Are you gearing up for an interview for a Cord Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cord Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

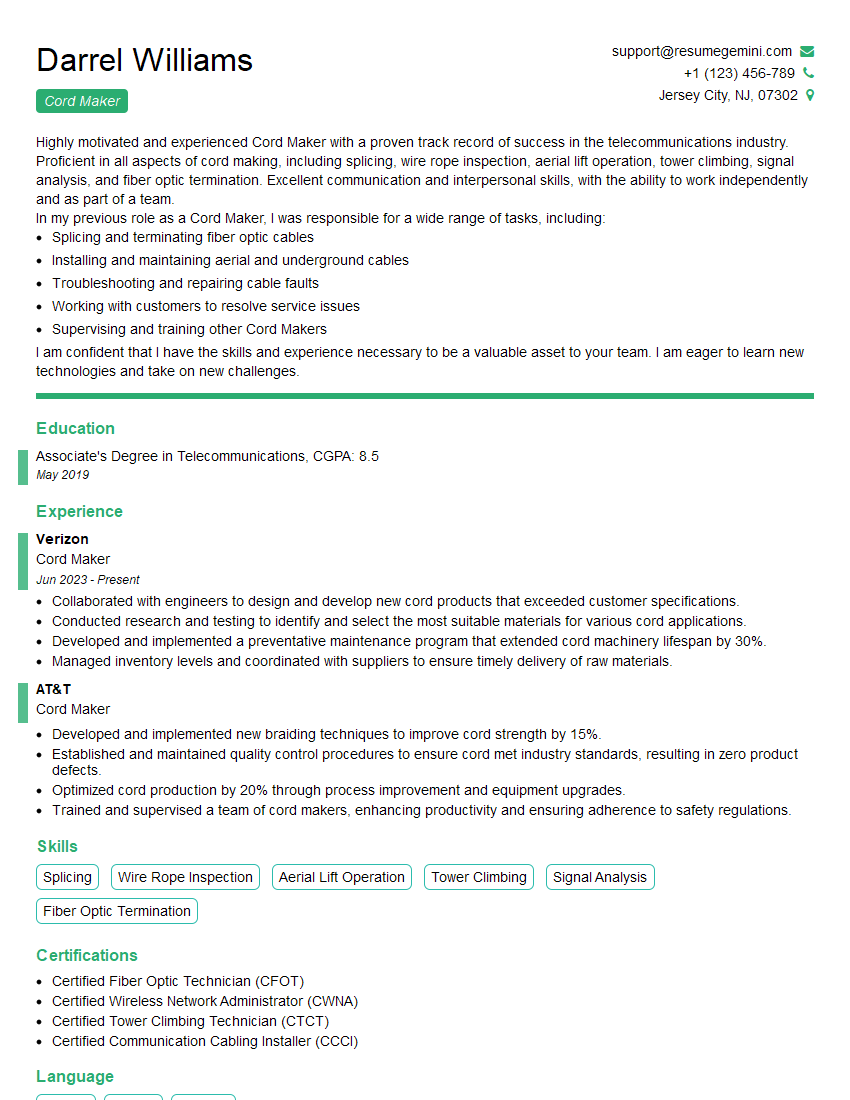

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cord Maker

1. Explain the different types of cords you have produced and the materials used in their construction?

- Braided cords: These cords are made by interlacing three or more strands of yarn or thread. They are strong and durable, and can be used for a variety of purposes, such as shoelaces, rope, and electrical wire.

- Twisted cords: These cords are made by twisting two or more strands of yarn or thread together. They are less strong than braided cords, but they are more flexible and easier to work with. They can be used for a variety of purposes, such as embroidery floss, sewing thread, and yarn for knitting and crocheting.

- Extruded cords: These cords are made by forcing a molten plastic or rubber material through a die. They are strong and durable, and can be made in a variety of shapes and sizes. They can be used for a variety of purposes, such as power cords, phone cords, and computer cables.

2. Describe the steps involved in the cord making process?

Raw material preparation

- The first step in the cord making process is to prepare the raw materials. This may involve spinning yarn from fibers, twisting fibers together, or extruding plastic or rubber.

- The prepared raw materials are then wound onto bobbins or spools.

Cord formation

- The next step is to form the cords. This can be done by braiding, twisting, or extruding the raw materials.

- The cords are then wound onto reels or spools.

Finishing

- The final step in the cord making process is to finish the cords. This may involve dyeing, coating, or heat treating the cords.

- The finished cords are then packaged and shipped to customers.

3. What are the key factors that affect the quality of a cord?

- The quality of the raw materials.

- The cord making process.

- The finishing process.

- The storage conditions.

4. What are the different types of cord making machines?

- Braiding machines.

- Twisting machines.

- Extruding machines.

5. What are the safety precautions that must be taken when operating a cord making machine?

- Wear appropriate safety clothing and equipment, such as safety glasses, gloves, and a hard hat.

- Keep the work area clean and free of debris.

- Be aware of the moving parts of the machine and keep hands and other body parts away from them.

- Do not operate the machine if it is damaged or not functioning properly.

- Follow all manufacturer’s instructions for safe operation.

6. How do you troubleshoot a cord making machine?

- First, identify the problem.

- Then, consult the manufacturer’s instructions for troubleshooting.

- If the problem cannot be resolved, contact a qualified technician.

7. What are the different types of cord testing?

- Tensile testing: This test measures the strength of a cord by pulling it until it breaks.

- Elongation testing: This test measures how much a cord stretches before it breaks.

- Abrasion testing: This test measures how resistant a cord is to wear and tear.

- Heat testing: This test measures how well a cord withstands heat.

- Electrical testing: This test measures the electrical properties of a cord.

8. What are the different types of cord packaging?

- Spools.

- Reels.

- Coils.

- Hanks.

- Skeins.

9. What are the storage conditions for cords?

- Cords should be stored in a cool, dry place.

- Cords should not be exposed to direct sunlight or heat.

- Cords should not be stored in a damp or humid environment.

- Cords should be stored away from sharp objects.

10. Besides the technical skills required for cord making, do you possess any additional skills that would make you a valuable asset to our company?

- I am a highly motivated and results-oriented individual.

- I am a team player and I am able to work independently.

- I am a quick learner and I am always willing to take on new challenges.

- I am a good communicator and I am able to build strong relationships with customers and colleagues.

- I am a detail-oriented individual and I am able to produce high-quality work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cord Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cord Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cord makers are responsible for operating and maintaining cord making machinery, which produces cords, ropes, and twines used in a variety of industries, such as construction, agriculture, and manufacturing.1. Machine Operation and Maintenance

- Operate and monitor cord making machines, ensuring proper functioning and product quality.

- Perform routine maintenance and repairs on machinery, including cleaning, lubrication, and adjustments

- Diagnose and troubleshoot machine malfunctions, identifying and addressing issues promptly.

2. Production Planning and Scheduling

- Plan and schedule production runs based on customer orders and production targets.

- Estimate production times, material requirements, and crew assignments.

- Monitor production progress, making adjustments as needed to maintain efficiency and quality.

3. Raw Material Management

- Inspect and prepare raw materials, ensuring they meet specifications and quality standards.

- Maintain inventory levels of raw materials, tracking usage and ordering new supplies as needed.

- Store and handle raw materials safely and securely, adhering to industry regulations and best practices.

4. Quality Control and Testing

- Inspect finished cords, ropes, and twines for defects and non-conformances.

- Test and analyze products to ensure they meet physical and performance specifications.

- Maintain quality control records and documentation, recording test results and any deviations from standards.

5. Safety and Compliance

- Follow established safety protocols and wear appropriate personal protective equipment (PPE).

- Adhere to industry regulations and standards related to cord making and raw material handling.

- Maintain a clean and organized work environment, minimizing potential hazards and promoting safety.

Interview Tips

1. Research the Company and Industry

- Visit the company’s website to learn about their history, products, and culture.

- Research the cord making industry, including trends, advancements, and major players.

- Look for news articles and industry publications to gain insights into the current market landscape.

2. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?”

- Practice answering technical questions related to cord making machinery, production processes, and quality control.

- Be ready to share examples of your experience and skills that demonstrate your ability to excel in the role.

3. Highlight Your Skills and Experience

- Emphasize your proficiency in cord making machinery operation and maintenance.

- Demonstrate your skills in production planning, scheduling, and raw material management.

- Provide examples of your experience in implementing quality control measures and ensuring compliance.

4. Be Enthusiastic and Professional

- Show genuine interest in the role and the company, conveying your eagerness to contribute.

- Dress professionally, arrive on time, and maintain a positive and respectful demeanor throughout the interview.

- Ask thoughtful questions to demonstrate your engagement and understanding of the position and organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cord Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!