Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Coppersmith interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Coppersmith so you can tailor your answers to impress potential employers.

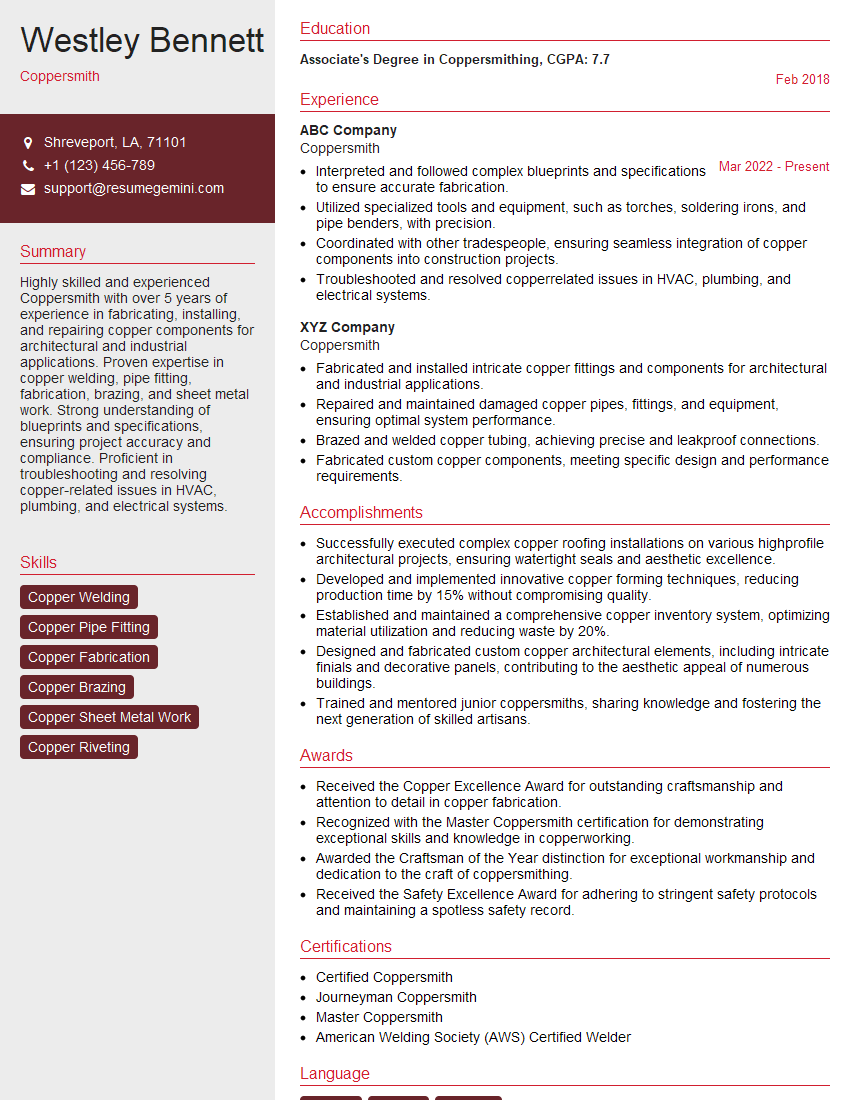

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coppersmith

1. How do you determine the thickness of copper that is required for a given application?

To determine the thickness of copper required for a given application, I consider several factors:

- Current carrying capacity: The thickness of the copper should be sufficient to carry the expected current without overheating.

- Voltage drop: The thicker the copper, the lower the voltage drop over a given distance.

- Mechanical strength: The copper thickness should provide adequate mechanical strength to withstand the intended application.

- Environmental factors: The copper thickness should take into account factors such as corrosion, temperature, and humidity.

- Cost: Thicker copper is more expensive, so the cost must be balanced against the other factors.

2. What are the different types of copper alloys, and how are they used in electrical applications?

Types of Copper Alloys

- Copper-zinc alloys (brass): Used for electrical contacts, springs, and musical instruments.

- Copper-tin alloys (bronze): Used for bearings, gears, and statues.

- Copper-aluminum alloys: Used for electrical conductors, heat exchangers, and marine applications.

- Copper-nickel alloys (cupronickel): Used for marine applications, coinage, and electrical components.

- Copper-beryllium alloys: Used for springs, electrical contacts, and non-sparking tools.

Uses in Electrical Applications

- Copper-aluminum alloys: High conductivity and low weight, making them suitable for overhead power lines.

- Copper-beryllium alloys: Excellent electrical conductivity and springiness, making them ideal for electrical contacts.

- Copper-nickel alloys: Corrosion-resistant and have good electrical conductivity, making them suitable for marine applications and electrical components.

3. How do you calculate the resistance of a copper wire?

The resistance (R) of a copper wire can be calculated using the formula: R = (ρ * L) / A where:

- ρ is the resistivity of copper (1.68 x 10^-8 ohm-meters)

- L is the length of the wire (meters)

- A is the cross-sectional area of the wire (square meters)

4. What are the advantages and disadvantages of using copper for electrical applications?

Advantages

- High electrical conductivity

- Good thermal conductivity

- Ductile and malleable

- Corrosion-resistant

- Recyclable

Disadvantages

- Expensive compared to some other metals

- Can be susceptible to oxidation and tarnishing

- Heavy

5. How do you ensure the quality of copper products?

Ensuring the quality of copper products involves several steps:

- Raw material inspection: Inspecting the raw copper for impurities and defects.

- Manufacturing process control: Monitoring the manufacturing process to ensure it meets specifications.

- Testing and inspection: Performing electrical, mechanical, and chemical tests to verify the quality of the finished products.

- Traceability: Maintaining records to track the origin and history of each copper product.

- Certification: Obtaining certifications from recognized organizations to demonstrate compliance with industry standards.

6. What are the emerging trends in copper manufacturing and applications?

Copper manufacturing and applications are evolving with advancements in technology and changing market needs:

- Nano-copper: Research into using nano-sized copper particles to enhance electrical conductivity and thermal properties.

- Additive manufacturing: Using 3D printing techniques to create complex copper components with improved performance.

- Copper in renewable energy: Increasing use of copper in solar panels, electric vehicles, and energy storage systems.

- Sustainable copper production: Development of environmentally friendly mining and refining techniques.

- Smart copper products: Integration of copper with sensors and electronics to create intelligent devices.

7. How do you stay updated with the latest developments in copper technology?

To stay updated with the latest developments in copper technology, I engage in the following activities:

- Attending industry conferences and webinars: Participating in events where experts share new research and advancements.

- Reading technical publications: Subscribing to journals and magazines that cover copper-related topics.

- Networking with peers: Connecting with professionals in the field through LinkedIn and industry organizations.

- Researching online: Exploring reputable websites and databases for up-to-date information.

- Collaboration: Partnering with universities and research institutions to gain access to cutting-edge knowledge.

8. What is your understanding of the role of copper in the development of electric vehicles?

Copper plays a crucial role in the development of electric vehicles due to its excellent electrical conductivity:

- Battery packs: Copper is used in the interconnections within battery packs, enabling efficient power transfer.

- Electric motors: Copper windings in electric motors generate the magnetic field necessary for operation.

- Wiring harnesses: Copper wires connect various components within the vehicle, facilitating power distribution and signal transmission.

- Charging infrastructure: Copper is used in charging stations and cables to deliver electricity to the vehicle’s battery.

9. How do you approach the design of a copper busbar system?

Designing a copper busbar system involves the following steps:

- Load analysis: Determining the current carrying capacity and voltage requirements of the system.

- Material selection: Choosing the appropriate grade of copper based on conductivity, strength, and environmental factors.

- Busbar sizing: Calculating the cross-sectional area of the busbars to meet the current carrying capacity and minimize voltage drop.

- Layout and configuration: Determining the optimal arrangement of busbars and supports to ensure electrical efficiency and mechanical stability.

- Connections: Designing reliable connections between busbars, ensuring proper electrical contact and current transfer.

10. What are the challenges and opportunities in the copper industry?

Challenges

- Fluctuating copper prices: Market volatility can impact the profitability of copper production and consumption.

- Environmental concerns: Mining and processing copper can have environmental impacts, requiring responsible practices.

- competition from alternative materials: Other conductive materials, such as aluminum, can pose competition to copper in certain applications.

Opportunities

- Growing demand for copper: The increasing use of copper in electrical applications, renewable energy, and electric vehicles creates growth opportunities.

- Technological advancements: Research and development lead to new alloys and manufacturing techniques, enhancing copper’s performance.

- Sustainability initiatives: Exploring eco-friendly mining and recycling practices can improve the industry’s environmental footprint.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coppersmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coppersmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coppersmiths are responsible for fabricating, installing, and repairing copper and copper alloy products. They work with a variety of tools and equipment to create custom-made pieces that are both functional and aesthetically pleasing.

1. Fabrication

Coppersmiths are skilled craftsmen who can create custom-made copper and copper alloy products from scratch. They use a variety of techniques to fabricate these products, including cutting, soldering, brazing, and welding. Coppersmiths must be able to read blueprints and follow instructions to create products that meet the specifications of their clients.

- Cut and shape copper and copper alloy sheets, tubes, and rods

- Solder, braze, and weld copper and copper alloys

- Assemble and install copper and copper alloy products

2. Installation

Coppersmiths are also responsible for installing copper and copper alloy products. They must be able to work safely and efficiently to ensure that the products are installed correctly. Coppersmiths must also be able to troubleshoot problems and make repairs as needed.

- Install copper and copper alloy roofing, gutters, and downspouts

- Install copper and copper alloy flashing and trim

- Install copper and copper alloy plumbing and heating systems

3. Repair

Coppersmiths are also responsible for repairing copper and copper alloy products. They must be able to identify the source of the problem and make the necessary repairs. Coppersmiths must also be able to work safely and efficiently to ensure that the repairs are made correctly.

- Repair copper and copper alloy roofing, gutters, and downspouts

- Repair copper and copper alloy flashing and trim

- Repair copper and copper alloy plumbing and heating systems

4. Maintenance

Coppersmiths may also be responsible for maintaining copper and copper alloy products. They must be able to inspect these products for signs of wear and tear and make any necessary repairs. Coppersmiths must also be able to provide advice on how to care for and maintain copper and copper alloy products.

- Inspect copper and copper alloy products for signs of wear and tear

- Clean and polish copper and copper alloy products

- Apply protective coatings to copper and copper alloy products

Interview Tips

Preparing for a job interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a coppersmith position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in news articles, and on social media. You can also learn more about the position by reading the job description and talking to people who work in the industry.

- Visit the company’s website

- Read news articles about the company

- Follow the company on social media

- Talk to people who work in the industry

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and clearly. You can also prepare for other questions by thinking about your experiences and skills.

- “Tell me about yourself”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the workplace. You should also avoid wearing excessive jewelry or makeup.

- Wear clean, pressed clothes

- Dress appropriately for the workplace

- Avoid wearing excessive jewelry or makeup

4. Be on time

Punctuality is important for any job interview, but it’s especially important for a coppersmith position. This is because coppersmiths are often required to work on deadlines, and they need to be able to manage their time effectively. If you’re running late for your interview, be sure to call the interviewer and let them know.

- Plan your route ahead of time

- Allow extra time for unexpected delays

- Call the interviewer if you’re running late

5. Be prepared to talk about your experience and skills

During your interview, the interviewer will likely ask you questions about your experience and skills. Be prepared to talk about your previous work experience, your skills, and your education. You should also be able to explain why you’re interested in the position and why you’re the best candidate for the job.

- Talk about your previous work experience

- Discuss your skills and abilities

- Explain why you’re interested in the position

- Explain why you’re the best candidate for the job

6. Ask questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is your chance to learn more about the position and the company. It’s also a good way to show the interviewer that you’re interested in the job and that you’re taking the interview seriously.

- Ask about the company’s culture

- Ask about the specific requirements of the job

- Ask about the company’s future plans

Next Step:

Now that you’re armed with the knowledge of Coppersmith interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coppersmith positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini