Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Copy Lathe Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Copy Lathe Tender so you can tailor your answers to impress potential employers.

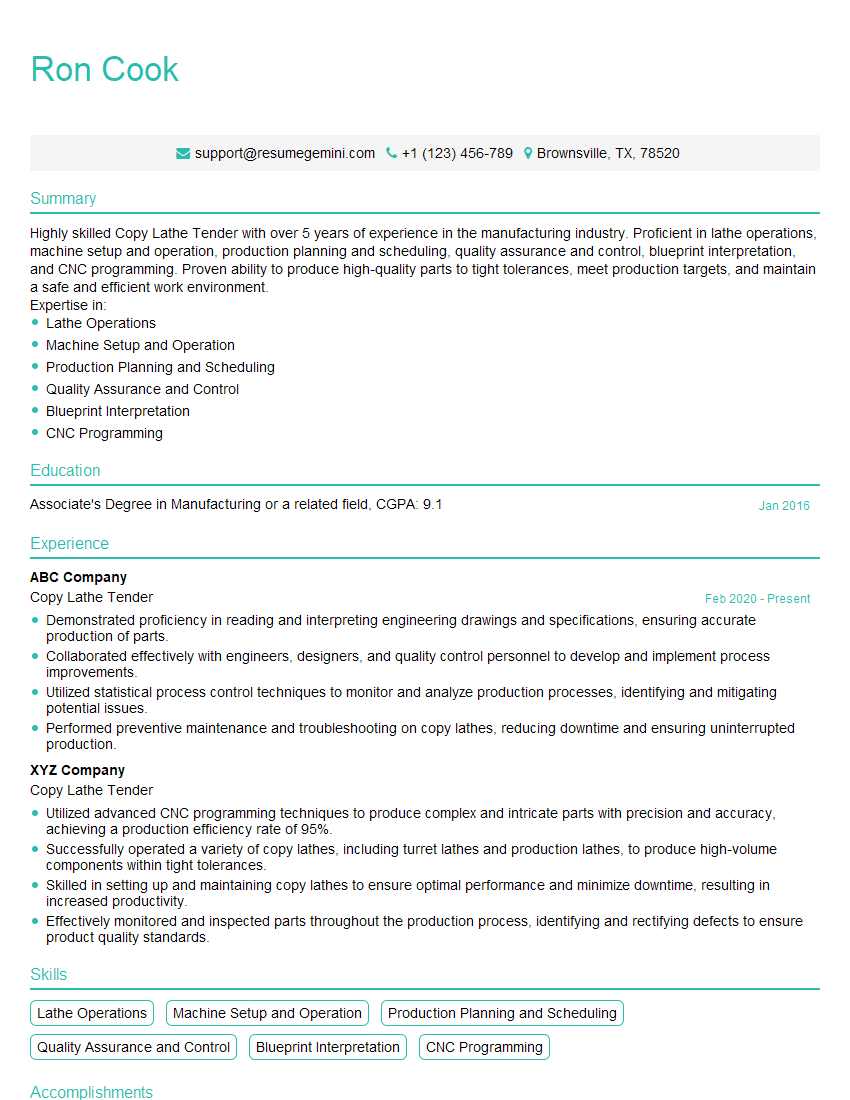

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Copy Lathe Tender

1. Describe the process of setting up a copy lathe for a specific job order.

To set up a copy lathe for a specific job order, I would follow these steps:

- Review the job order and drawings to understand the required part dimensions and tolerances.

- Select the appropriate tooling and accessories for the job, including the correct lathe tool, chuck, and steady rest.

- Install the tooling onto the lathe and align it precisely using dial indicators or other precision measuring instruments.

- Mount the workpiece securely onto the lathe chuck or between centers.

- Set the spindle speed and feed rate according to the material being machined and the desired surface finish.

- Program the lathe controller with the required toolpaths and machining parameters.

- Calibrate the tool probe to match the expected dimensions.

2. Explain the different methods used to hold workpieces on a copy lathe.

There are several methods used to hold workpieces on a copy lathe:

Chuck

- A chuck is a device that holds the workpiece securely while it is being machined.

- Chucks come in various types, including three-jaw chucks, four-jaw chucks, and collet chucks.

- The type of chuck used will depend on the size, shape, and material of the workpiece.

Centers

- Centers are used to support the workpiece between the headstock and tailstock of the lathe.

- Centers are typically used for long and slender workpieces.

Fixtures

- Fixtures are custom-designed devices that hold the workpiece securely and accurately.

- Fixtures are often used for complex workpieces or for workpieces that require multiple machining operations.

3. Describe the role of the template in a copy lathe operation.

The template in a copy lathe operation plays a crucial role in guiding the cutting tool to produce the desired shape on the workpiece.

- The template is a physical representation of the desired part profile.

- The template is mounted on the lathe’s template holder and is in constant contact with a tracer or follower system.

- As the template moves, the tracer or follower system translates its movements into corresponding movements of the cutting tool.

- This ensures that the cutting tool follows the contours of the template, resulting in a workpiece with the desired shape and dimensions.

4. Explain the importance of coolant in copy lathe operations.

Coolant is crucial in copy lathe operations for several reasons:

- It helps to reduce friction between the cutting tool and the workpiece, preventing excessive heat buildup and tool wear.

- Coolant flushes away chips and debris from the cutting zone, ensuring a clean and precise cutting process.

- It prevents the workpiece from overheating, which can cause distortion or damage.

- Coolant also acts as a lubricant, reducing the cutting forces required and improving the surface finish of the workpiece.

5. Describe the different types of materials that can be machined on a copy lathe.

A copy lathe can be used to machine a wide range of materials, including:

- Metals: such as steel, aluminum, brass, and copper.

- Plastics: such as acrylic, polycarbonate, and nylon.

- Wood: such as hardwood and softwood.

- Composites: such as fiberglass and carbon fiber.

- The choice of material will depend on the specific application and the desired properties of the finished part.

6. Explain the advantages and disadvantages of using a copy lathe.

Advantages:

- Copy lathes are highly efficient for producing complex shapes with repetitive profiles.

- They can achieve high levels of accuracy and repeatability.

- Copy lathes reduce the need for skilled labor, as the template guides the cutting tool.

Disadvantages:

- Copy lathes are less versatile than conventional lathes and can only produce parts that conform to the template.

- They can be more expensive than conventional lathes.

- Copy lathes require careful setup and maintenance to ensure accuracy and precision.

7. Describe the safety precautions that should be taken when operating a copy lathe.

Operating a copy lathe requires adherence to several safety precautions to ensure the safety of the operator and others around:

- Always wear appropriate safety gear, including safety glasses, earplugs, and protective clothing.

- Ensure the lathe is properly grounded to prevent electrical hazards.

- Inspect the lathe and all tooling before each use to ensure they are in good working condition.

- Securely mount the workpiece and use the appropriate chuck or fixture.

- Never operate the lathe with loose clothing or jewelry that could get caught in moving parts.

- Keep the work area clean and free of debris to prevent tripping hazards.

- Never leave the lathe running unattended.

- Follow proper lockout/tagout procedures when performing maintenance or repairs.

8. Explain how to troubleshoot common problems that can occur during a copy lathe operation.

During copy lathe operations, various common problems can occur, and troubleshooting them promptly is essential:

- Chattering or vibration: Check for tool wear, improper workpiece mounting, or excessive feed rates.

- Poor surface finish: Inspect the cutting tool for sharpness, adjust the feed rate or spindle speed, and verify the template condition.

- Tool breakage: Ensure the tool is securely held, the workpiece is properly mounted, and the cutting parameters are appropriate for the material.

- Workpiece slipping: Tighten the chuck or fixture securely and use the appropriate hold-down devices.

- Coolant issues: Check the coolant supply, ensure the coolant is flowing properly, and clean any blockages.

9. Describe the maintenance procedures for a copy lathe.

Regular maintenance is crucial to keep a copy lathe operating smoothly and accurately:

- Daily maintenance: includes cleaning the lathe, lubricating moving parts, and checking the coolant system.

- Weekly maintenance: involves inspecting the spindle bearings, belts, and electrical connections.

- Monthly maintenance: includes calibrating the lathe’s accuracy and checking the template for wear.

- Annual maintenance: requires a thorough inspection of the lathe, including disassembling and cleaning major components.

10. Explain how you keep up-to-date with the latest advancements in copy lathe technology.

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Network with other copy lathe professionals.

- Participate in online forums and discussion groups.

- Research and explore new technologies and their applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Copy Lathe Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Copy Lathe Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Copy Lathe Tender has a crucial role in a manufacturing setting, deftly operating lathe machines to produce precise and intricate metal components. Their key job responsibilities encompass:

1. Setup and Operation

• Configuring lathe machines to specifications, adjusting speeds, feeds, and cutting tools

• Loading and securing raw materials (e.g., metal bars, tubes) into the lathe

• Monitoring the machining process, ensuring smooth operation and adherence to quality standards

2. Quality Control

• Inspecting machined parts for accuracy, dimensions, and surface finish

• Using measuring instruments (e.g., calipers, micrometers) to verify compliance with specifications

• Identifying and rectifying any deviations from the required tolerances

3. Maintenance and Troubleshooting

• Lubricating and maintaining lathe machines to ensure optimal performance

• Troubleshooting and resolving minor technical issues or malfunctions

• Reporting major problems to supervisors or maintenance personnel for prompt resolution

4. Production Efficiency

• Monitoring production rates to meet targets and maintain efficiency

• Optimizing machine parameters to minimize cycle times and maximize output

• Identifying and implementing process improvements to enhance productivity

Interview Tips

To ace the interview for a Copy Lathe Tender position, meticulous preparation is key. Here are some valuable tips:

1. Research the Company and Role

• Gather information about the company’s industry, products, and culture

• Study the job description thoroughly, highlighting your relevant skills and experience

2. Highlight Your Technical Proficiency

• Demonstrate your expertise in lathe machine operation and maintenance

• Discuss your experience in using measuring instruments and performing quality inspections

• Provide examples of how you have optimized production efficiency or resolved technical challenges

3. Emphasize Your Attention to Detail

• Stress your meticulous nature and commitment to producing high-quality work

• Share instances where your keen eye for detail resulted in the identification and correction of errors

• Explain how you maintain a clean and organized work area to ensure safety and efficiency

4. Prepare for Common Interview Questions

• Practice answering questions about your experience, skills, and motivations

• Examples of common questions include:

- “Tell me about your experience operating copy lathe machines.”

- “How do you ensure the accuracy and quality of machined parts?”

- “What steps do you take to troubleshoot and resolve technical issues?”

- “How have you contributed to improving production efficiency in previous roles?”

5. Showcase Your Enthusiasm and Work Ethic

• Express your passion for precision machining and your dedication to delivering exceptional results

• Highlight your willingness to work independently and as part of a team

• Convey your desire to learn and grow within the organization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Copy Lathe Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.