Are you gearing up for a career in Converting Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Converting Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

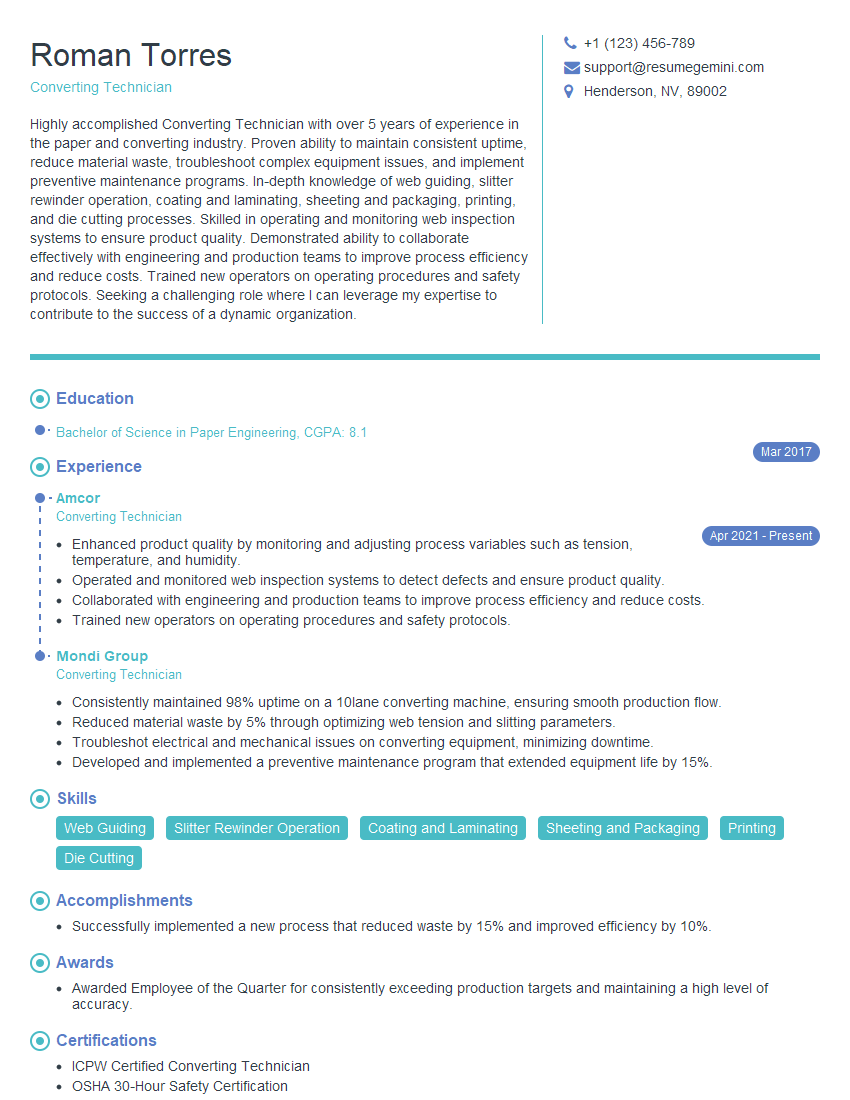

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Converting Technician

1. Explain the process of converting a 2D drawing into a 3D model.

The process of converting a 2D drawing into a 3D model involves several steps:

- Extrusion: Extruding the 2D drawing to create a 3D shape.

- Revolve: Revolving the 2D drawing around an axis to create a 3D object.

- Boolean operations: Using Boolean operations (union, intersection, subtraction) to combine multiple 2D drawings into a single 3D model.

- Surface modeling: Creating 3D surfaces by manipulating points, curves, and surfaces.

- Solid modeling: Creating 3D solids by defining their boundaries and properties.

2. What are the different types of 3D printing technologies?

Fused Deposition Modeling (FDM)

- Uses a heated nozzle to deposit melted plastic filament, layer by layer.

- Pros: Low cost, easy to use, wide range of materials.

- Cons: Limited resolution, can produce rough surfaces.

Stereolithography (SLA)

- Uses a laser to cure liquid resin, layer by layer.

- Pros: High resolution, smooth surfaces, accurate.

- Cons: More expensive, requires post-processing.

Selective Laser Sintering (SLS)

- Uses a laser to sinter powdered material, layer by layer.

- Pros: Produces strong, durable parts with complex geometries.

- Cons: More expensive, requires post-processing.

3. What are the factors to consider when choosing a 3D printing material?

Factors to consider when choosing a 3D printing material include:

- Strength: The material’s ability to withstand stress and deformation.

- Flexibility: The material’s ability to bend without breaking.

- Durability: The material’s resistance to wear and tear.

- Temperature resistance: The material’s ability to withstand high or low temperatures.

- Biocompatibility: The material’s compatibility with living tissue.

- Cost: The material’s cost per unit volume.

4. What is the difference between additive and subtractive manufacturing?

Additive manufacturing (3D printing): Builds up a 3D object by adding material layer by layer.

Subtractive manufacturing (CNC machining): Removes material from a solid block to create a 3D object.

Advantages of additive manufacturing:

- Produces complex geometries.

- Reduces waste.

- Can use a wide range of materials.

Advantages of subtractive manufacturing:

- Produces high-precision parts.

- Suitable for mass production.

