Feeling lost in a sea of interview questions? Landed that dream interview for Conveyor Belt Installer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Conveyor Belt Installer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

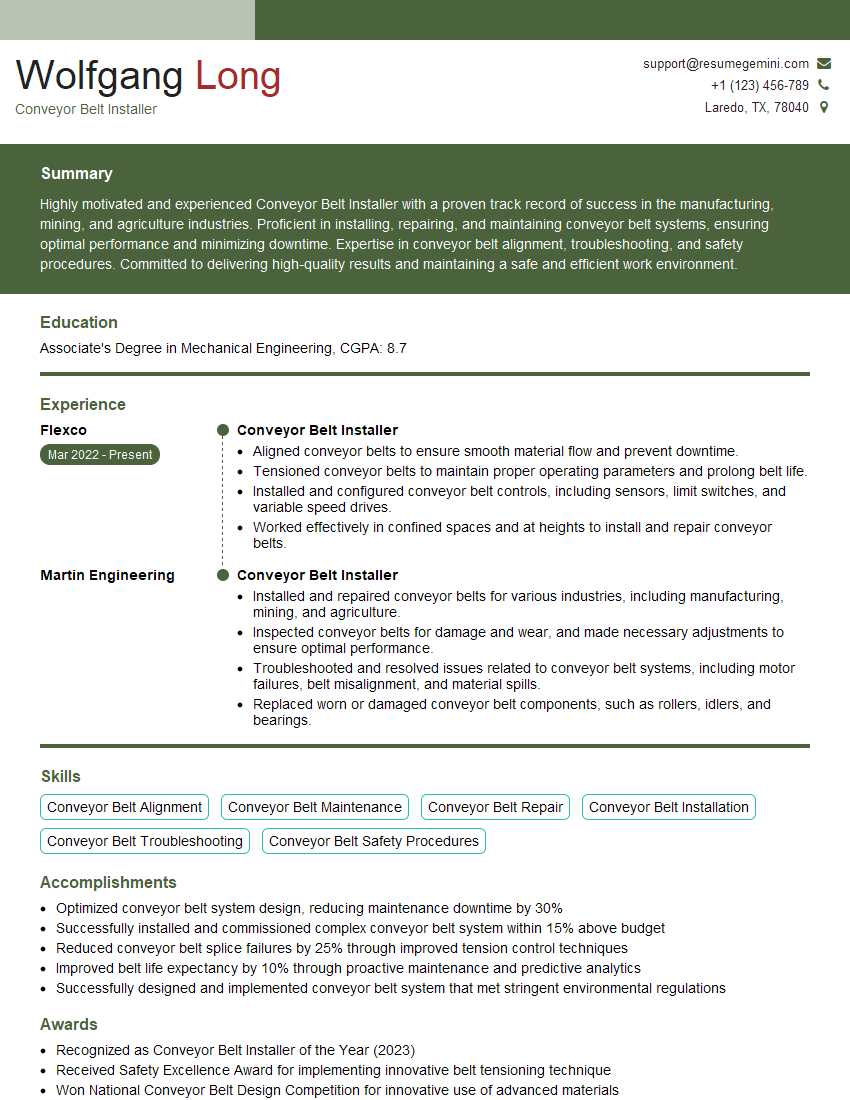

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conveyor Belt Installer

1. Explain the key factors to consider when selecting a conveyor belt?

The key factors to consider when selecting a conveyor belt include:

- Material to be conveyed: The type of material being transported will determine the belt’s strength, thickness, and coating requirements.

- Belt width and length: The width and length of the belt must be sufficient to handle the volume and weight of the material being conveyed.

- Speed and capacity: The belt’s speed and capacity must meet the production requirements.

- Operating environment: The belt must be suitable for the operating environment, including temperature, humidity, and chemical exposure.

- Maintenance and repair requirements: The belt should be easy to maintain and repair to minimize downtime.

2. Describe the steps involved in installing a conveyor belt.

Pre-installation:

- Inspect the equipment and ensure it meets specifications.

- Clean and prepare the area where the conveyor will be installed.

- Assemble the conveyor frame and supports.

Belt installation:

- Unroll the belt onto the conveyor frame.

- Tension the belt using the recommended tensioning method.

- Align the belt with the pulleys and idlers.

Post-installation:

- Test run the conveyor to ensure proper operation.

- Lubricate the conveyor components as required.

- Provide training on the operation and maintenance of the conveyor.

3. How do you determine the tension of a conveyor belt?

The tension of a conveyor belt can be determined using a variety of methods, including:

- Tension meter: This device measures the tension directly on the belt.

- Belt deflection: The deflection of the belt between two pulleys can be used to calculate the tension.

- Sound frequency: The frequency of sound produced by the belt when it is struck can be used to estimate the tension.

4. What are the common causes of conveyor belt failure?

Common causes of conveyor belt failure include:

- Mechanical damage: This can be caused by impact, abrasion, or cutting.

- Chemical damage: This can be caused by exposure to chemicals or solvents.

- Heat damage: This can be caused by exposure to high temperatures.

- Electrical damage: This can be caused by electrical faults or lightning strikes.

- Wear and tear: This is a natural process that occurs over time.

5. How do you prevent conveyor belt damage?

Preventing conveyor belt damage involves:

- Regular inspection and maintenance: This includes checking for any signs of damage, wear and tear, or misalignment.

- Proper operation: Following the manufacturer’s instructions for operation, including proper loading and unloading procedures.

- Protecting the belt from damage: Installing guards or covers to protect the belt from impact, abrasion, or chemical exposure.

- Using high-quality belts: Using belts that are specifically designed for the application and environment.

- Training operators: Providing training to operators on how to properly operate and maintain the conveyor.

6. What are the different types of conveyor belt splices?

There are several types of conveyor belt splices, including:

- Mechanical splice: This type of splice uses metal fasteners to connect the belt ends.

- Vulcanized splice: This type of splice uses heat and pressure to fuse the belt ends together.

- Finger splice: This type of splice uses interlocking fingers to connect the belt ends.

- Sewn splice: This type of splice uses heavy-duty thread to stitch the belt ends together.

7. How do you maintain a conveyor belt system?

Maintaining a conveyor belt system involves:

- Regular inspection: Checking for any signs of damage, wear and tear, or misalignment.

- Cleaning: Removing any debris or buildup from the belt and equipment.

- Lubrication: Lubricating the bearings, pulleys, and other moving parts.

- Tensioning: Adjusting the belt tension to ensure proper operation.

- Repairs: Replacing any damaged or worn components.

8. What safety precautions should be taken when working with conveyor belts?

When working with conveyor belts, safety precautions include:

- Lockout/tagout: Ensuring that the conveyor is properly locked out and tagged out before performing any maintenance or repairs.

- Wear appropriate PPE: Wearing appropriate personal protective equipment, including safety glasses, gloves, and sturdy footwear.

- Stay clear of moving belts: Keeping a safe distance from moving belts and avoiding any contact with them.

- Be aware of pinch points: Identifying and avoiding any potential pinch points where the belt could crush or entrap a person.

- Follow safety procedures: Following all established safety procedures and guidelines.

9. How do you troubleshoot common conveyor belt problems?

Common conveyor belt problems and their troubleshooting steps include:

- Belt tracking issues: Adjusting the belt tension, aligning the pulleys and idlers, or replacing worn or damaged components.

- Material carryback: Installing skirting or scrapers to prevent material from falling off the belt.

- Belt slippage: Increasing the belt tension, replacing worn or damaged drive pulleys, or cleaning the belt surface.

- Excessive belt wear: Replacing worn or damaged belts, adjusting the belt tension, or improving the material handling process.

- Electrical problems: Troubleshooting electrical connections, replacing faulty motors or components, or contacting an electrician.

10. What is your experience with different types of conveyor systems?

In my previous role as a Conveyor Belt Installer, I have extensive experience with various conveyor systems, including:

- Belt conveyors: Installing and maintaining belt conveyors used for transporting bulk materials.

- Chain conveyors: Installing and maintaining chain conveyors used for transporting individual items or packages.

- Roller conveyors: Installing and maintaining roller conveyors used for moving products through a production or distribution facility.

- Screw conveyors: Installing and maintaining screw conveyors used for transporting materials in a continuous flow.

- Pneumatic conveyors: Installing and maintaining pneumatic conveyors used for transporting materials using air pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conveyor Belt Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conveyor Belt Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conveyor Belt Installers play a central role in the installation, maintenance, and repair of conveyor belt systems, which are crucial for the efficient movement of materials in various industries.

1. Installation

Collaborating with engineers and project managers, they determine the layout and specifications of the conveyor belt system based on the site requirements.

- Prepare the site by excavating, leveling, and constructing support structures.

- Assemble and install conveyor components, including idlers, rollers, pulleys, and drive systems.

- Splice and tension the conveyor belt, ensuring proper alignment and tracking.

2. Maintenance

Regularly inspect and maintain conveyor belt systems to prevent breakdowns and ensure optimal performance.

- Inspect belts for wear, damage, or misalignment.

- Lubricate and adjust components to minimize friction and extend the lifespan of the system.

- Monitor belt tension and make adjustments as needed.

3. Troubleshooting and Repair

Troubleshoot and resolve issues that arise with conveyor belt systems.

- Identify and diagnose faults through observation, testing, and analysis.

- Repair or replace damaged components, such as bearings, pulleys, or belts.

- Adjust settings and make modifications to improve system performance or efficiency.

4. Safety Compliance

Adhere to all safety regulations and protocols to ensure the well-being of workers and the overall safety of the work environment.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures when servicing or repairing equipment.

- Report any safety hazards or concerns promptly to supervisors.

Interview Preparation Tips

To ace your interview for a Conveyor Belt Installer position, consider the following tips and strategies:

1. Research the Company and Industry

Familiarize yourself with the company’s website, social media pages, and industry publications to gain insights into their operations, culture, and recent developments.

- Research the specific industry where the company operates to understand the market trends and technological advancements.

2. Highlight Relevant Experience and Skills

Carefully review the job description and identify the key skills and experience required. Emphasize your proficiency in installing, maintaining, and repairing conveyor belt systems.

- Quantify your accomplishments using specific metrics and examples to demonstrate your impact.

3. Prepare for Technical Questions

Gather information about common conveyor belt system designs, components, and troubleshooting techniques. Review industry standards and safety protocols.

- Practice answering questions about specific types of conveyors, such as belt conveyors, roller conveyors, or bucket elevators.

4. Understand Basic Mechanical Principles

Have a good understanding of basic mechanical principles, such as tension, friction, and pulleys. This knowledge will help you better comprehend conveyor belt system operations and troubleshooting.

- Consider reviewing textbooks or online resources to refresh your knowledge in these areas.

5. Be Prepared for Situational Questions

Anticipate questions that may require you to describe how you would handle specific situations or challenges on the job.

- Prepare examples from your past experiences where you demonstrated problem-solving skills, attention to detail, and teamwork.

6. Dress Professionally and Arrive on Time

Make a good impression by dressing appropriately and arriving for your interview on time. Demonstrate your professionalism and respect for the interviewer’s schedule.

- Choose business attire that is clean, pressed, and fits you well.

7. Ask Thoughtful Questions

At the end of the interview, ask questions that show your interest in the position and the company. This can help you gauge the company’s culture and growth opportunities.

- Prepare questions related to the company’s future projects, training opportunities, or their commitment to safety.

Next Step:

Now that you’re armed with the knowledge of Conveyor Belt Installer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Conveyor Belt Installer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini