Are you gearing up for an interview for a Conveyor Loader position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Conveyor Loader and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

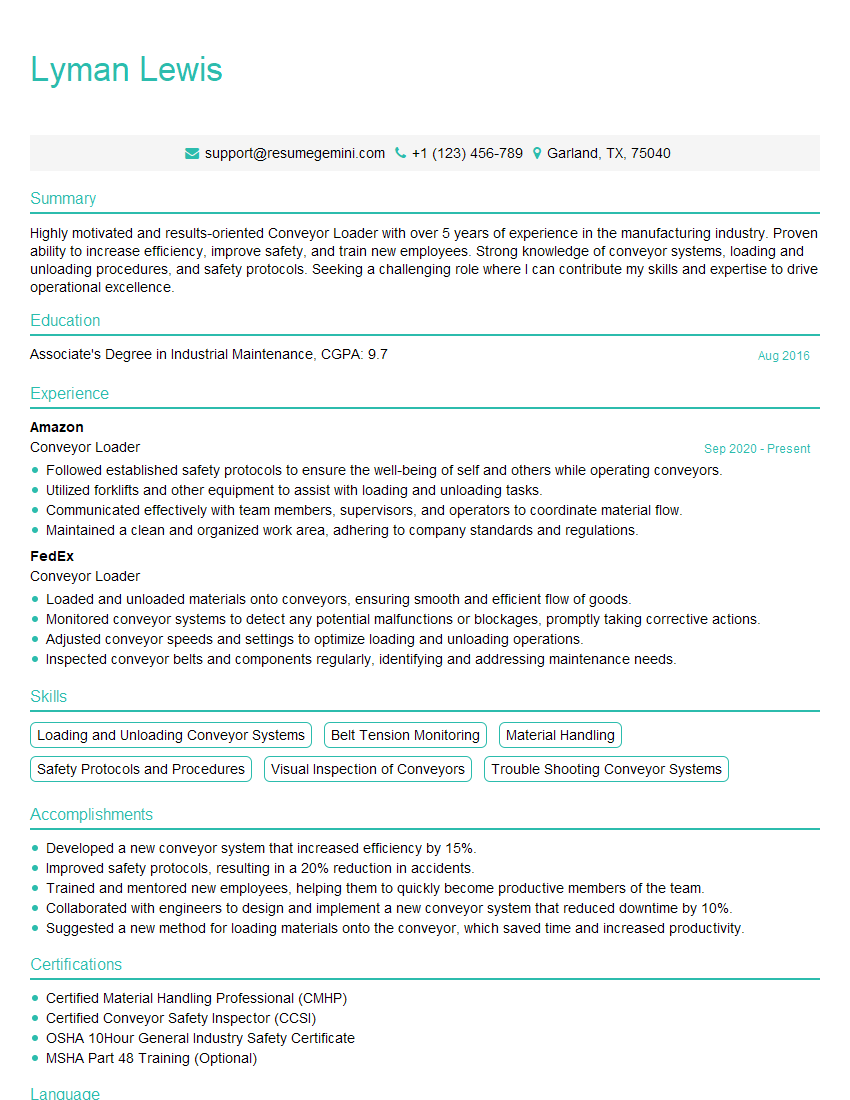

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conveyor Loader

1. How would you troubleshoot a conveyor belt that is not moving?

- Check if the power source is functioning correctly.

- Inspect the drive system, including the motor, gearbox, and belts, for any damage or misalignment.

- Verify that the tension on the conveyor belt is adequate.

- Examine the conveyor rollers and idlers for any obstructions or misalignment.

2. Describe the steps involved in replacing a worn-out conveyor belt.

Safety Considerations:

- Ensure that the conveyor is de-energized and locked out before starting work.

- Install barricades or warning signs to prevent access to the work area.

Belt Removal:

- Cut the old belt at a marked or convenient point.

- Use a belt removal tool to separate the belt from the rollers.

- Remove the belt from the conveyor frame.

Belt Installation:

- Clean the conveyor frame and rollers.

- Align the new belt on the conveyor frame.

- Lace or vulcanize the belt ends together.

- Adjust the tension on the belt.

3. How do you maintain the cleanliness and lubrication of a conveyor system?

- Regularly sweep or vacuum the conveyor frame and components to remove debris.

- Use compressed air to clean accumulated dust and dirt.

- Lubricate all moving parts, such as bearings, rollers, and chains, according to the manufacturer’s specifications.

- Inspect and replace lubrication fittings as needed.

4. Discuss the potential hazards associated with working on conveyor systems.

- Caught-in hazards: Entanglement in moving belts, rollers, or machinery.

- Struck-by hazards: Contact with falling or moving objects.

- Electrical hazards: Exposure to energized components.

- Exposure to hazardous materials: Handling of conveyor contents, such as chemicals or hazardous waste.

5. What are the safety protocols for operating a conveyor system?

- Never operate the conveyor without proper training and authorization.

- Ensure that all guards and safety switches are in place and functioning correctly.

- Inspect the conveyor system before each use for any defects or hazards.

- Keep clear of all moving parts and wear appropriate personal protective equipment (PPE).

6. How do you adjust the tension on a conveyor belt?

- Use belt tension gauges to measure the belt tension at designated points.

- Adjust the tension by tightening or loosening the take-up pulleys.

- Follow the manufacturer’s specifications for the recommended belt tension range.

7. Explain the importance of aligning belt tracking systems.

- Prevents the belt from rubbing against the conveyor frame or components.

- Reduces wear and tear on the belt and other conveyor parts.

- Ensures smooth and efficient operation of the conveyor system.

8. Describe the different types of conveyor controls and their applications.

- Local Control Panel: Allows operators to start, stop, and adjust the conveyor from a nearby location.

- Remote Control Panel: Enables control of the conveyor from a distant location.

- PLC-Based Control System: Provides advanced features such as programming, monitoring, and diagnostics.

9. What are the common problems encountered in conveyor systems and how do you resolve them?

- Belt Misalignment: Adjust belt tracking systems and ensure proper tension.

- Roller Damage: Replace or repair damaged rollers.

- Bearing Failure: Replace worn or damaged bearings.

- Motor Overheating: Inspect and repair the motor or electrical system.

10. Explain the principles of conveyor safety switches and their function in protecting operators.

- Pull Cord Switches: Detect if an operator or object falls into the conveyor area.

- Proximity Sensors: Prevent access to hazardous areas around the conveyor.

- Emergency Stop Buttons: Allow operators to quickly shut down the conveyor in case of an emergency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conveyor Loader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conveyor Loader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conveyor Loaders are responsible for maintaining a smooth flow of materials along conveyor systems in a variety of industrial settings. Their primary duties include:

1. Loading and Unloading Materials

Manually or using automated equipment, they load and unload materials onto and off conveyor belts, ensuring that materials are positioned correctly for efficient transportation.

- Operate loading and unloading equipment, such as forklifts, cranes, and hoists.

- Position materials on conveyor belts, ensuring they are aligned properly and do not obstruct flow.

2. Monitoring Conveyor Systems

They monitor conveyor systems, ensuring that materials are moving smoothly and that there are no blockages or malfunctions.

- Visually inspect conveyor belts, rollers, and other components for signs of wear or damage.

- Listen for unusual noises or vibrations that may indicate potential issues.

3. Maintaining Conveyor Systems

They perform basic maintenance tasks to keep conveyor systems running efficiently, including cleaning, lubricating, and adjusting components.

- Clean conveyor belts and components to remove debris and prevent blockages.

- Lubricate bearings and other moving parts to reduce friction and wear.

4. Troubleshooting and Repairing Conveyor Systems

When problems arise, they troubleshoot and repair conveyor systems to minimize downtime and ensure smooth operation.

- Diagnose common conveyor system malfunctions, such as belt misalignment, jammed materials, and electrical issues.

- Perform minor repairs, such as replacing worn parts and adjusting tension.

Interview Tips

To ace a Conveyor Loader interview, it’s crucial to demonstrate a solid understanding of the job responsibilities and showcase your relevant skills and experience:

1. Highlight Your Physical Abilities

Conveyor Loaders require good physical strength and endurance to perform their duties. Emphasize your ability to lift heavy objects, work in various positions, and stand for extended periods.

- Quantify your physical capabilities, such as maximum weight you can lift or hours you can stand continuously.

- Provide examples of previous jobs where you demonstrated your physical abilities, such as working in a warehouse or construction site.

2. Show Your Problem-Solving Skills

Conveyor Loaders often encounter problems with conveyor systems. Emphasize your ability to identify and solve problems quickly and efficiently.

- Describe specific situations where you solved problems related to conveyor systems or other machinery.

- Explain your thought process and the steps you took to resolve the issues.

3. Highlight Your Attention to Detail

Conveyor Loaders need to pay close attention to the movement of materials and the condition of conveyor systems. Demonstrate your ability to observe and identify potential issues.

- Provide examples of previous jobs where you were responsible for monitoring and maintaining equipment.

- Explain how you ensured accuracy and consistency in your work.

4. Express Your Willingness to Learn

Conveyor Loaders may need to work with different types of conveyor systems and materials. Express your eagerness to learn new things and adapt to different environments.

- Share examples of your willingness to learn new skills or technologies in previous roles.

- Ask questions about the specific conveyor systems and materials you will be working with.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Conveyor Loader, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Conveyor Loader positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.