- Can process a wide range of materials.

5. What are the different types of CNC machines and their applications?

Types of CNC Machines:

- Milling machines: Used for cutting and shaping metals and plastics.

- Lathes: Used for turning and cutting cylindrical parts.

- 3D printers: Used for creating 3D objects from a variety of materials.

- Waterjet cutters: Used for cutting through a variety of materials, including metals, plastics, and composites.

- Plasma cutters: Used for cutting through metal using a plasma arc.

Applications:

- Manufacturing

- Prototyping

- Art and design

- Medical devices

- Aerospace

6. What is G-code and how is it used in CNC machining?

G-code is a programming language used to control CNC machines. It consists of a series of commands that define the machine’s movements, toolpath, and other parameters.

Types of G-code commands:

- Motion commands: Control the machine’s movements, such as G0 (rapid movement) and G1 (linear movement).

- Tooling commands: Control the tool’s selection, speed, and feed rate.

- Coordinate system commands: Define the machine’s coordinate system and tool offsets.

- Miscellaneous commands: Control the machine’s coolant, spindle, and other auxiliary functions.

7. What is CAM software and how is it used in CNC machining?

CAM (Computer-aided manufacturing) software is used to generate G-code for CNC machines. It allows the user to create 3D models of the part to be machined, define the toolpath, and simulate the machining process.

Benefits of using CAM software:

- Reduces programming time.

- Improves the accuracy and efficiency of CNC machining.

- Allows for simulation and optimization of the machining process.

8. What are the different factors that affect the quality of a CNC machined part?

Factors affecting the quality of a CNC machined part include:

- Machine accuracy: The precision of the CNC machine.

- Tool selection: The type and condition of the cutting tool.

- Material properties: The hardness, strength, and other characteristics of the material being machined.

- Machining parameters: The speed, feed rate, and depth of cut.

- CAM software: The quality of the G-code generated by the CAM software.

9. What are the safety precautions to be taken when operating a CNC machine?

Safety precautions to be taken when operating a CNC machine include:

- Wear appropriate safety gear, including safety glasses, gloves, and ear protection.

- Keep the work area clean and free of debris.

- Secure the workpiece properly before starting the machine.

- Never enter the machine’s operating zone while it is running.

- Be aware of the machine’s potential hazards, such as moving parts, sharp edges, and electrical hazards.

10. How do you troubleshoot common problems that occur during CNC machining?

Common problems that occur during CNC machining and their troubleshooting steps include:

- Tool breakage: Check the tool for wear, damage, or improper selection.

- Surface finish issues: Adjust the machining parameters, such as speed, feed rate, or depth of cut.

- Dimensional errors: Check the machine accuracy, tool offsets, and CAM software settings.

- Coolant problems: Check the coolant level, flow rate, and filter.

- Electrical faults: Check the electrical connections, wiring, and circuit breakers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Converting Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Converting Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Converting Technician plays a crucial role in the production process, ensuring the smooth conversion of raw materials into high-quality finished products.

1. Operating Converting Machinery

The primary duty is to operate and maintain converting machinery, including slitter/rewinders, laminators, sheeting lines, and extruders.

- Set up and adjust machines to meet production specifications.

- Monitor machine performance and troubleshoot any issues.

- Ensure optimal production efficiency and minimize downtime.

2. Material Handling and Inspection

Handle and inspect raw materials and finished products to ensure quality and compliance.

- Inspect materials for defects and damage.

- Maintain inventory and ensure proper storage of materials.

- Follow established quality control procedures.

3. Production Planning and Monitoring

Collaborate with production teams to plan and monitor production schedules.

- Estimate production timelines and identify potential bottlenecks.

- Track production progress and adjust operations as needed.

- Analyze production data to identify areas for improvement.

4. Safety and Compliance

Maintain a safe work environment and comply with all relevant safety regulations.

- Wear appropriate safety gear and follow safety protocols.

- Identify and mitigate potential hazards.

- Stay up-to-date on industry safety practices.

Interview Tips

Preparing for a Converting Technician interview is crucial to showcase your skills and secure the position. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company and the specific role to gain a clear understanding of their business, culture, and expectations.

- Visit the company website to learn about their products, services, and mission.

- Read industry publications and articles to stay abreast of the latest trends.

- Connect with current or former employees on LinkedIn to gain insights.

2. Highlight Your Technical Skills

Emphasize your technical expertise in operating converting machinery and your knowledge of production processes.

- Provide specific examples of your experience in setting up and troubleshooting machines.

- Quantify your accomplishments, such as reducing downtime or improving production efficiency.

- Discuss your understanding of quality control procedures and safety regulations.

3. Demonstrate Problem-Solving Abilities

Interviewers seek candidates with strong problem-solving skills. Be prepared to share examples of how you have identified and resolved issues in a production setting.

- Describe a situation where you encountered a technical problem and explain the steps you took to resolve it.

- Emphasize your ability to think critically and find innovative solutions.

- Discuss your willingness to learn and seek guidance when necessary.

4. Show Your Passion for the Industry

Convey your enthusiasm for the converting industry and explain why you are eager to contribute your skills.

- Share your knowledge of industry trends and how they may impact the company’s operations.

- Express your interest in learning and growing within the field.

Next Step:

Now that you’re armed with the knowledge of Converting Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Converting Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini