Are you gearing up for an interview for a Core Drier position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Core Drier and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

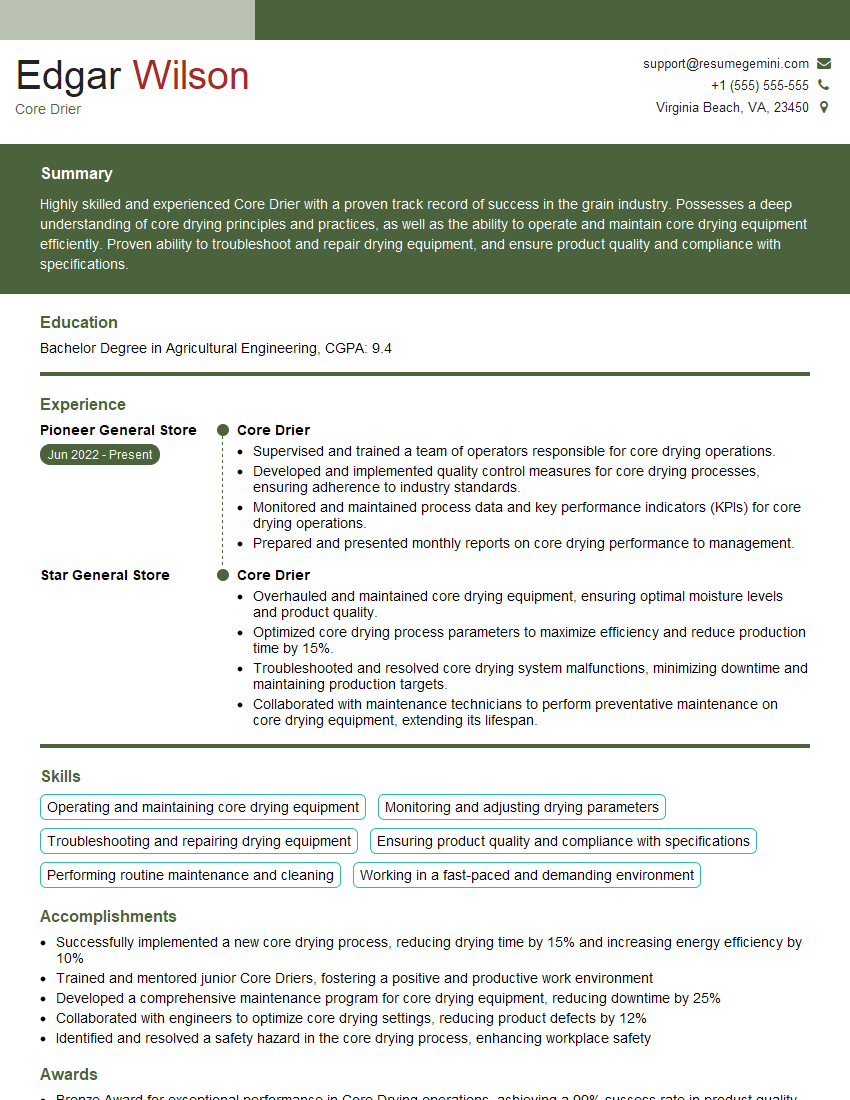

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Drier

1. What is the principle behind the operation of a core drier?

A core drier is a device that removes moisture from the core of a product, such as food or paper. The principle behind the operation of a core drier is to circulate hot air or other heated medium around the core of the product, causing the moisture to evaporate and be removed from the product.

2. What are the different types of core driers?

There are two main types of core driers: batch core driers and continuous core driers.

Batch core driers

- Batch core driers are used to dry small batches of product at a time.

- The product is placed in a chamber and hot air is circulated around the product.

- Batch core driers are typically used for products that are delicate or that require a long drying time.

Continuous core driers

- Continuous core driers are used to dry large volumes of product at a time.

- The product is fed into the drier on a conveyor belt and hot air is circulated around the product as it moves through the drier.

- Continuous core driers are typically used for products that are not delicate and that have a short drying time.

3. What are the factors that affect the drying rate of a core drier?

- The temperature of the hot air

- The velocity of the hot air

- The moisture content of the product

- The size and shape of the product

4. What are the common problems that can occur with core driers?

- Overdrying

- Underdrying

- Hot spots

- Mechanical problems

5. How can you troubleshoot problems with core driers?

- Check the temperature of the hot air

- Check the velocity of the hot air

- Check the moisture content of the product

- Check the size and shape of the product

- Check for hot spots

- Check for mechanical problems

6. What are the safety precautions that should be taken when operating a core drier?

- Wear appropriate safety gear, such as gloves, safety glasses, and a lab coat.

- Do not operate the drier if it is not in good working order.

- Do not place flammable materials near the drier.

- Do not leave the drier unattended while it is in operation.

7. What are the maintenance procedures that should be followed for a core drier?

- Clean the drier regularly.

- Inspect the drier for any damage.

- Lubricate the drier according to the manufacturer’s instructions.

- Calibrate the drier regularly.

8. What are the energy efficiency features of a core drier?

- Variable speed fans

- Heat recovery systems

- Energy efficient motors

9. What are the latest trends in core drier technology?

- The use of more energy efficient technologies

- The development of new drying methods

- The integration of core driers with other processing equipment

10. What are the challenges facing the core drier industry?

- The increasing demand for energy efficiency

- The development of new drying methods

- The globalization of the core drier market

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Drier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Drier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Core Drier

Core Driers play a crucial role in ensuring the quality of sand used in foundries. Their primary responsibilities include:

1. Drying Sand Cores

Core Driers are responsible for operating and maintaining core drying ovens to remove moisture from sand cores. They monitor the temperature, airflow, and humidity levels to ensure optimal drying conditions.

2. Verifying Core Quality

After drying, Core Driers inspect the cores to verify their dimensional accuracy, hardness, and surface finish. They use specialized measuring tools and gauges to ensure that the cores meet the required specifications.

3. Troubleshooting Drying Issues

Core Driers have a deep understanding of the drying process and are responsible for troubleshooting any issues that may arise. They analyze the drying conditions, identify potential problems, and implement corrective actions to maintain efficient drying.

4. Maintaining Equipment

Core Driers are tasked with maintaining and repairing core drying ovens and related equipment. They perform regular inspections, lubricate moving parts, and replace worn or damaged components to ensure proper functioning.

Interview Tips for Core Drier

To ace an interview for a Core Drier position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the foundry industry by researching their products, services, and market position. This shows that you are eager to learn about the organization and contribute to its success.

2. Highlight Relevant Experience

Emphasize your experience in sand core drying, equipment operation, and quality control. Quantify your accomplishments whenever possible, using specific metrics to showcase your impact.

3. Show Problem-Solving Skills

Interviewers value candidates who can identify and resolve problems effectively. Share examples of how you have troubleshooted drying issues or improved drying processes in previous roles.

4. Prepare for Technical Questions

Review the drying process, equipment specifications, and industry standards. Be prepared to discuss the importance of drying parameters, such as temperature, airflow, and humidity.

5. Emphasize Safety Awareness

Core Driers work in a foundry environment that can involve hazards. Highlight your understanding of safety regulations, personal protective equipment, and emergency procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Drier interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!