Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Coordinate Measuring Machine Operator (CMM Operator) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Coordinate Measuring Machine Operator (CMM Operator) so you can tailor your answers to impress potential employers.

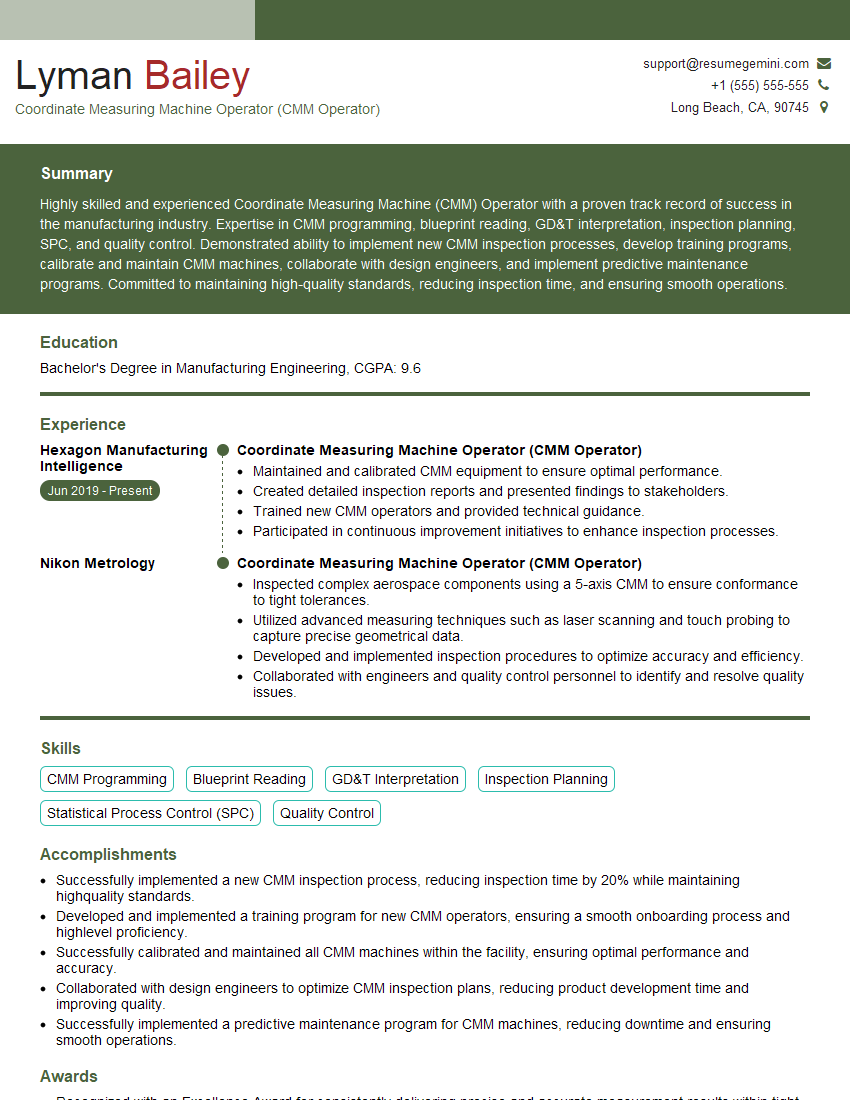

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coordinate Measuring Machine Operator (CMM Operator)

1. How do you ensure the accuracy of your measurements on a CMM?

To ensure the accuracy of my measurements on a CMM, I follow a rigorous process that includes:

- Regular calibration of the CMM using traceable standards

- Using high-quality probes and fixtures to minimize measurement errors

- Careful part fixturing to prevent movement during measurement

- Employing appropriate measurement techniques to minimize operator influence

- Documenting all measurement parameters and procedures to ensure consistency

2. What types of CMM software are you familiar with?

I am proficient in a variety of CMM software packages, including:

PC-DMIS

- Creating and editing measurement programs

- Performing manual and automated inspections

- Analyzing and reporting measurement data

Calypso

- Programming and operating CMMs using Calypso software

- Creating and managing measurement routines

- Generating inspection reports and data

3. Can you describe the different types of probes used on a CMM?

The main types of probes used on a CMM include:

- Touch-trigger probes: These probes make contact with the workpiece surface to measure its position. They are typically used for high-accuracy measurements.

- Scanning probes: These probes move continuously over the workpiece surface, collecting a large number of data points. They are typically used for fast, non-contact measurements.

- Optical probes: These probes use a laser or other optical technology to measure the workpiece surface. They are typically used for non-contact measurements of complex surfaces.

4. What is the difference between a DCC and a CNC CMM?

A DCC (Direct Computer Control) CMM is controlled directly by a computer, while a CNC (Computer Numerical Control) CMM is controlled by a dedicated controller. DCC CMMs are more flexible and versatile, as they can be programmed to perform a wider range of measurements. CNC CMMs are typically faster and more efficient for repetitive measurements.

5. What are the key factors to consider when selecting a CMM for a particular application?

When selecting a CMM for a particular application, the key factors to consider include:

- The size and complexity of the workpieces to be measured

- The required accuracy and precision of the measurements

- The speed and efficiency required for the inspection process

- The available budget for the CMM

6. How do you handle the calibration of a CMM?

The calibration of a CMM is a critical process that ensures the accuracy of the measurements. I typically follow the following steps:

- Clean the CMM and all its components.

- Check the CMM’s software and firmware for updates.

- Use a traceable calibration artifact to calibrate the CMM’s axes.

- Verify the calibration results and make any necessary adjustments.

- Document the calibration procedure and results.

7. What are some of the common maintenance tasks that you perform on a CMM?

Regular maintenance is essential to ensure the accuracy and reliability of a CMM. Some of the common maintenance tasks that I perform include:

- Cleaning the CMM and its components

- Lubricating the CMM’s moving parts

- Checking the CMM’s cables and connections

- Inspecting the CMM’s probe and stylus

- Calibrating the CMM

8. How do you troubleshoot a CMM?

Troubleshooting a CMM involves identifying and resolving any issues that may be affecting its performance. I typically follow the following steps:

- Identify the symptoms of the problem.

- Check the CMM’s software and firmware for errors.

- Inspect the CMM’s hardware for any loose connections or damaged components.

- Calibrate the CMM to ensure its accuracy.

- Test the CMM using a known-good workpiece.

9. What are some of the quality control procedures that you follow when using a CMM?

Quality control procedures are essential to ensure the accuracy and reliability of CMM measurements. Some of the procedures that I follow include:

- Using calibrated CMMs and probes

- Following established measurement procedures

- Verifying measurements with other methods

- Documenting all measurement data

- Participating in regular training and certification programs

10. What are the challenges of working as a CMM Operator?

Some of the challenges of working as a CMM Operator include:

- Maintaining the accuracy and reliability of CMM equipment

- Interpreting complex measurement data

- Troubleshooting and resolving CMM problems

- Working in a demanding and fast-paced environment

- Keeping up with the latest CMM technology and techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coordinate Measuring Machine Operator (CMM Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coordinate Measuring Machine Operator (CMM Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Coordinate Measuring Machine (CMM) operator is accountable for coordinating and utilizing highly specialized equipment to measure the dimensions, shapes and features of components and products. Let’s explore their key job responsibilities:

1. CMM Operation

CMM operators are entrusted with planning and executing measurement processes using CMM equipment. They ensure the precise operation of the CMM, selecting appropriate probes, fixtures and measurement strategies.

2. Programming

These professionals are proficient in programming CMMs to perform automated measurement routines. They interpret engineering drawings and specifications to create programs that guide the machine’s movements and data collection.

3. Data Analysis and Reporting

CMM operators analyze the measurement data obtained from the CMM. They evaluate dimensional accuracy, generate reports, and communicate the results to engineering and production teams.

4. Quality Control and Inspection

They play a crucial role in quality control by inspecting parts and products against predefined specifications. They identify and document any deviations from the specified tolerances, ensuring adherence to quality standards.

5. Collaboration and Communication

CMM operators collaborate closely with engineers, quality control personnel, and production staff to resolve discrepancies, improve processes, and ensure the efficiency of measurement operations.

Interview Tips

Preparing for an interview as a CMM Operator requires a combination of technical expertise and effective communication skills. Here are some valuable tips to help you ace the interview:

1. Highlight Your Technical Skills

Emphasize your proficiency in CMM operation, programming, and data analysis. Provide specific examples of projects where you successfully utilized CMM equipment and achieved accurate measurement results.

2. Showcase Your Attention to Detail

As a CMM operator, meticulous attention to detail is crucial. During the interview, demonstrate your ability to identify and analyze even the smallest deviations in measurements.

3. Prepare for Industry Knowledge Questions

Research the industry and be prepared to discuss current trends and best practices in CMM operation. Show that you are knowledgeable about the latest software and technologies used in the field.

4. Practice Communicating Effectively

Be prepared to articulate your findings and recommendations clearly and concisely. Your ability to communicate technical information effectively will be highly valued by potential employers.

5. Prepare Relevant Questions

Asking thoughtful questions at the end of the interview shows your genuine interest in the role and company. Prepare questions that demonstrate your understanding of the industry and your desire to contribute.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coordinate Measuring Machine Operator (CMM Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!