Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Core Extruder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Core Extruder so you can tailor your answers to impress potential employers.

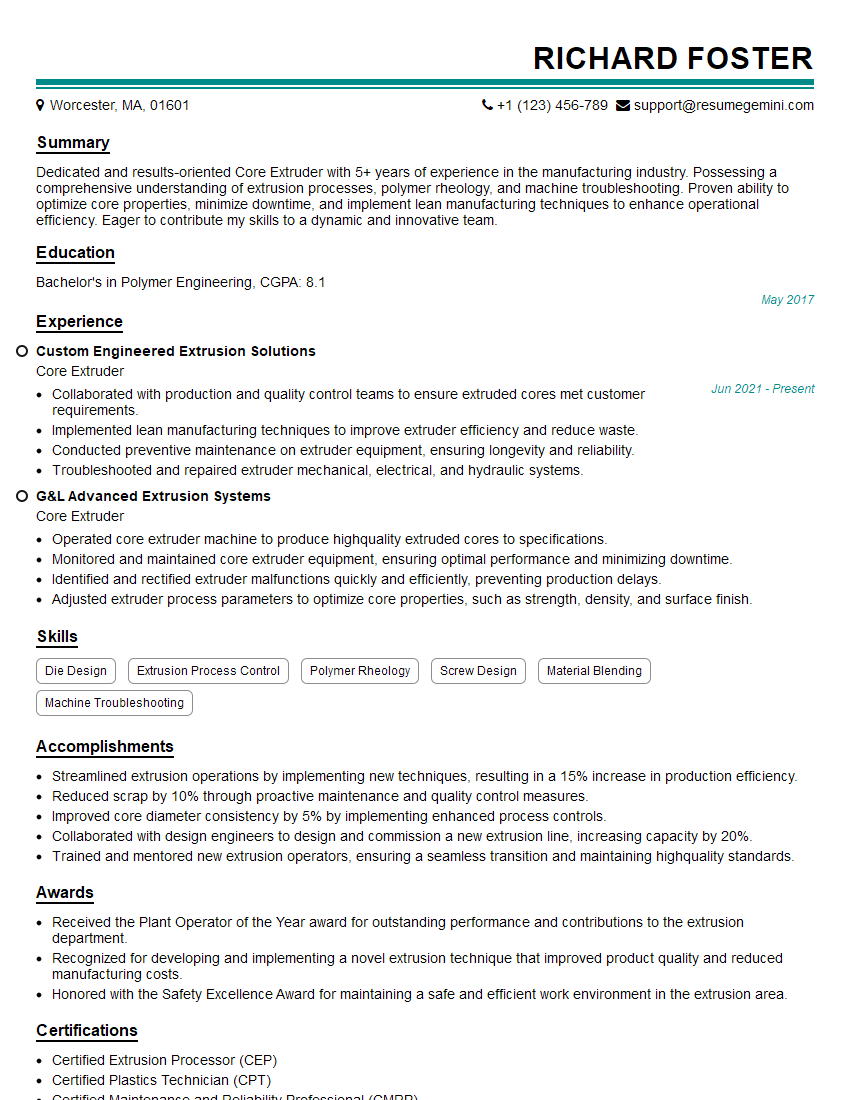

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Extruder

1. How do you ensure the accuracy and precision of the extrusion process?

To ensure accuracy and precision in the extrusion process, I employ several key strategies:

- Calibration and maintenance of equipment: I regularly calibrate and maintain all extrusion equipment, including the extruder, dies, and auxiliary components, to ensure they meet specified tolerances.

- Monitoring of process parameters: I closely monitor critical process parameters such as temperature, pressure, and flow rate using sensors and control systems. Deviations are promptly detected and corrected.

- Statistical process control: I implement statistical process control techniques to identify and eliminate sources of variation in the extrusion process. This allows me to optimize settings and maintain consistent product quality.

2. Describe your experience in optimizing extrusion line performance.

Troubleshooting and Problem-Solving

- I have extensive experience in troubleshooting and resolving extrusion line issues. I can quickly identify the root cause of problems, such as product defects, process inefficiencies, or equipment malfunctions.

