Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Core Cutter and Reamer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Core Cutter and Reamer so you can tailor your answers to impress potential employers.

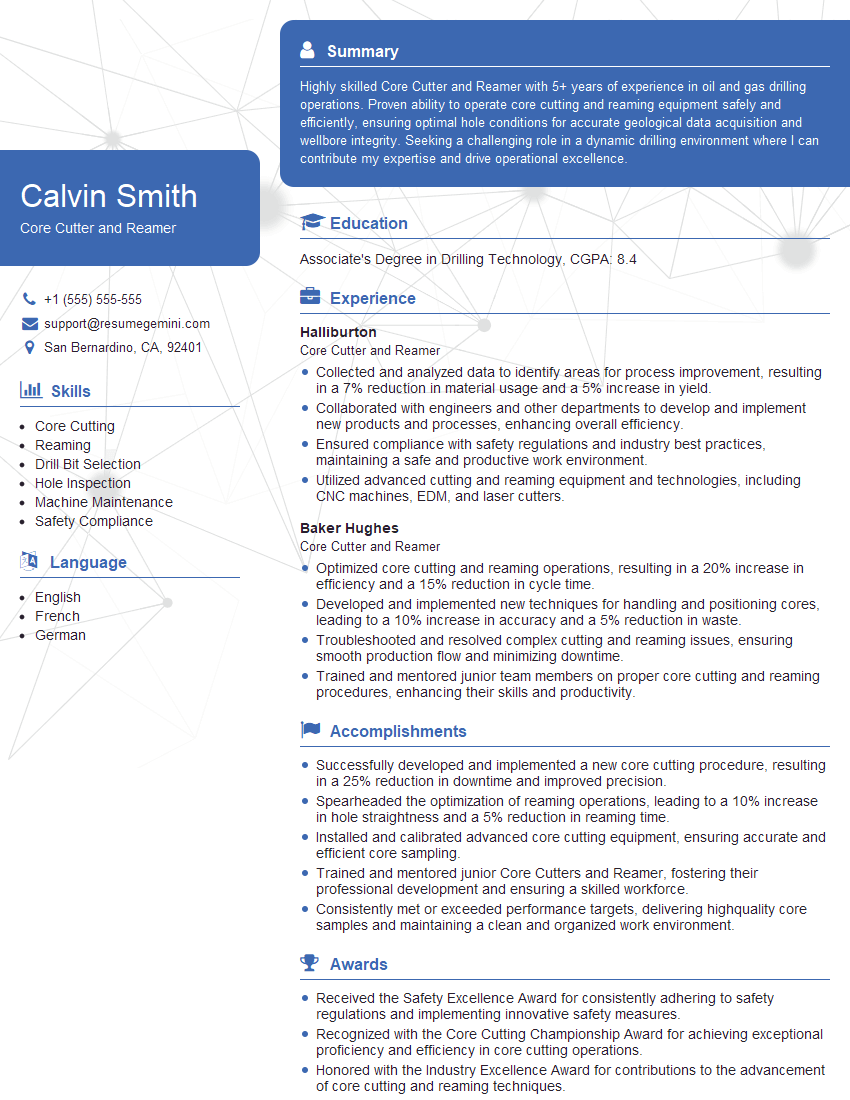

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Cutter and Reamer

1. What are the primary responsibilities of a Core Cutter and Reamer?

The primary responsibilities of a Core Cutter and Reamer include:

- Operating core cutters and reamers to cut and finish holes and cavities in various materials.

- Setting up and operating CNC or manual machines to create precise cuts and reamed surfaces.

- Inspecting and measuring finished products to ensure they meet specifications.

- Maintaining and repairing equipment, including core cutters and reamers.

- Following safety procedures and using proper protective gear.

2. Describe the different types of core cutters and reamers and their uses.

Fluted Core Cutters

- Used for cutting clean, round holes in various materials.

- Available in various sizes and flute counts for different hole diameters and applications.

Annular Cutters

- Designed for cutting large-diameter holes quickly and efficiently.

- Produce a thin, cylindrical core that is removed through the center of the cutter.

Reamers

- Used for enlarging or finishing holes to precise dimensions.

- Available in various types, including hand reamers, machine reamers, and adjustable reamers.

3. What factors should be considered when selecting the correct core cutter or reamer for a specific application?

When selecting the correct core cutter or reamer, the following factors should be considered:

- Material being cut

- Hole diameter and depth

- Tolerance requirements

- Machine capabilities

- Cost and availability

4. What are the proper techniques for using core cutters and reamers safely and effectively?

To use core cutters and reamers safely and effectively, it is important to:

- Wear appropriate safety gear, including eye protection, gloves, and hearing protection.

- Secure the workpiece properly to prevent movement during cutting.

- Use sharp and properly sized tools for the job.

- Maintain a steady cutting speed and feed rate.

