Feeling lost in a sea of interview questions? Landed that dream interview for Coping Machine Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Coping Machine Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

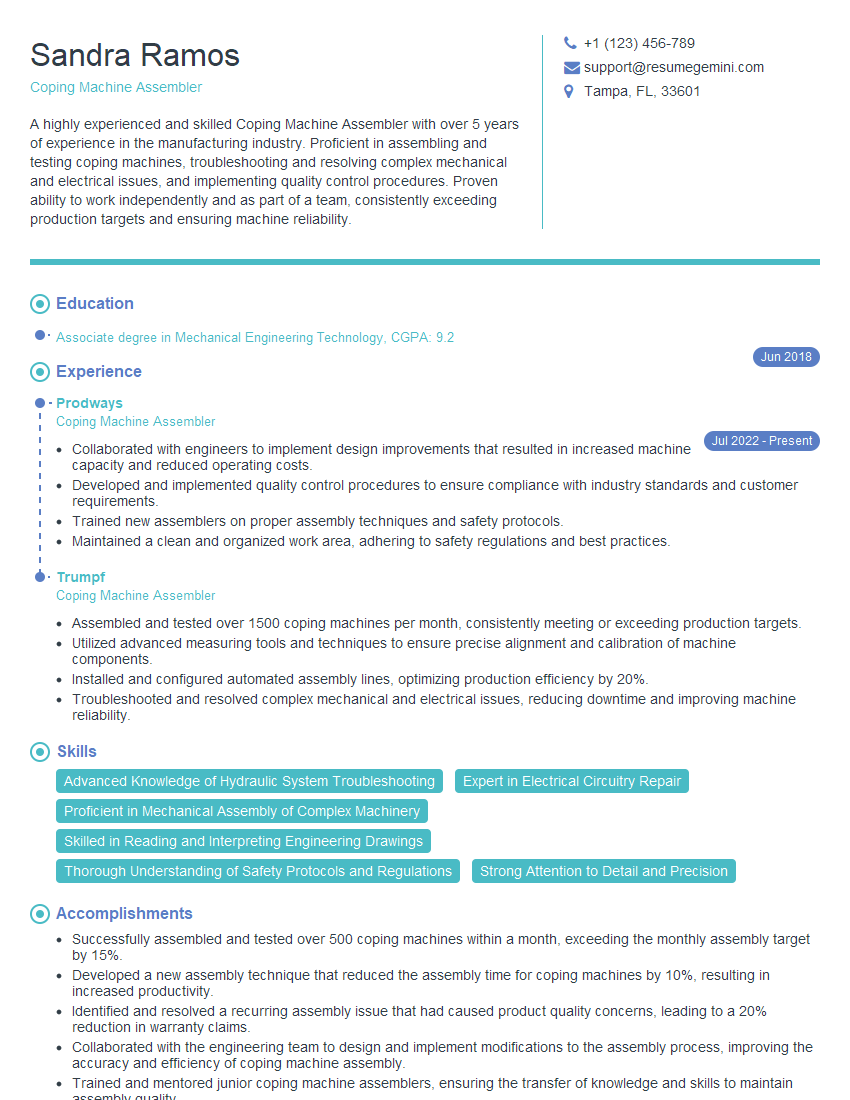

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coping Machine Assembler

1. Explain the process of assembling a coping machine.

In the assembly of a coping machine, I follow a meticulous process to ensure accuracy and precision. It involves:

- Unpacking and inspecting all components to verify their completeness and condition.

- Establishing a clean and organized workspace to minimize errors.

- Positioning the machine base and securing it firmly.

- Installing the motor and ensuring its proper alignment.

- Assembling the blade assembly, including mounting the blade and adjusting its tension.

- Attaching the table and fence, ensuring proper alignment and clamping.

- Wiring and connecting all electrical components according to the manufacturer’s instructions.

- Thoroughly testing the machine’s functionality and making any necessary adjustments.

2. How do you maintain and troubleshoot common issues with a coping machine?

Preventive Maintenance:

- Regularly clean and lubricate all moving parts.

- Check and adjust blade tension to ensure optimal cutting performance.

- Inspect electrical connections and wiring for any signs of damage or wear.

Troubleshooting:

- If the machine is not cutting properly, check the blade sharpness, tension, and alignment.

- Difficulty in feeding material often indicates improper table or fence alignment.

- Electrical issues can be identified by checking for loose connections, damaged wires, or faulty switches.

3. What safety precautions should be taken when operating a coping machine?

To ensure safety while operating a coping machine, I prioritize the following precautions:

- Always wear appropriate safety gear, including eye protection and gloves.

- Securely clamp the workpiece to the table before starting the machine.

- Keep hands away from the blade and moving parts.

- Never attempt to adjust or repair the machine while it is running.

- Unplug the machine before performing any maintenance or repairs.

4. How do you determine the correct blade for different cutting applications?

Selecting the appropriate blade for a coping machine depends on the material being cut and the desired cut quality:

- For smooth, clean cuts in wood, I use high-speed steel (HSS) blades with a high tooth count.

- For harder materials like metal or plastics, I opt for carbide-tipped blades with fewer teeth for increased durability.

- For intricate cuts or curves, I use specialized blades designed for coping.

5. What is the significance of proper blade alignment in a coping machine?

Correct blade alignment is crucial for achieving precise and efficient cuts. It ensures:

- Cutting Accuracy: Misaligned blades can produce skewed or uneven cuts.

- Blade Life: Improper alignment can cause premature blade wear and tear.

- Machine Longevity: Maintaining proper alignment reduces stress on the machine’s components, extending its lifespan.

6. How do you ensure the machine is level and properly calibrated?

To guarantee accurate cuts, I follow these steps:

- Use a spirit level to verify that the machine base is level on all sides.

- Calibrate the table and fence using a precision measuring tool to ensure they are perfectly square to the blade.

- Adjust the blade height to match the thickness of the material being cut.

7. How do you maintain the cleanliness and accuracy of a coping machine’s fence?

Maintaining a clean and precise fence is essential:

- Cleaning: Regularly remove sawdust and debris to ensure smooth movement.

- Inspection: Check for any damage or warping that could affect cutting accuracy.

- Calibration: Adjust the fence to ensure it is parallel to the blade and perpendicular to the table.

8. What techniques do you employ to achieve intricate and precise cuts with a coping machine?

For intricate cuts, I use the following techniques:

- Featherboarding: Using a thin, auxiliary piece to support the workpiece and prevent it from twisting or vibrating.

- Coping Sled: A specialized jig that allows for precise angle and compound cuts.

- Compass Cutting: Utilizing a compass or circle cutter attachment to create curved cuts.

9. How do you handle and store coping machine blades safely?

To ensure safety and longevity of the blades:

- Handling: Wear gloves and use a blade guard to prevent cuts or injuries.

- Storage: Store blades in a dry, cool place, protected from moisture and corrosion.

- Disposing: Properly dispose of dull or damaged blades according to manufacturer’s guidelines.

10. Explain the importance of adhering to manufacturer’s instructions and safety guidelines while operating a coping machine.

Following manufacturer’s instructions and safety guidelines is paramount:

- Safety: They provide specific instructions to prevent accidents and injuries.

- Machine Performance: Proper use and maintenance ensure optimal machine performance.

- Warranty: Adhering to guidelines upholds warranty coverage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coping Machine Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coping Machine Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coping Machine Assemblers play a crucial role in manufacturing operations, ensuring the assembly and maintenance of coping machines. Their key responsibilities include:

1. Machine Assembly and Installation

Coping Machine Assemblers are responsible for assembling and installing coping machines from individual components. They interpret technical blueprints, follow assembly instructions, and use appropriate tools and techniques to connect various machine parts.

- Assemble coping machines according to specifications, ensuring all components are properly aligned and secured

- Install and adjust machine parts, such as saw blades, guides, and tables, to meet performance requirements

2. Machine Inspection and Testing

To ensure the proper functioning of coping machines, Assemblers conduct thorough inspections and tests after assembly. They verify the machine’s accuracy, precision, and safety before it is released for production.

- Inspect completed machines to check for defects, misalignments, or loose components

- Conduct performance tests to assess the machine’s cutting capabilities, speed, and accuracy

3. Machine Maintenance and Repair

Coping Machine Assemblers are responsible for maintaining and repairing coping machines to ensure their ongoing operation. They perform regular inspections, identify potential issues, and take necessary actions to resolve them.

- Lubricate and clean coping machines to prevent wear and tear

- Repair or replace faulty components, such as bearings, gears, or electrical parts

4. Process Improvement and Troubleshooting

Assemblers continuously monitor the performance of coping machines to identify areas for improvement. They analyze production data, troubleshoot mechanical issues, and propose modifications to enhance efficiency or accuracy.

- Identify bottlenecks in the assembly or production process and propose solutions

- Troubleshoot mechanical failures, diagnose issues, and recommend corrective actions

Interview Tips

To prepare effectively for a Coping Machine Assembler interview, candidates should focus on demonstrating their technical expertise, problem-solving abilities, and attention to detail.

1. Research the Company and Industry

Gather information about the company’s products, manufacturing processes, and industry trends. This knowledge will showcase your interest in the position and industry.

- Visit the company website and study their products and services

- Read industry publications and attend industry events to stay informed

2. Highlight Relevant Skills and Experience

Prepare a clear and concise resume that emphasizes your assembly, inspection, and troubleshooting skills. Quantify your experience with specific examples of projects or achievements.

- Showcase your expertise in coping machine assembly and installation

- Demonstrate your ability to inspect and test machines for accuracy and precision

3. Practice Technical Questions

Study common technical questions that you may encounter in an interview. Practice answering these questions clearly and concisely, using specific examples from your work experience.

- Describe the process of assembling a coping machine

- How do you inspect a coping machine for accuracy and precision?

- Provide an example of a complex troubleshooting challenge you faced

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and company. Prepare a few insightful questions that reflect your knowledge of the industry.

- Inquire about the company’s growth plans or new product developments

- Ask about the company’s commitment to quality and customer satisfaction

5. Dress Professionally and Be Punctual

First impressions matter. Arrive on time for your interview and dress appropriately for the industry and position. Maintain a positive and professional attitude throughout the interview.

- Wear business attire to convey professionalism and respect

- Be punctual to show that you value the interviewer’s time and consideration

Next Step:

Now that you’re armed with the knowledge of Coping Machine Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coping Machine Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini