flow of oxygen and other gases into the converter

- Sample and analyze the steel to ensure that it meets the desired specifications

3. Maintain Equipment

Converter Skimmers are responsible for maintaining the equipment that they use. They must be able to identify and repair any problems that may arise with the equipment.

- Inspect the equipment for any damage or wear

- Lubricate and adjust the equipment as needed

- Replace any worn or damaged parts

4. Work Safely

Converter Skimmers must work safely in a potentially hazardous environment. They must be aware of the hazards associated with the steelmaking process and take steps to protect themselves and others from injury.

- Wear appropriate safety gear, including hard hats, safety glasses, and gloves

- Follow all safety procedures

- Report any unsafe conditions to their supervisor

Interview Tips

In order to ace the interview, candidates should:

1. Research the company and the position

Candidates should take the time to research the company they are applying to and the specific position they are interested in. This will help them understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice answering common interview questions

Candidates should practice answering common interview questions so that they can feel confident and prepared during the interview. There are many resources available online and in libraries that can help candidates prepare for common interview questions.

- What are your strengths and weaknesses?

- Why are you interested in this position?

- What are your career goals?

3. Dress professionally

Candidates should dress professionally for the interview. This means wearing a suit or dress pants and a button-down shirt. They should also make sure their shoes are clean and their hair is neat.

4. Arrive on time

Candidates should arrive on time for the interview. This shows that they are respectful of the interviewer’s time and that they are serious about the position.

5. Be yourself

Candidates should be themselves during the interview. This means being honest and authentic. Interviewers can tell when someone is being fake, so it is important to be genuine.

- Be honest about your experience and qualifications

- Be authentic and let your personality shine through

- Be confident and believe in yourself

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Converter Skimmer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Converter Skimmer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.