Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Core Maker Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

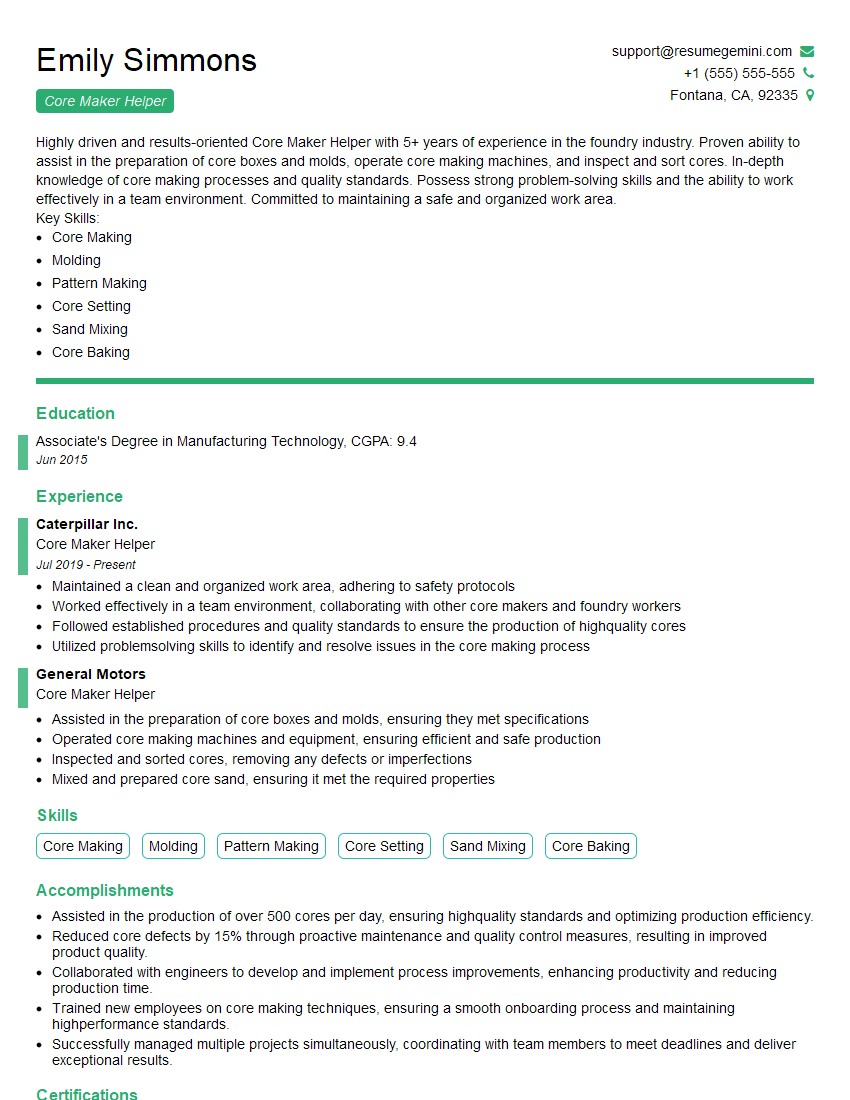

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Maker Helper

1. What are the key responsibilities of a Core Maker Helper?

As a Core Maker Helper, my primary responsibilities include:

- Assisting Core Makers in the production of cores for casting processes.

- Preparing and mixing core sands and binders according to specifications.

2. Describe the core-making process.

Core Box Preparation

- Inspect core boxes for damage or defects.

- Apply release agents to prevent sticking.

Sand Preparation

- Mix core sand with binders and additives to achieve the desired properties.

- Condition the sand by aerating or heating to improve flowability and strength.

Core Production

- Fill the core box with sand and compact it using jolting, ramming, or blowing methods.

- Remove the core from the box and place it on a drying rack.

Core Drying

- Heat the cores in ovens or dryers to remove moisture and strengthen the bond.

- Monitor temperature and time to ensure proper drying.

Core Assembly

- Assemble multiple cores to form complex shapes.

- Secure cores using adhesives or mechanical fasteners.

3. What are the different types of core sands?

Common types of core sands include:

- Green Sand: Moist sand that is used for large, heavy cores.

- Resin Sand: Sand bonded with organic resins for improved strength and precision.

- Oil Sand: Sand bonded with oils for medium-sized cores with good surface finish.

- Shell Sand: Sand coated with a phenolic resin that hardens when heated.

4. How do you ensure the quality of cores?

To ensure core quality, I follow these steps:

- Sand Testing: Check the grain size, moisture content, and strength properties of core sand.

- Core Inspection: Examine cores for defects, such as cracks, voids, or blowholes.

- Dimensional Accuracy: Measure cores to verify that they meet specifications.

- Core Strength Testing: Conduct tests to determine the compressive and tensile strength of cores.

5. What are the safety hazards associated with core making?

The following safety hazards are common in core making:

- Silica Dust: Inhaling silica dust can lead to respiratory problems.

- Chemical Fumes: Binders and release agents release fumes that can cause irritation.

- Heat: Ovens and dryers generate high temperatures.

- Heavy Lifting: Cores can be heavy and require proper lifting techniques.

6. How do you maintain core-making equipment?

Regular maintenance is crucial for efficient core making. I perform the following tasks:

- Cleaning: Remove sand and debris from machines and surfaces.

- Lubrication: Oil moving parts to prevent wear and tear.

- Inspections: Check for loose bolts, worn components, or leaks.

- Repairs: Troubleshoot and repair minor equipment issues promptly.

7. How do you handle scrap cores?

I manage scrap cores responsibly by:

- Sorting: Segregating scrap cores based on sand type and quality.

- Recycling: Reusing suitable scrap cores in the sand mix.

- Disposal: Disposing of non-reusable scrap cores safely and in accordance with environmental regulations.

8. What are the quality control standards for cores?

Cores must meet the following quality standards:

- Dimensional Accuracy: Within specified tolerances.

- Strength: Adequate to withstand casting forces.

- Surface Finish: Free from defects that may affect casting quality.

- Collapsibility: Easily removed from the casting after solidification.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Maker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Maker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Core Maker Helpers assist Core Makers in the production of molds and cores used in metal casting processes. Their primary responsibilities include:

1. Mold and Core Preparation

Assist in preparing molding boxes and core boxes by cleaning, assembling, and securing them.

- Clean and apply release agents to prevent adhesion of the casting material to the mold.

- Assemble and fasten molding boxes to ensure a proper seal during pouring.

2. Sand Mixing and Handling

Operate sand mixers and prepare molding sand according to specified ratios and properties.

- Determine and adjust sand binder ratios to achieve the desired strength and workability.

- Load and unload sand into mixers, ensuring proper mixing time and consistency.

3. Mold and Core Production

Fill molding boxes with prepared sand and compact it using rammers or vibrating equipment.

- Position and secure core prints and inserts into molds to create hollow castings.

- Finish and polish mold surfaces to ensure proper casting results.

4. Core Baking and Finishing

Assist in baking cores in ovens to cure the binders and develop strength.

- Monitor core baking time and temperature to achieve optimal properties.

- Remove baked cores from ovens and inspect them for defects or damage.

5. Safety and Maintenance

Observe and adhere to all safety protocols and regulations.

- Wear appropriate protective gear, including respirators, gloves, and eye protection.

- Maintain a clean and organized work area, minimizing potential hazards.

Interview Tips

To ace the interview for a Core Maker Helper position, candidates should consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends.

- Visit the company website and read industry publications to gain insights.

- Highlight your understanding of the casting process and its applications.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions.

- Use the STAR method (Situation, Task, Action, Result) to describe your experience.

- Emphasize your skills in mold preparation, sand handling, and core production.

3. Highlight Your Physical Capabilities

The job of a Core Maker Helper requires physical stamina.

- Describe your ability to lift heavy objects and work in demanding conditions.

- Mention any relevant experience or training in physical labor.

4. Demonstrate Safety Awareness

Safety is paramount in foundries.

- Discuss your understanding of safety protocols and adherence to regulations.

- Explain how you would handle potential hazards and respond to emergencies.

5. Show Enthusiasm and Trainability

Core Maker Helpers are team players who are eager to learn.

- Express your interest in the casting process and your willingness to contribute.

- Ask questions about the company’s training programs and career advancement opportunities.

Next Step:

Now that you’re armed with the knowledge of Core Maker Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Core Maker Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini