Are you gearing up for a career in Conveyor Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Conveyor Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

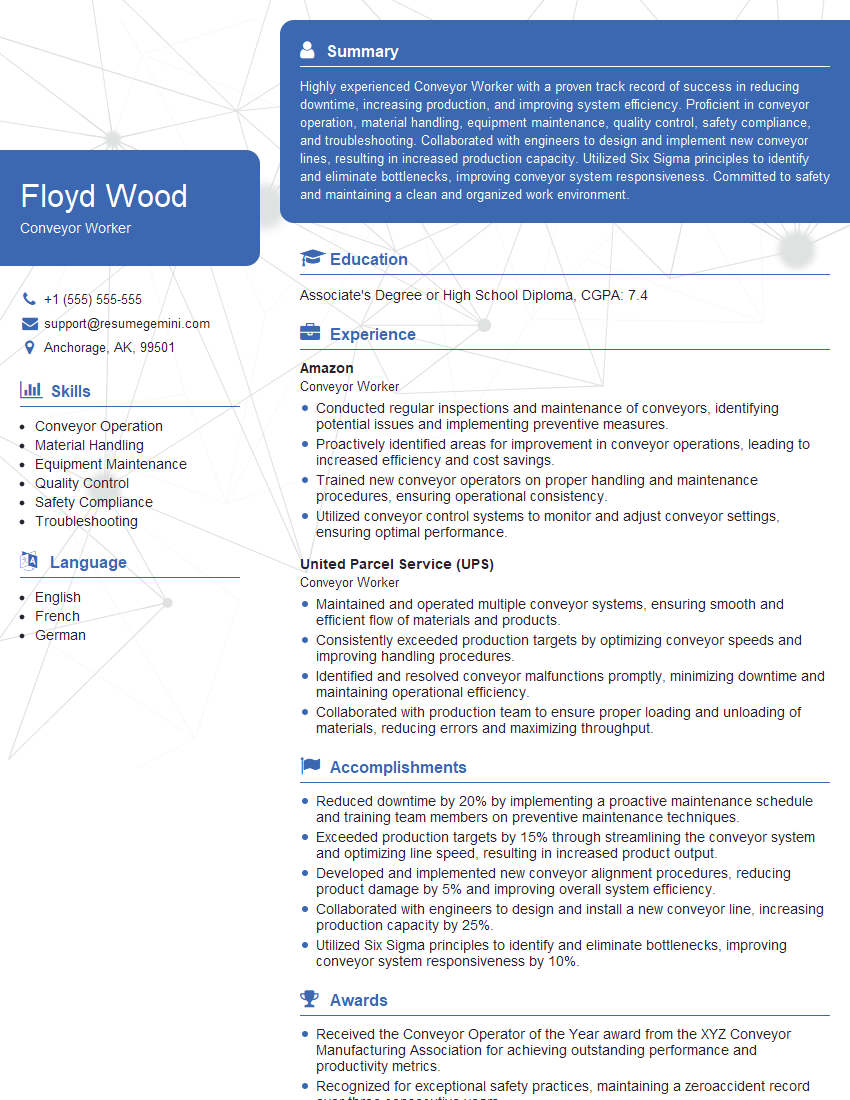

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Conveyor Worker

1. Can you describe the process of setting up and operating a conveyor system?

Here are the steps involved in setting up and operating a conveyor system:

- Inspect the conveyor system to ensure all components are in working order.

- Assemble the conveyor system according to the manufacturer’s instructions.

- Lubricate the conveyor system according to the manufacturer’s instructions.

- Load the conveyor system with the product that will be conveyed.

- Start the conveyor system and monitor its operation.

- Adjust the speed of the conveyor system as needed.

- Unload the conveyor system when the product has been conveyed to its destination.

- Clean the conveyor system according to the manufacturer’s instructions.

2. What are the different types of conveyors and when are they used?

Belt conveyors

- Best suited for conveying bulk materials over long distances.

- They are also used to convey heavy or abrasive materials.

Roller conveyors

- Best suited for conveying lightweight items over short distances.

- They are also used to convey items that are not easily damaged.

Chain conveyors

- Best suited for conveying heavy items over long distances.

- They are also used to convey items that are not easily damaged.

Screw conveyors

- Best suited for conveying bulk materials over long distances.

- They are also used to convey materials that are not easily damaged.

Pneumatic conveyors

- Best suited for conveying bulk materials over long distances.

- They are also used to convey materials that are not easily damaged.

3. What are the safety precautions that should be taken when working with a conveyor system?

- Never operate a conveyor system when it is not properly assembled.

- Never operate a conveyor system when it is not properly lubricated.

- Never load a conveyor system with more weight than it is rated for.

- Never start a conveyor system without first clearing the area in front of it.

- Never step onto a conveyor system while it is in operation.

- Never reach into a conveyor system while it is in operation.

- Never clean a conveyor system while it is in operation.

4. What are the common problems that can occur with a conveyor system and how can they be fixed?

- Problem: The conveyor belt is slipping. Solution: Tighten the conveyor belt.

- Problem: The conveyor belt is not tracking properly. Solution: Adjust the conveyor belt tracking.

- Problem: The conveyor system is making noise. Solution: Lubricate the conveyor system.

- Problem: The conveyor system is not moving. Solution: Check the power supply to the conveyor system.

5. What is the importance of preventive maintenance for a conveyor system?

- Preventive maintenance can help to identify and correct potential problems before they become major issues.

- Preventive maintenance can help to extend the life of the conveyor system.

- Preventive maintenance can help to reduce the cost of operating the conveyor system.

- Preventive maintenance can help to improve the safety of the conveyor system.

6. What are the different types of preventive maintenance that can be performed on a conveyor system?

- Visual inspections: These inspections can be performed daily or weekly to identify any potential problems.

- Lubrication: The conveyor system should be lubricated according to the manufacturer’s instructions.

- Belt tension checks: The conveyor belt should be checked for proper tension regularly.

- Tracking adjustments: The conveyor belt should be checked for proper tracking regularly.

- Electrical inspections: These inspections should be performed by a qualified electrician to ensure that the conveyor system is safe to operate.

7. How do you troubleshoot a conveyor system?

To troubleshoot a conveyor system, you can follow these steps:

- Identify the problem.

- Check the power supply to the conveyor system.

- Check the conveyor belt for damage.

- Check the conveyor system for any blockages.

- Check the conveyor system for any loose parts.

- Check the conveyor system for any leaks.

- If you are unable to identify the problem, contact a qualified technician.

8. What are the different types of sensors that can be used on a conveyor system?

- Photoelectric sensors: These sensors can be used to detect the presence or absence of an object.

- Proximity sensors: These sensors can be used to detect the presence or absence of an object without making physical contact with it.

- Limit switches: These sensors can be used to detect the position of an object.

- Encoders: These sensors can be used to measure the speed and position of an object.

9. How do you calibrate a sensor on a conveyor system?

To calibrate a sensor on a conveyor system, you can follow these steps:

- Identify the type of sensor that you are calibrating.

- Follow the manufacturer’s instructions for calibration.

- Use a calibration tool to calibrate the sensor.

- Verify the calibration of the sensor.

10. What is the importance of safety when working with a conveyor system?

- Conveyor systems can be dangerous if they are not operated properly.

- It is important to follow all safety precautions when working with a conveyor system.

- Never operate a conveyor system when it is not properly assembled.

- Never operate a conveyor system when it is not properly lubricated.

- Never load a conveyor system with more weight than it is rated for.

- Never start a conveyor system without first clearing the area in front of it.

- Never step onto a conveyor system while it is in operation.

- Never reach into a conveyor system while it is in operation.

- Never clean a conveyor system while it is in operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Conveyor Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Conveyor Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Conveyor Workers are responsible for a variety of vital tasks related to the smooth operation of conveyor systems in manufacturing and production facilities.

1. Monitoring and maintaining conveyors

Conveyor Workers are responsible for monitoring the performance of conveyors and conducting regular maintenance to ensure smooth operation. This includes inspecting components, lubricating parts, and making adjustments as needed.

- Inspecting conveyor belts, rollers, and other components for signs of wear or damage

- Lubricating conveyor chains, bearings, and other moving parts

- Adjusting conveyor speed, tension, and alignment to optimize performance

2. Loading and unloading materials

Conveyor Workers play an essential role in loading and unloading materials onto and from conveyors. This involves following designated procedures and ensuring that materials are handled safely and efficiently.

- Loading materials onto conveyors, including pallets, boxes, and individual items

- Unloading materials from conveyors at designated locations

- Ensuring materials are loaded and unloaded safely and securely

3. Clearing jams and blockages

Conveyor Workers are responsible for promptly clearing jams and blockages that may occur on conveyors. This requires identifying the cause of the blockage and taking appropriate measures to remove obstacles.

- Identifying and clearing jams or blockages on conveyor belts

- Using tools and equipment to remove foreign objects or debris

- Restarting conveyors after blockages have been cleared

4. Following safety procedures

Conveyor Workers must adhere strictly to safety procedures and regulations to ensure their own safety and the safety of others in the workplace. This includes wearing appropriate personal protective equipment (PPE), following lockout-tagout procedures, and reporting any potential hazards.

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs

- Following lockout-tagout procedures to ensure machinery is safely turned off before performing maintenance or repairs

- Reporting any potential hazards or unsafe conditions to supervisors

Interview Tips

Preparing thoroughly for a Conveyor Worker interview can significantly increase your chances of success. Here are some tips and hacks to help you ace your interview:

1. Research the company and the position

Before the interview, research the company you are applying to, including its mission, values, products or services, and industry standing. This knowledge will allow you to tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people in your network who work in the industry

2. Highlight relevant skills and experience

In your resume and cover letter, highlight your skills and experience that are most relevant to the Conveyor Worker position. Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your contributions.

- Emphasize your experience in monitoring and maintaining conveyors

- Describe your skills in loading and unloading materials safely and efficiently

- Mention any experience you have in clearing jams and blockages

3. Practice answering common interview questions

Anticipate common interview questions and prepare thoughtful answers that showcase your skills and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Tell me about a time you had to troubleshoot and resolve a problem with a conveyor system.

- Describe your experience in working safely in a manufacturing environment.

- How do you stay motivated and focused when performing repetitive tasks?

4. Dress professionally and arrive on time

First impressions matter, so dress professionally for your interview. Arrive on time, and if possible, arrive a few minutes early to demonstrate your punctuality and respect for the interviewer’s time.

- Wear appropriate business attire, such as a suit or dress pants and a button-down shirt

- Make sure your clothes are clean and pressed

- Arrive at the interview location on time, or even a few minutes early

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Conveyor Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.