- Inspect tools regularly for wear or damage.

5. How do you ensure that the finished product meets the specified tolerances and surface finish requirements?

To ensure that the finished product meets the specified tolerances and surface finish requirements, I follow these steps:

- Inspect the workpiece before cutting to verify that it is the correct size and shape.

- Use sharp and properly sized tools for the job.

- Maintain a steady cutting speed and feed rate.

- Measure the finished product using precision measuring tools.

- Make adjustments to the cutting process as needed to achieve the desired results.

6. What are some of the common problems that can occur when using core cutters and reamers, and how do you troubleshoot them?

Some common problems that can occur when using core cutters and reamers include:

- Tool chatter: This can be caused by dull tools, excessive feed rates, or improper workpiece clamping.

- Hole size deviation: This can be caused by using worn or incorrectly sized tools, or by excessive cutting forces.

- Surface finish issues: This can be caused by dull tools, excessive feed rates, or insufficient lubrication.

- Tool breakage: This can be caused by excessive cutting forces, dull tools, or using the wrong tool for the job.

To troubleshoot these problems, I would:

- Inspect the tool for wear or damage.

- Adjust the feed rate or cutting speed.

- Check the workpiece clamping to ensure it is secure.

- Use a different tool or lubricant.

7. What is your experience with using different types of CNC machines for core cutting and reaming operations?

I have extensive experience using different types of CNC machines for core cutting and reaming operations, including:

- Vertical machining centers (VMCs)

- Horizontal machining centers (HMCs)

- Computer numerical controlled (CNC) lathes

- Multi-axis machining centers

I am proficient in programming and operating these machines to produce high-quality parts with precision and accuracy.

8. Can you describe the different types of materials that you have experience cutting and reaming?

I have experience cutting and reaming a wide variety of materials, including:

- Metals (steel, aluminum, stainless steel, titanium)

- Plastics (acrylic, polycarbonate, PVC)

- Composites (carbon fiber, fiberglass)

- Wood

- Glass

I am familiar with the different properties and machining characteristics of these materials, and I can select the appropriate cutting tools and parameters to achieve the desired results.

9. What quality control procedures do you follow to ensure the accuracy and precision of your work?

I follow a comprehensive set of quality control procedures to ensure the accuracy and precision of my work, including:

- Inspecting raw materials to verify that they meet specifications.

- Using calibrated measuring tools and equipment.

- Following established cutting and reaming parameters.

- Inspecting finished parts to ensure that they meet the required tolerances and surface finish.

- Documenting all inspection and measurement data.

10. Can you provide examples of projects where you have successfully used core cutting and reaming techniques to create complex or high-precision parts?

Yes, I have worked on several projects where I have successfully used core cutting and reaming techniques to create complex or high-precision parts, including:

- A medical device that required precise holes to be cut and reamed for surgical implants.

- An aerospace component that required complex contours to be cut and reamed with high accuracy.

- A mold for a plastic part that required intricate details to be cut and reamed.

In each of these projects, I was able to successfully meet the customer’s requirements for precision, accuracy, and surface finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Cutter and Reamer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Cutter and Reamer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Core Cutter and Reamer, you will be responsible for performing a range of tasks related to core cutting and reaming operations. Some of your key responsibilities will include:

1. Core Cutting

Selecting and setting up core drilling equipment

- Establishing and maintaining proper drilling parameters

- Collecting and preserving core samples

2. Reaming

Preparing boreholes for reaming operations

- Enlarging boreholes to the desired size and shape

- Ensuring that reamed boreholes meet specified tolerances

3. Equipment Maintenance

Performing routine maintenance on core drilling and reaming equipment

- Troubleshooting and repairing equipment as needed

- Maintaining a clean and organized work area

4. Health and Safety

Complying with all applicable health and safety regulations

- Wearing appropriate personal protective equipment

- Following established safety procedures

Interview Tips

Preparing for an interview for a Core Cutter and Reamer position requires careful planning and execution. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take some time to learn about the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and will also give you a better idea of what the job entails.

- Visit the company’s website

- Read industry news and articles

- Connect with employees on LinkedIn

2. Prepare Your Responses to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to prepare your responses to these questions in advance so that you can deliver them confidently and clearly.

- Practice your answers out loud

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Tailor your answers to the specific job you are applying for

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Avoid wearing casual clothing, such as jeans or t-shirts

- Choose clothes that are comfortable and allow you to move around easily

- Make sure your clothes are clean and wrinkle-free

4. Be Punctual

Punctuality shows that you are respectful of the interviewer’s time. Arrive for your interview on time, if not a few minutes early.

- Plan your route in advance and allow for extra time in case of traffic

- If you are running late, call or email the interviewer to let them know

- Do not arrive for your interview more than 15 minutes early

Next Step:

Now that you’re armed with the knowledge of Core Cutter and Reamer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Core Cutter and Reamer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini