Feeling lost in a sea of interview questions? Landed that dream interview for Copping Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Copping Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

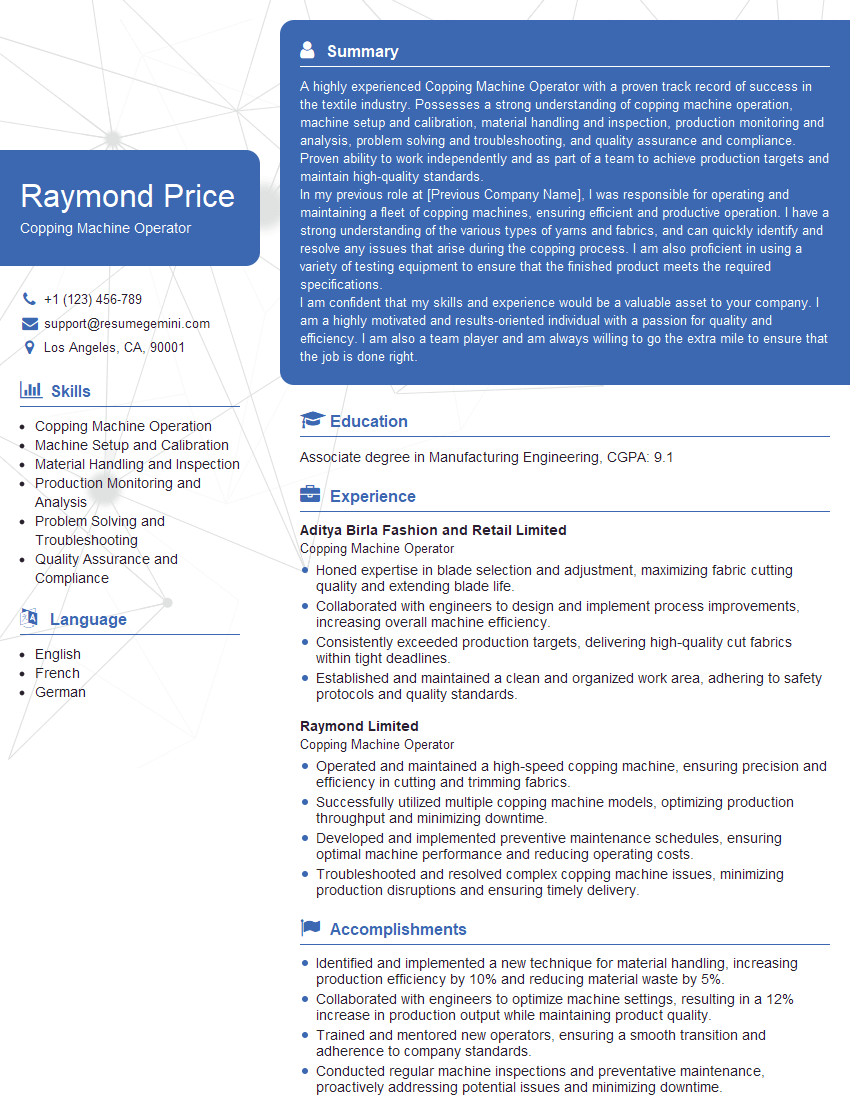

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Copping Machine Operator

1. What is a copping machine, and how does it work?

A copping machine is a sophisticated textile machinery constructed to wind yarn onto conical packages, precisely known as cops. The machine consists of a series of spindles mounted on a rotating frame. Each spindle holds an empty cop tube, and the yarn is fed through a guide and onto the tube as the frame rotates. The winding process is controlled by a computer program, which ensures that the yarn is evenly distributed across the cop and that the desired package density is achieved.

2. What are the different types of copping machines?

Manual Copping Machines

- Manually operated

- Simple design

- Low production capacity

Semi-Automatic Copping Machines

- Partially automated

- Operator loads empty tubes and starts the machine

- Machine stops automatically when cops are full

Fully-Automatic Copping Machines

- Fully automated

- Operator only needs to load yarn and remove full cops

- High production capacity

3. What are the key features of a copping machine?

- Number of spindles

- Spindle speed

- Traverse rate

- Yarn tension control

- Cop weight

4. What are the different types of yarn that can be used on a copping machine?

- Cotton

- Polyester

- Nylon

- Acrylic

- Wool

5. What are the common problems that can occur with copping machines?

- Yarn breakage

- Uneven winding

- Loose cops

- Mechanical breakdowns

6. How do you troubleshoot a copping machine?

Troubleshooting a copping machine involves a systematic approach to identify and resolve any issues that may arise. The following steps provide a general guideline:

- Identify the problem

- Check the yarn tension

- Inspect the machine for any mechanical issues

- Clean the machine

- Calibrate the machine

7. What is the maintenance schedule for a copping machine?

The maintenance schedule for a copping machine typically includes the following tasks:

- Daily cleaning

- Weekly inspection

- Monthly lubrication

- Yearly overhaul

8. What are the safety precautions that should be taken when operating a copping machine?

- Wear appropriate safety gear

- Keep hands away from moving parts

- Be aware of the machine’s surroundings

- Follow the manufacturer’s instructions

9. How do you calculate the production rate of a copping machine?

The production rate of a copping machine can be calculated using the following formula:

- Production rate = (Number of spindles) x (Spindle speed) x (Traverse rate) x (Yarn linear density)

10. What are the latest trends in copping machine technology?

- Increased automation

- Improved yarn quality

- Reduced production costs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Copping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Copping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Copping Machine Operators perform various duties related to the operation and maintenance of copping machines in textile manufacturing facilities.

1. Machine Operation and Maintenance

Operate copping machines to wind yarn onto cops and cones

- Set up and adjust machines for different yarn types and specifications

- Monitor machine operations, adjust settings, and make necessary repairs

2. Quality Control

Inspect yarn for defects and ensure it meets quality standards.

- Identify and correct yarn breaks and other production issues

- Maintain records of production and quality control parameters

3. Material Handling

Load and unload yarn materials onto and off the copping machines.

- Move yarn from one production area to another

- Handle and store materials safely and efficiently

4. Safety and Compliance

Follow safety protocols and maintain a clean and organized work environment.

- Use personal protective equipment as required

- Comply with industry standards and regulations

Interview Tips

Preparing for an interview can help you present yourself confidently and highlight your qualifications for the Copping Machine Operator position. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website and industry news to demonstrate your interest and knowledge of the field.

- Learn about the company’s products, services, and market position.

- Research industry trends and advancements to show your understanding of the textile manufacturing sector.

2. Practice Your Technical Skills

Review the key job responsibilities and practice answering questions related to your technical skills in operating and maintaining copping machines.

- Describe your experience in setting up and adjusting copping machines for various yarn types.

- Explain how you troubleshoot and resolve common production issues.

3. Emphasize Quality Control

Highlight your attention to detail and commitment to maintaining high-quality standards.

- Provide examples of how you have identified and corrected yarn defects during production.

- Explain your knowledge of quality control procedures and industry standards.

4. Showcase Safety and Compliance

Demonstrate your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Discuss your experience in using personal protective equipment and following established safety guidelines.

- Explain how you prioritize safety and compliance in your work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Copping Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.