- I use analytical tools and techniques to analyze data and determine the best course of action for resolving issues and improving performance.

Process Optimization

- I have successfully implemented process optimization strategies to enhance extrusion line performance. This includes optimizing temperature profiles, reducing pressure fluctuations, and adjusting screw speed and torque.

- Through these optimizations, I have achieved significant improvements in product quality, production efficiency, and energy consumption.

3. How do you handle challenging materials during extrusion?

When working with challenging materials during extrusion, I approach the task strategically:

- Material characterization: I conduct thorough material characterization to understand its properties, behavior, and potential challenges during extrusion.

- Equipment selection and modification: I carefully select and modify extrusion equipment based on the material’s characteristics. This may involve using specialized screws, dies, and other components.

- Process optimization: I optimize extrusion process parameters, such as temperature, pressure, and shear rate, to minimize defects and ensure product quality.

- Collaboration with suppliers: I collaborate closely with material suppliers to gain insights into the material’s behavior and develop effective extrusion strategies.

4. How do you ensure the safety and efficiency of the extrusion process?

Safety and efficiency are paramount in the extrusion process:

- Safety protocols: I strictly adhere to safety protocols, including proper handling of materials, wearing appropriate protective gear, and following lockout/tagout procedures.

- Equipment maintenance: I perform regular equipment maintenance to ensure its safe and efficient operation. This includes cleaning, lubrication, and inspection of critical components.

- Process optimization: I optimize extrusion process parameters to minimize energy consumption, reduce waste, and improve overall efficiency.

- Training and supervision: I provide training and supervision to ensure that operators are knowledgeable about safety procedures and best practices for efficient extrusion.

5. Describe your experience in working with different types of extrusion dies.

Throughout my career, I have worked with a wide range of extrusion dies:

- Flat dies: I have extensive experience in operating flat dies for the production of films, sheets, and panels. I am proficient in setting and adjusting die gaps to achieve desired product dimensions and properties.

- Profile dies: I am also skilled in working with profile dies to create complex shapes and profiles. I understand the principles of die design and can troubleshoot issues related to flow patterns and product defects.

- Co-extrusion dies: I have experience in operating co-extrusion dies to produce multi-layer products. I am knowledgeable about the challenges and techniques involved in co-extrusion, such as layer bonding and interface control.

6. How do you maintain and troubleshoot extrusion equipment?

Maintaining and troubleshooting extrusion equipment are crucial aspects of my role:

- Maintenance: I perform regular maintenance tasks to ensure the equipment is operating at peak performance. This includes cleaning, lubrication, and inspection of components such as the extruder barrel, screws, dies, and pumps.

- Troubleshooting: When issues arise, I use my technical expertise to troubleshoot the equipment quickly and efficiently. I can identify the root cause of problems and implement appropriate solutions to minimize downtime and maintain production.

- Collaboration with technicians: I work closely with maintenance technicians to ensure that repairs and replacements are carried out correctly and in a timely manner.

7. How do you ensure product quality during the extrusion process?

Maintaining product quality is my top priority during the extrusion process:

- Raw material inspection: I inspect incoming raw materials to ensure they meet specifications and are free from contaminants.

- Process monitoring: I continuously monitor extrusion parameters such as temperature, pressure, and flow rate. Deviations from optimal settings are immediately detected and corrected.

- Product testing: I conduct regular product testing to evaluate properties such as dimensions, strength, and appearance. Non-conforming products are identified and rejected.

- Continuous improvement: I am involved in continuous improvement initiatives to enhance product quality and reduce defects.

8. Describe your experience in developing new extrusion processes.

I have played a key role in developing several new extrusion processes:

- Novel die designs: I have designed and implemented innovative die configurations to produce products with unique shapes and properties.

- Optimization of process parameters: I have conducted extensive research to optimize extrusion process parameters for various materials and applications.

- Collaboration with research institutions: I have collaborated with research institutions to develop and evaluate new extrusion technologies.

- Patent applications: I have filed several patents related to my work on extrusion process development.

9. How do you stay up-to-date with the latest advancements in extrusion technology?

Staying up-to-date with the latest advancements in extrusion technology is essential:

- Industry conferences: I regularly attend industry conferences and seminars to learn about new technologies and best practices.

- Technical publications: I subscribe to technical journals and read industry publications to keep abreast of the latest research and developments.

- Networking: I network with other extrusion professionals to exchange knowledge and ideas.

- Continuing education: I pursue continuing education courses and workshops to enhance my skills and knowledge.

10. How do you handle multiple projects and priorities as a Core Extruder?

Managing multiple projects and priorities effectively is crucial in my role as a Core Extruder:

- Prioritization: I prioritize tasks based on their urgency and importance, ensuring that critical projects receive the necessary attention.

- Time management: I effectively manage my time using tools and techniques such as task lists, calendars, and project tracking software.

- Delegation: When appropriate, I delegate tasks to team members to distribute the workload and meet deadlines.

- Communication: I maintain open communication with team members, supervisors, and stakeholders to ensure everyone is informed and aligned.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Extruder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Extruder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Core Extruder is responsible for operating and maintaining core extrusion equipment, ensuring that the production process runs smoothly and efficiently. Key job responsibilities include:

1. Equipment Operation

Operate core extrusion machines and related equipment.

- Monitor machine settings and make necessary adjustments to optimize production.

- Troubleshoot and resolve equipment malfunctions.

- Perform routine maintenance and cleaning of equipment.

2. Production Management

Ensure that production targets are met.

- Plan and schedule production runs.

- Monitor product quality and make necessary adjustments to the process.

- Coordinate with other departments to ensure a smooth flow of materials and finished products.

3. Quality Control

Maintain high standards of product quality.

- Inspect products for defects and take corrective actions.

- Follow quality control procedures and protocols.

- Provide feedback to management on quality issues.

4. Safety and Environment

Adhere to safety regulations and maintain a clean and safe work environment.

- Follow all safety procedures and guidelines.

- Identify and mitigate potential hazards.

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for a Core Extruder position, it is important to prepare thoroughly and highlight your relevant skills and experience. Here are some tips:

1. Research the company and the position

Research the company’s website, social media pages, and industry news to gather information about their core business, values, and recent developments. This will help you understand the company’s culture and align your answers with their needs.

- Tailor your resume and cover letter to the specific requirements of the job.

- Practice answering common interview questions related to your skills and experience.

2. Highlight your technical skills

Emphasize your proficiency in operating and maintaining core extrusion equipment. Describe your experience in troubleshooting and resolving equipment malfunctions, as well as your knowledge of quality control procedures.

- Quantify your accomplishments whenever possible using specific metrics or data points.

- Provide examples of situations where you successfully resolved complex technical issues.

3. Demonstrate your production management abilities

Showcase your skills in planning and scheduling production runs, monitoring product quality, and coordinating with other departments. Highlight your ability to meet production targets and ensure a smooth flow of materials and finished products.

- Describe your experience in using production planning software or other tools.

- Share examples of how you have improved production efficiency or reduced waste.

4. Emphasize your safety and environmental awareness

Core Extruders must prioritize safety and maintain a clean and safe work environment. Emphasize your understanding of safety regulations and your commitment to adhering to them. Describe your experience in identifying and mitigating potential hazards, and your efforts to maintain a clean and organized work area.

- Share your knowledge of relevant safety standards and certifications.

- Provide examples of how you have implemented safety improvements or resolved environmental issues.

5. Prepare questions for the interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions about the company’s growth plans, the challenges the department is facing, and opportunities for professional development.

- Avoid asking generic questions that can be easily answered by researching the company online.

- Ask questions that demonstrate your enthusiasm for the role and your eagerness to contribute to the team.

Next Step:

Now that you’re armed with the knowledge of Core Extruder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Core Extruder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini