Are you gearing up for an interview for a Cooling Pipe Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cooling Pipe Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

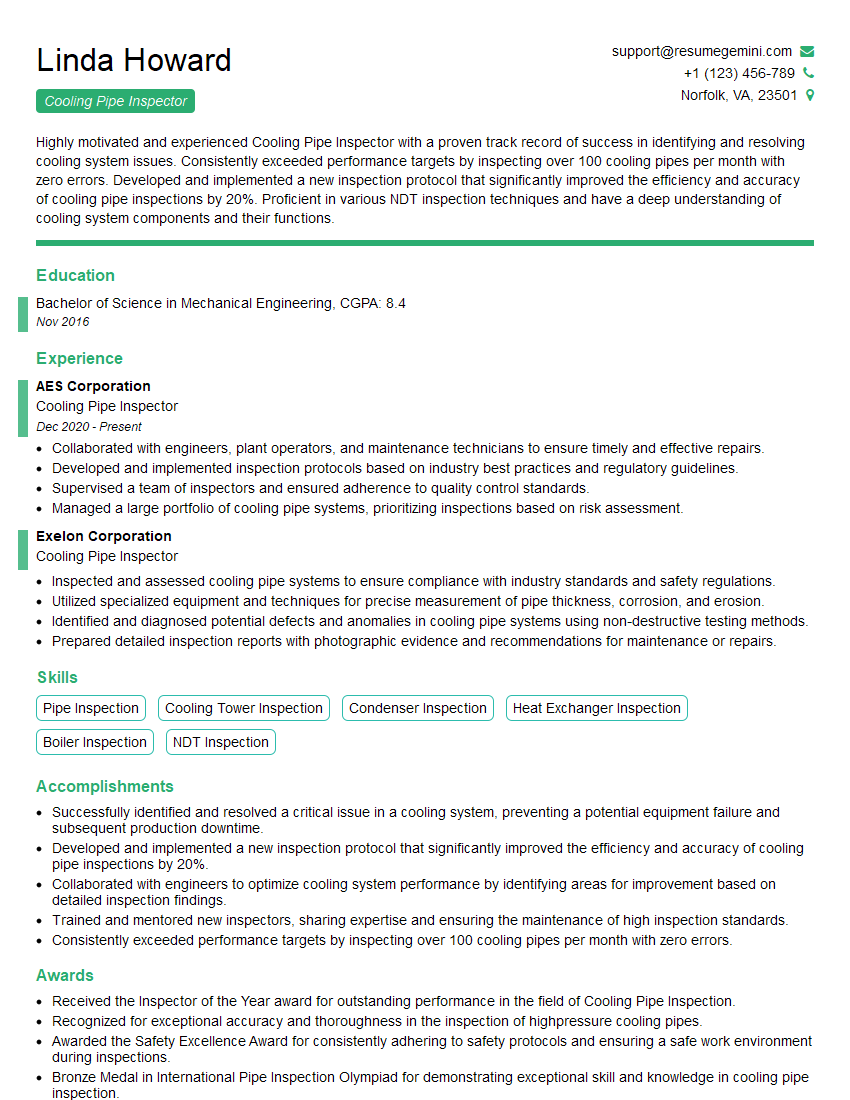

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cooling Pipe Inspector

1. What are the key responsibilities of a Cooling Pipe Inspector?

- Inspect cooling pipes for corrosion, leaks, and other defects.

- Ensure that cooling pipes meet the required standards and codes.

- Identify and report potential hazards to personnel and equipment.

2. Explain the different types of cooling pipe inspection methods

Ultrasonic Testing (UT)

- Uses high-frequency sound waves to detect flaws in the pipe.

- Can be used to inspect both internal and external surfaces of the pipe.

Radiographic Testing (RT)

- Uses X-rays or gamma rays to produce images of the internal structure of the pipe.

- Can be used to detect flaws, such as cracks or voids, that are not visible to the naked eye.

Magnetic Particle Testing (MT)

- Uses magnetic fields to detect surface cracks in the pipe.

- Is a quick and relatively inexpensive method of inspection.

3. What are the common causes of cooling pipe failure?

- Corrosion

- Erosion

- Thermal stress

- Mechanical stress

4. How do you interpret the results of a cooling pipe inspection?

- Identify the type and location of any defects.

- Determine the severity of the defects.

- Recommend appropriate corrective actions.

5. What are the safety precautions that should be taken when inspecting cooling pipes?

- Wear appropriate PPE, including hard hat, safety glasses, and gloves.

- Be aware of the location of electrical hazards.

- Do not enter confined spaces without proper training and equipment.

6. What are the latest trends in cooling pipe inspection technology?

- The use of drones for remote inspection.

- The development of more advanced non-destructive testing (NDT) methods.

- The use of artificial intelligence (AI) to analyze inspection data.

7. What are the challenges of cooling pipe inspection?

- The inaccessibility of some pipes.

- The presence of hazardous materials.

- The time constraints for inspections.

8. How do you stay up-to-date on the latest cooling pipe inspection techniques?

- Attend industry conferences and workshops.

- Read trade publications.

- Complete online training courses.

9. What is your experience with using NDT equipment?

- Describe the specific NDT equipment you have used, such as ultrasonic flaw detectors, radiographic equipment, and magnetic particle inspection equipment.

- Explain how you have used these techniques to detect and evaluate defects in cooling pipes.

10. What is your understanding of the ASME B31.3 code?

- Explain the purpose and scope of the ASME B31.3 code.

- Describe the key requirements of the code for cooling pipe inspection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cooling Pipe Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cooling Pipe Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cooling Pipe Inspectors are responsible for ensuring the integrity of cooling pipes in industrial and commercial settings. Their key responsibilities include:

1. Inspecting Cooling Pipes

Inspecting cooling pipes for any signs of damage, corrosion, or leaks. This may involve using specialized equipment such as ultrasonic testing, radiography, or visual inspection.

2. Evaluating Pipe Conditions

Evaluating the condition of cooling pipes and assessing their remaining lifespan. This may involve considering factors such as the age of the pipes, the operating conditions, and the materials used in their construction.

3. Monitoring Pipe Systems

Monitoring cooling pipe systems to ensure they are operating efficiently and safely. This may involve collecting data, analyzing trends, and identifying any potential issues.

4. Preparing Reports

Preparing detailed reports on the condition of cooling pipes and making recommendations for any necessary repairs or replacements. These reports may be used by management to make informed decisions about the maintenance and operation of the cooling system.

Interview Tips

Preparing for an interview for a Cooling Pipe Inspector position requires careful planning and a well-thought-out approach. Here are a few tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take some time to research the company and the industry. This will help you understand their business goals and the specific challenges they face related to cooling pipe inspection.

2. Practice Answering Common Interview Questions

Practice answering common interview questions such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” Tailor your answers to the specific job requirements and the company’s needs.

3. Prepare Questions to Ask

Asking insightful questions during the interview shows that you are engaged and interested in the position. Prepare thoughtful questions about the company’s cooling pipe inspection procedures, their quality control measures, and their plans for future growth.

4. Highlight Your Relevant Experience

In your interview, make sure to highlight your relevant experience and skills. This could include your experience in conducting cooling pipe inspections, analyzing pipe conditions, or preparing inspection reports.

5. Be Professional and Enthusiastic

Throughout the interview, maintain a professional and enthusiastic demeanor. Show the interviewer that you are genuinely interested in the position and that you have the necessary skills and qualifications to excel in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cooling Pipe Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cooling Pipe Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.