Are you gearing up for an interview for a Coordinate Measuring Machine Technician (CMM Technician) position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coordinate Measuring Machine Technician (CMM Technician) and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

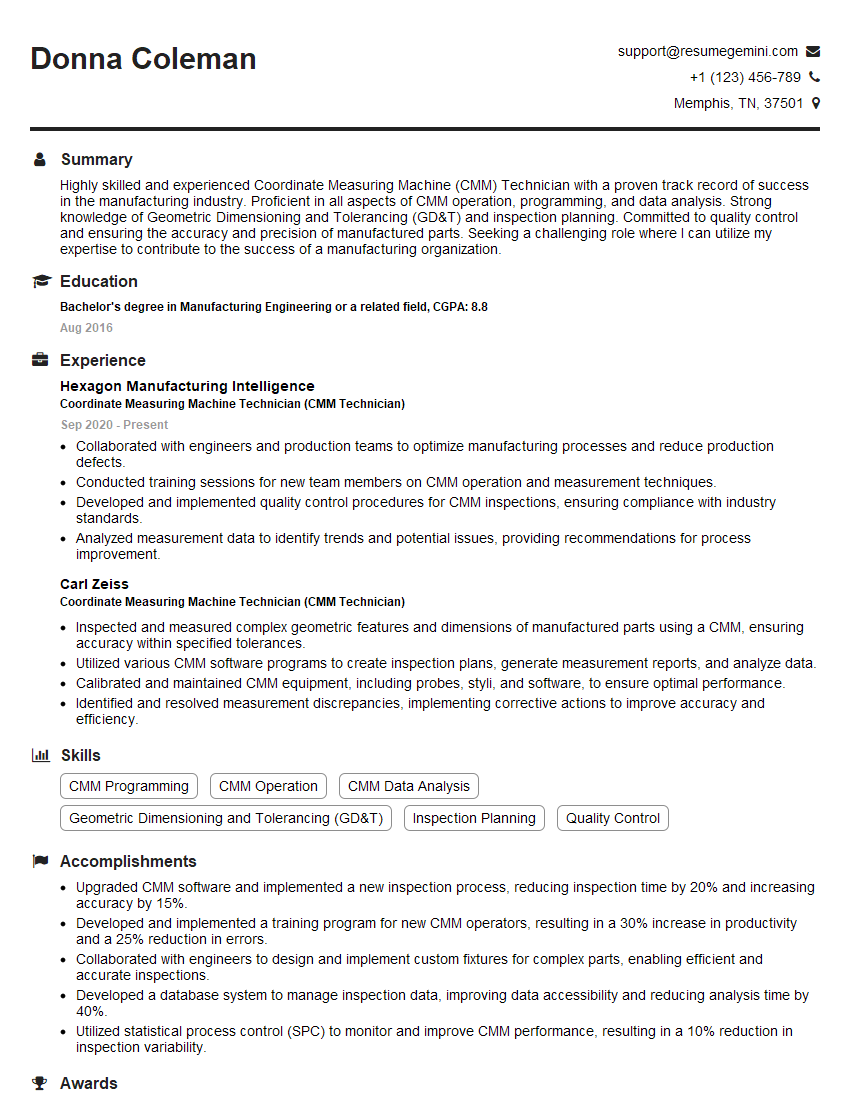

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coordinate Measuring Machine Technician (CMM Technician)

1. What is the difference between a manual and a CNC CMM?

A manual CMM is operated by a human operator, while a CNC CMM is controlled by a computer. Manual CMMs are typically used for simple measurements, while CNC CMMs are used for more complex measurements. CNC CMMs are more accurate and repeatable than manual CMMs, and they can be used to measure a wider range of parts.

- Manual CMMs are operated by a human operator.

- CNC CMMs are controlled by a computer.

- CNC CMMs are more accurate and repeatable than manual CMMs.

- CNC CMMs can be used to measure a wider range of parts.

2. What are the different types of CMM probes?

Contact probes

- Touch trigger probes

- Scanning probes

Non-contact probes

- Laser scanners

- Optical scanners

3. What are the advantages and disadvantages of using a touch trigger probe?

-

Advantages:

- High accuracy and repeatability

- Can be used to measure a wide range of materials

- Relatively low cost Disadvantages:

- Can damage soft or delicate parts

- Slow measurement speed

4. What are the advantages and disadvantages of using a laser scanner?

-

Advantages:

- Non-contact measurement, so no damage to parts

- Fast measurement speed

- Can be used to measure complex shapes Disadvantages:

- Lower accuracy and repeatability than touch trigger probes

- Can be affected by environmental factors, such as dust and vibration

5. What is the purpose of a CMM calibration?

To ensure that the CMM is measuring parts accurately. Calibration is performed by measuring a known standard and comparing the results to the expected values. If the results are within tolerance, the CMM is considered to be calibrated.

- To ensure that the CMM is measuring parts accurately

- Calibration is performed by measuring a known standard and comparing the results to the expected values

6. What are the different types of CMM software?

- Metrology software

- CAD/CAM software

- Statistical software

7. What are the key features of a good CMM software package?

- User-friendly interface

- Powerful measurement capabilities

- Comprehensive reporting features

- Good technical support

8. What are the different ways to program a CMM?

- Manual programming

- Conversational programming

- CAD/CAM programming

9. What are the advantages and disadvantages of manual programming?

-

Advantages:

- Full control over the measurement process

- Can be used to measure complex shapes

- No need for CAD/CAM software Disadvantages:

- Time-consuming

- Prone to errors

10. What are the advantages and disadvantages of CAD/CAM programming?

-

Advantages:

- Fast and efficient

- Reduced errors

- Can be used to measure complex shapes Disadvantages:

- Requires CAD/CAM software

- Less control over the measurement process

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coordinate Measuring Machine Technician (CMM Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coordinate Measuring Machine Technician (CMM Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coordinate Measuring Machine Technicians (CMM Technicians) play a crucial role in ensuring the accuracy and precision of manufactured parts and products.

1. CMM Operation and Programming

Operate and program CMMs to measure the size, shape, and other geometric features of parts and products.

- Plan and execute measurement routines using advanced software and programming languages.

- Calibrate and maintain CMM equipment to ensure accuracy and reliability.

2. Data Analysis and Interpretation

Analyze measurement data and compare it to specifications to identify deviations and non-conformances.

- Create detailed inspection reports and records for quality control and documentation purposes.

- Troubleshoot and resolve measurement issues to ensure accurate and reliable data.

3. Part Inspection and Verification

Inspect parts and products using CMMs to ensure they meet design specifications and quality standards.

- Conduct first article inspections to verify the accuracy of new parts and processes.

- Identify and document any defects or non-conformances in parts and products.

4. Quality Management and Improvement

Contribute to the improvement of quality processes by identifying areas for improvement and implementing corrective actions.

- Participate in quality control meetings and provide feedback on inspection results.

- Maintain a clean and organized work area to ensure accurate measurements and prevent contamination.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some practical tips to help you ace your CMM Technician interview:

1. Research the Company and Position

Show the interviewers that you have taken the time to learn about the company and the specific role you are applying for. Familiarize yourself with their products, services, and industry reputation.

- Visit the company website to gather information about their history, culture, and recent developments.

- Read industry news and articles to gain insights into the company’s position within the market.

2. Practice Your Technical Skills

A CMM Technician interview will likely involve technical questions related to CMM operation, programming, and data analysis. Practice these skills beforehand to demonstrate your proficiency.

- Review your knowledge of CMM software, programming languages, and measurement techniques.

- Prepare examples of complex measurement projects you have successfully completed in the past.

3. Highlight Your Relevant Experience

Emphasize your previous experience in CMM operation and inspection. Quantify your accomplishments using specific examples and metrics.

- Provide details about the types of parts and products you have inspected using CMMs.

- Discuss any quality improvement initiatives you have implemented or contributed to.

4. Demonstrate Your Problem-Solving Abilities

CMM Technicians often encounter challenges and deviations during inspections. Prepare examples of how you have effectively solved problems and identified solutions.

- Describe a situation where you identified a non-conformance and worked with engineers to determine its root cause.

- Explain how you implemented corrective actions to prevent similar issues from occurring in the future.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coordinate Measuring Machine Technician (CMM Technician) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.