Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Convex Grinder Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Convex Grinder Operator so you can tailor your answers to impress potential employers.

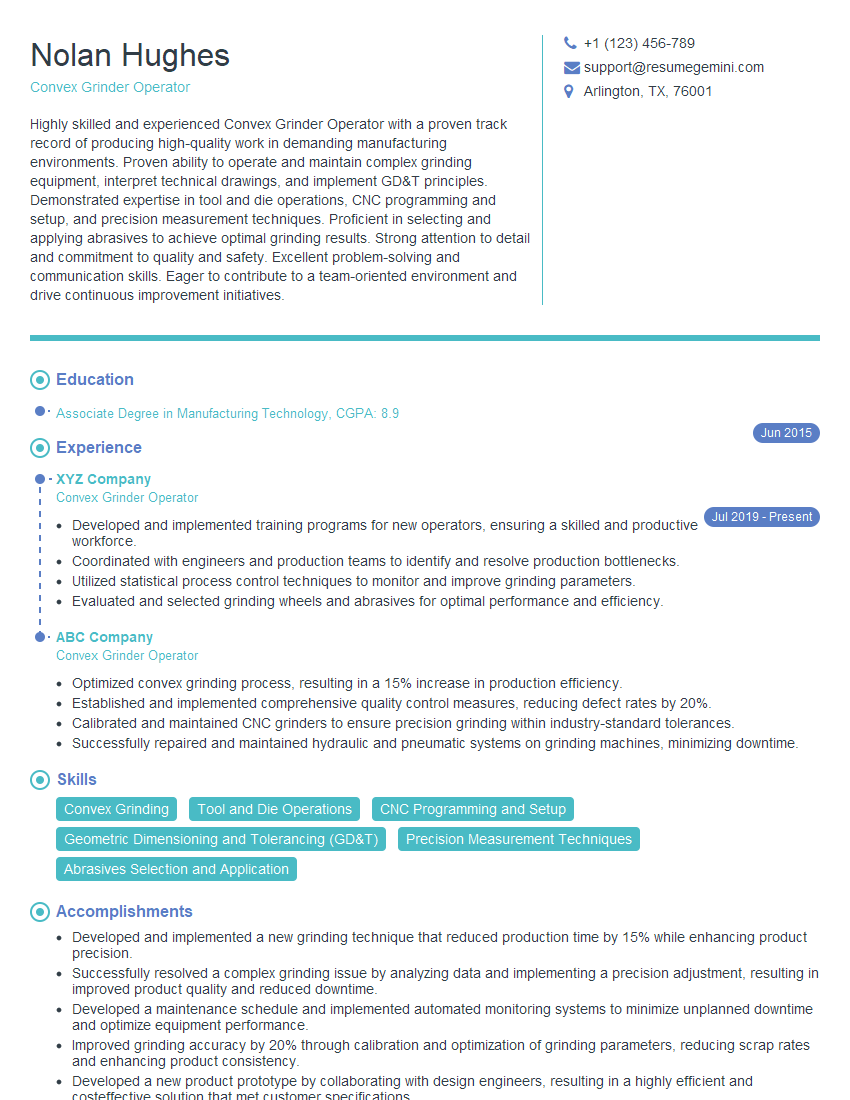

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Convex Grinder Operator

1. Describe the key responsibilities of a Convex Grinder Operator.

The primary responsibilities typically include:

- Operating and monitoring convex grinding machines to produce precision components.

- Setting up, adjusting, and calibrating machines according to specifications.

- Inspecting and measuring parts to ensure they meet tolerances and quality standards.

- Maintaining and troubleshooting machines to ensure optimal performance.

- Following safety procedures and adhering to established guidelines.

2. What are the essential safety precautions one should observe while operating a convex grinding machines?

General Safety Measures

- Wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and earplugs.

- Keep the work area clean and organized to prevent tripping hazards.

- Ensure proper ventilation to avoid exposure to harmful dust and fumes.

- Inspect the machine and tooling regularly for any signs of damage or wear.

Machine-Specific Precautions

- Make sure the machine is properly grounded to prevent electrical shocks.

- Securely mount the workpiece to prevent it from flying out during operation.

- Never reach into the grinding area while the machine is running.

- Use the proper grinding wheels and speeds for the material being ground.

3. How do you determine the correct grinding wheel for a specific application?

The selection of the appropriate grinding wheel depends on several factors:

- Material of the workpiece: Different materials require different abrasive types and bond strengths.

- Size and shape of the workpiece: The size and shape of the wheel must be compatible with the workpiece.

- Required surface finish: Different wheel grits and grades produce different surface finishes.

- Machine capabilities: The grinding machine’s speed and power must be matched to the wheel’s specifications.

- Cost and availability: Consider the cost and availability of different wheel options.

4. Describe the process of setting up and calibrating a convex grinding machine.

Setting up and calibrating a convex grinding machine typically involves the following steps:

- Mounting the grinding wheel: Ensure the wheel is properly mounted and balanced.

- Adjusting the wheel speed and feed rate: Set the speed and feed rate according to the manufacturer’s recommendations.

- Dressing the grinding wheel: Dress the wheel to achieve the desired shape and surface finish.

- Mounting the workpiece: Securely mount the workpiece to the machine’s table.

- Calibrating the machine: Use precision measuring instruments to calibrate the machine’s axes and ensure accuracy.

5. How do you inspect and measure parts to ensure they meet tolerances and quality standards?

Inspection and measurement are crucial to ensure parts meet specifications:

- Visual inspection: Examine the parts for any visible defects or imperfections.

- Dimensional measurement: Use precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs) to measure critical dimensions.

- Surface finish measurement: Use surface roughness testers to measure the surface finish and ensure it meets the required specifications.

- Hardness testing: Perform hardness tests to verify that the parts meet the specified hardness requirements.

- Functional testing: Conduct functional tests to assess the performance of the parts in actual operating conditions.

6. What are some common troubleshooting techniques for convex grinding machines?

Troubleshooting techniques include:

- Vibration or noise: Check for loose components, unbalanced wheels, or worn bearings.

- Poor surface finish: Inspect the grinding wheel for wear or damage, adjust the feed rate or wheel speed.

- Inaccurate dimensions: Calibrate the machine, check for worn tooling, or adjust the machine settings.

- Overheating: Check for clogged coolant lines, inspect the workpiece for excessive material buildup, or adjust the grinding parameters.

- Electrical faults: Inspect electrical connections, check for loose wires, or contact a qualified electrician.

7. How do you maintain a convex grinding machine to ensure optimal performance and longevity?

Regular maintenance is essential for optimal performance and longevity:

- Cleaning: Regularly clean the machine to remove dust, debris, and coolant buildup.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Inspection: Inspect the machine regularly for signs of wear or damage.

- Preventive maintenance: Perform scheduled maintenance tasks to replace worn components and prevent major breakdowns.

- Training: Ensure operators are properly trained to operate and maintain the machine effectively.

8. What are the potential hazards associated with convex grinding operations, and how can they be mitigated?

Potential hazards include:

- Dust and fumes: Use proper ventilation and respiratory protection.

- Eye injuries: Wear safety glasses or goggles.

- Cuts and abrasions: Wear gloves and avoid reaching into the grinding area.

- Electrical hazards: Ensure proper grounding and inspect electrical connections regularly.

- Noise: Use hearing protection.

9. How do you stay updated on the latest advancements in convex grinding technology and best practices?

To stay updated:

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Consult with manufacturers and equipment suppliers.

- Seek opportunities for professional development and training.

10. How do you handle situations where you encounter problems or challenges that require creative solutions?

When faced with challenges, I typically:

- Analyze the problem: Gather information, identify root causes, and consider different perspectives.

- Brainstorm solutions: Explore various options, both conventional and unconventional.

- Evaluate solutions: Assess the feasibility, potential risks, and benefits of each solution.

- Implement and monitor: Put the chosen solution into action and track its effectiveness.

- Seek support: Consult with colleagues, supervisors, or experts if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Convex Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Convex Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Convex Grinder Operator is responsible for operating and maintaining convex grinding machines used in the production of various tools and components. Their key responsibilities include:

1. Operating Convex Grinding Machines

Convex Grinder Operators are skilled in setting up, operating, and monitoring convex grinding machines to produce precise and accurate parts. They ensure that the machine is properly calibrated and adjusted to meet the required specifications.

- Loading and unloading workpieces into the machine

- Selecting and installing appropriate grinding wheels

- Adjusting machine settings such as speed, feed rate, and depth of cut

- Monitoring the grinding process to ensure quality and accuracy

2. Maintaining Grinding Machines

To ensure optimal performance and prevent breakdowns, Convex Grinder Operators are responsible for maintaining their machines regularly. This includes:

- Cleaning and lubricating machine components

- Inspecting and replacing worn or damaged parts

- Performing minor repairs and adjustments

- Following established maintenance schedules

3. Quality Control

Convex Grinder Operators are responsible for ensuring the quality of the parts produced by the grinding machines. They:

- Inspect finished parts to verify dimensions, tolerances, and surface finish

- Make adjustments to machine settings or workholding fixtures as needed

- Record and maintain quality control data

4. Safety and Compliance

Convex Grinder Operators are committed to maintaining a safe and compliant work environment. They:

- Follow established safety protocols and wear appropriate personal protective equipment

- Ensure that the grinding machine is properly guarded and meets safety standards

- Comply with all relevant environmental regulations

Interview Tips

To prepare for an interview as a Convex Grinder Operator, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific role and its responsibilities to demonstrate your interest and understanding.

- Visit the company’s website and social media pages

- Read industry publications and articles

- Network with people in the field

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in operating and maintaining convex grinding machines. Quantify your accomplishments and provide specific examples of your contributions.

- Mention your experience with different types of grinding machines

- Showcase your knowledge of quality control procedures

- Highlight your ability to work independently and as part of a team

3. Prepare for Technical Questions

Be prepared to answer technical questions about convex grinding processes, machine operation, and maintenance procedures. Review common industry terminology and concepts.

- Explain the principles of convex grinding

- Describe different types of grinding wheels and their applications

- Discuss common troubleshooting techniques

4. Practice Your Answers

Practice answering common interview questions aloud or with a friend. This will help you articulate your thoughts clearly and confidently.

- Prepare answers to questions about your experience, skills, and motivations

- Consider potential behavioral questions and prepare examples

- Time yourself to ensure you can deliver concise and thoughtful answers

5. Dress Professionally and Arrive Prepared

Make a good first impression by dressing professionally and arriving on time for your interview. Bring a copy of your resume and any relevant certifications or documents.

- Choose attire that is clean, pressed, and appropriate for an industrial setting

- Arrive early to allow time for check-in and to compose yourself

- Bring a portfolio or examples of your work if relevant

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Convex Grinder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Convex Grinder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.