Feeling lost in a sea of interview questions? Landed that dream interview for Coordinate Measuring Equipment Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coordinate Measuring Equipment Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

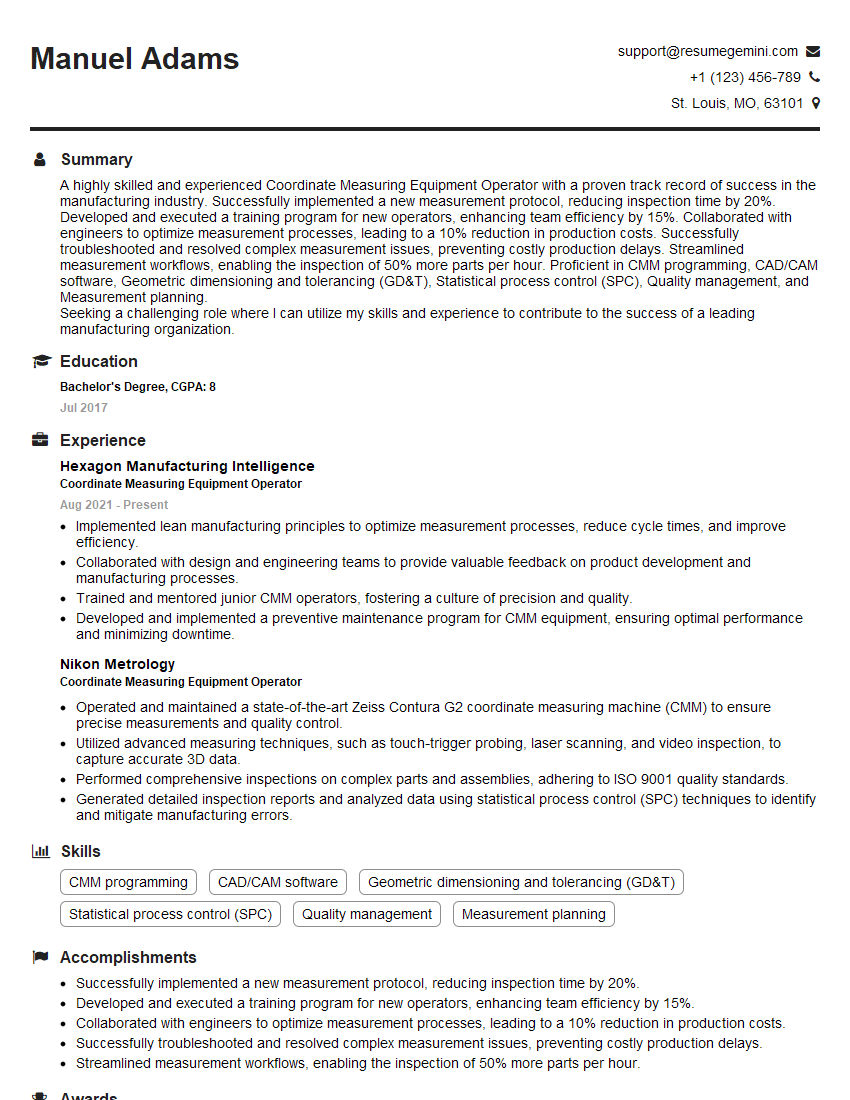

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coordinate Measuring Equipment Operator

1. What are the typical applications of a Coordinate Measuring Machine (CMM)?

- Measuring the dimensions and geometry of physical objects

- Inspecting parts for quality control

- Reverse engineering

- Creating 3D models

2. What are the different types of CMMs?

Contact CMMs

- Touch-trigger probes

- Scanning probes

Non-contact CMMs

- Laser scanners

- Vision systems

3. What are the key specifications to consider when selecting a CMM?

- Measuring range

- Accuracy

- Repeatability

- Software capabilities

- Probe options

4. How do you calibrate a CMM?

- Using a certified calibration artifact

- Following the manufacturer’s calibration procedure

- Verifying the accuracy of the CMM against known measurements

5. What are the common errors that can occur when using a CMM?

- Probe deflection

- Temperature variations

- Operator error

- Software glitches

6. How do you troubleshoot a CMM when it is not functioning properly?

- Check the power supply and connections

- Inspect the probe and stylus for damage

- Review the software settings

- Contact the manufacturer for technical support

7. What are the advantages of using a CMM over traditional measurement methods?

- Higher accuracy and repeatability

- Faster measurement times

- Ability to measure complex geometries

- Data can be stored and analyzed digitally

8. What are the challenges of working as a CMM operator?

- Requiring extensive training

- Demanding high levels of attention and accuracy

- Working with heavy and potentially dangerous equipment

9. How do you stay up-to-date on the latest CMM technology and best practices?

- Attending industry conferences and trade shows

- Reading technical journals and articles

- Taking online courses and webinars

- Networking with other CMM operators

10. What is your experience with programming and operating CMM software?

- Describe the different software platforms you have used

- Explain your proficiency in creating and executing measurement routines

- Discuss your ability to troubleshoot software errors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coordinate Measuring Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coordinate Measuring Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coordinate Measuring Equipment (CME) Operators are responsible for operating and maintaining CME machines used to measure the dimensions of manufactured parts. These machines use a probe to touch the surface of a part and collect data on its size and shape. CME Operators must be able to interpret the data collected by the machine and use it to create accurate reports.

1. Operate CME machines

CME Operators must be able to operate CME machines safely and efficiently. This includes setting up the machine, loading and unloading parts, and running the measurement program.

- Set up the CME machine according to the specifications of the part being measured.

- Load and unload parts onto the CME machine.

- Run the measurement program and collect data on the part’s size and shape.

- Interpret the data collected by the CME machine and create accurate reports.

2. Maintain CME machines

CME Operators must be able to maintain CME machines in good working order. This includes cleaning the machine, lubricating moving parts, and calibrating the machine regularly.

- Clean the CME machine according to the manufacturer’s instructions.

- Lubricate moving parts on the CME machine according to the manufacturer’s instructions.

- Calibrate the CME machine according to the manufacturer’s instructions.

- Troubleshoot and repair minor problems with the CME machine.

3. Inspect parts

CME Operators must be able to inspect parts to ensure that they meet specifications. This includes visually inspecting the part for defects and using the CME machine to measure the part’s dimensions.

- Visually inspect parts for defects such as scratches, dents, and cracks.

- Use the CME machine to measure the part’s dimensions and compare them to the specifications.

- Accept or reject parts based on the inspection results.

4. Work with other team members

CME Operators must be able to work with other team members to ensure that parts are manufactured to specifications. This includes communicating with engineers, machinists, and quality control inspectors.

- Communicate with engineers to clarify specifications for parts.

- Work with machinists to ensure that parts are manufactured to specifications.

- Work with quality control inspectors to ensure that parts meet specifications.

Interview Preparation Tips For Coordinate Measuring Equipment Operator

To help candidates ace their interview for a Coordinate Measuring Equipment Operator position, here are some tips and hacks:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a CME Operator.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get insights into the company culture.

- Talk to people you know who work for the company to get their impressions.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked in an interview for a CME Operator position. By practicing answering these questions ahead of time, you will be able to deliver more confident and polished responses during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with CME machines?

- How do you maintain and calibrate CME machines?

- How do you inspect parts to ensure that they meet specifications?

- How do you work with other team members?

3. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you have taken the time to prepare for the interview. It also gives you an opportunity to learn more about the company and the position.

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company’s culture like?

- What is the most important thing you are looking for in a CME Operator?

4. Dress professionally and arrive on time

Making a good first impression is important, so dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location 10-15 minutes early to give yourself time to relax and prepare.

5. Be confident and enthusiastic

Confidence and enthusiasm are contagious, so make sure to project these qualities during your interview. This will help you make a positive impression on the interviewer and show that you are excited about the opportunity to work for the company.

- Maintain eye contact with the interviewer and speak clearly and confidently.

- Smile and be enthusiastic about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coordinate Measuring Equipment Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.