Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Core Winder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Core Winder so you can tailor your answers to impress potential employers.

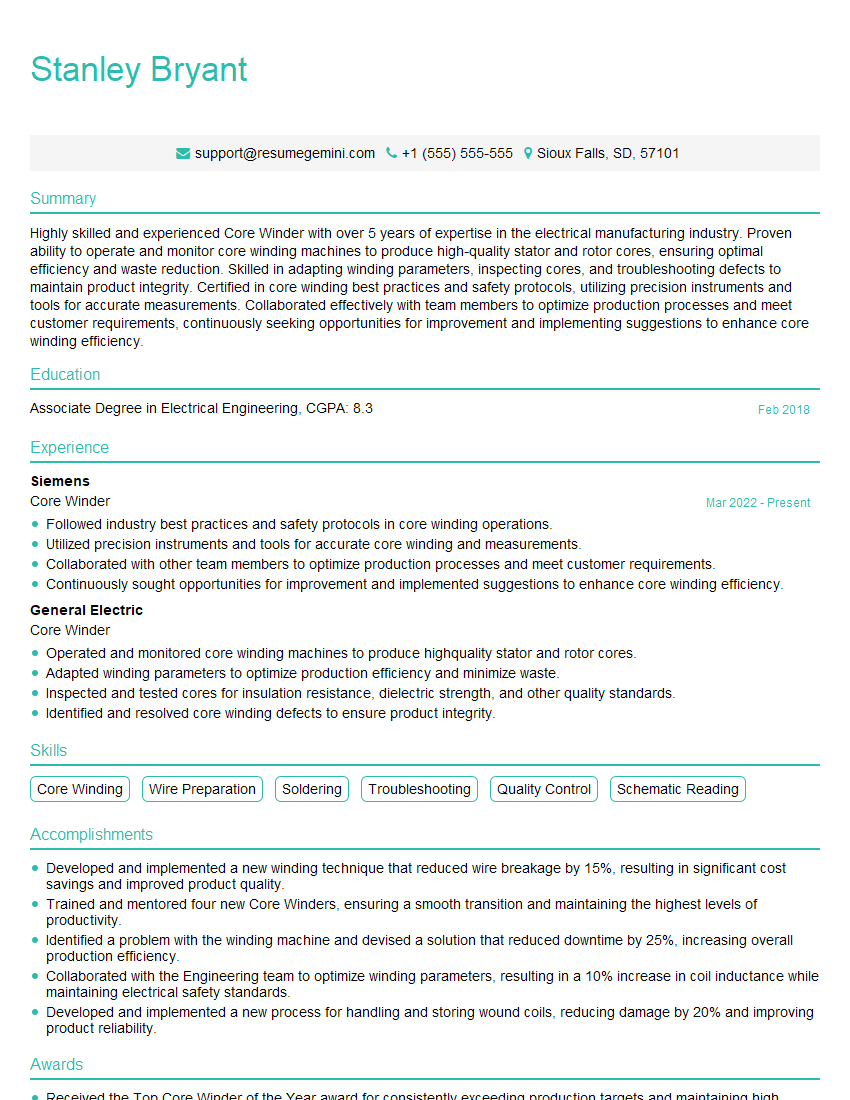

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Winder

1. What are the different types of core winding machines and their applications?

There are various types of core winding machines, each designed for specific applications. Here are some common ones:

- Continuous Winding Machines: Used for high-volume production, these machines continuously wind wire around a rotating core.

- Shuttle Winding Machines: Suitable for winding complex or irregularly shaped cores, these machines use shuttles to insert wire in specific patterns.

- Layer Winding Machines: Used for precise winding of multiple layers of wire, these machines control the pitch and tension of each layer.

- Random Winding Machines: For low-volume production, these machines wind wire randomly around a core, creating a more distributed distribution.

- CNC Winding Machines: Computer-controlled, these machines offer high precision and repeatability in winding complex cores.

2. Describe the process of winding a transformer core.

Insulation

- Apply insulating tape or varnish to the core to prevent short circuits between windings.

Primary Winding

- Wind the primary coil onto the core according to the specified turns and layer configuration.

- Secure the winding with tape or adhesives.

Secondary Winding (if applicable)

- Apply insulation between the primary and secondary windings.

- Wind the secondary coil onto the core.

Finishing

- Insulate the outer winding with tape or varnish.

- Pot or encapsulate the core to protect the windings.

3. How do you troubleshoot winding defects and ensure the quality of wound cores?

To troubleshoot winding defects and ensure quality, I follow these steps:

- Visual Inspection: Check for loose connections, broken wires, or any physical damage.

- Electrical Testing: Perform continuity tests, insulation resistance tests, and turns ratio tests to identify electrical faults.

- Core Testing: Use core testing equipment to measure magnetic properties and identify core defects.

- Process Validation: Review winding parameters, machine settings, and material specifications to identify potential issues.

- Corrective Actions: Implement corrective actions based on the identified defects, such as rewinding, repairing, or replacing components.

4. What are the safety precautions to observe when working with core winding machines?

For safe operation of core winding machines, I adhere to the following precautions:

- Proper Training: Receive comprehensive training on the specific machine and its operation.

- PPE: Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Machine Guarding: Ensure that all machine guards and safety devices are in place and functional.

- Lockout/Tagout: Follow proper lockout/tagout procedures when servicing or cleaning the machine.

- Hazardous Materials: Handle flammable or toxic materials with care and follow safety protocols.

5. What are the different types of wire used in core winding and their properties?

There are various types of wire used in core winding, each with its own properties:

- Copper Wire: High conductivity, good solderability, and easy to work with.

- Aluminum Wire: Lighter than copper, but less conductive and more brittle.

- Litz Wire: Made of multiple strands twisted together, reduces skin effect and improves high-frequency performance.

- Enameled Wire: Insulated with a thin layer of enamel, providing electrical isolation.

- Film-Insulated Wire: Insulated with a polymer film, offering higher temperature resistance and flexibility.

6. How do you maintain and calibrate core winding machines for optimal performance?

To maintain and calibrate core winding machines, I follow these steps:

- Regular Cleaning: Remove dust, debris, and wire clippings to prevent machine malfunctions.

- Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Calibration: Use precision measuring equipment to calibrate the machine’s tension, pitch, and winding parameters.

- Diagnostics: Perform diagnostic tests to identify potential issues and take preventive measures.

- Record Keeping: Maintain records of maintenance and calibration activities for traceability and quality control.

7. What types of quality control measures are implemented in core winding operations?

To ensure the quality of core windings, I implement the following measures:

- Visual Inspection: Inspect windings for defects, such as loose connections or insulation damage.

- Electrical Testing: Conduct electrical tests, including continuity, insulation resistance, and turns ratio tests.

- Dimensional Inspection: Measure winding dimensions to ensure they meet specifications.

- Sample Testing: Test a representative sample of windings to assess overall quality.

- Process Control: Monitor winding parameters, such as tension, pitch, and speed.

8. What are the common challenges faced in core winding and how do you address them?

Some common challenges in core winding include:

- Wire Breaks: Ensure proper tension control, adjust winding parameters, and inspect wire for defects.

- Insulation Damage: Use appropriate insulation materials, adjust winding tension, and handle cores carefully.

- Core Defects: Inspect cores for imperfections, adjust winding parameters, and consult with core manufacturers.

- Machine Malfunctions: Perform regular maintenance, calibrate machines, and troubleshoot issues promptly.

- Quality Control: Implement robust quality control measures, train operators, and monitor processes continuously.

9. How do you stay up-to-date with the latest advancements in core winding technology?

To stay up-to-date, I engage in the following activities:

- Attend Industry Events: Participate in conferences, workshops, and exhibitions to learn about new technologies.

- Read Technical Publications: Subscribe to industry journals, magazines, and online resources.

- Networking: Connect with professionals in the field to exchange knowledge and experiences.

- Online Learning: Enroll in online courses or webinars to enhance my skills.

- Research and Development: Actively seek opportunities to contribute to or stay informed about ongoing research in core winding.

10. What are your strengths and weaknesses as a Core Winder?

Strengths:

- Technical Expertise: Proficient in core winding techniques, machine operation, and quality control.

- Quality Orientation: Committed to producing high-quality windings that meet customer specifications.

- Attention to Detail: Meticulous and detail-oriented, ensuring accuracy and precision in winding.

- Troubleshooting Skills: Able to identify and resolve winding defects efficiently.

- Teamwork and Communication: Collaborates effectively with colleagues and communicates technical information clearly.

Weaknesses:

- Limited Experience with Specific Equipment: Limited experience operating certain specialized core winding machines.

- Developing Leadership Skills: Aspiring to develop stronger leadership abilities to guide and mentor others in the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Core Winder plays a pivotal role in the manufacturing process by operating machinery to wind and insulate coils, known as cores, used in electrical transformers and other electrical devices. This skilled professional ensures that the cores meet precise specifications and quality standards to guarantee optimal performance and safety of electrical systems. Let’s delve into the core responsibilities of a Core Winder:

1. Core Winding and Assembly

The primary task of a Core Winder is to meticulously wind coils of copper or aluminum wire onto a core, forming the foundation of electrical transformers and other electrical components. They must adhere to precise winding patterns and maintain consistent tension to ensure proper insulation and electrical performance.

- Expertly operate winding machines to coil wire onto the core according to specified winding patterns.

- Control the tension of the wire during winding to achieve optimal insulation and electrical properties.

- Ensure the proper alignment and spacing of turns to prevent short circuits and ensure efficient operation.

2. Insulation and Finishing

After winding, Core Winders are responsible for applying insulation to the coils to protect them from electrical breakdown and ensure safe operation. They also perform finishing touches to enhance the durability and performance of the cores.

- Apply insulation materials, such as varnish or epoxy, to the wound coils to prevent electrical shorts.

- Perform finishing operations, such as taping or heat-treating, to ensure the integrity and longevity of the cores.

- Inspect the finished cores for quality and conformity to specifications before packaging and shipment.

3. Machine Maintenance and Troubleshooting

To maintain optimal production efficiency, Core Winders are expected to perform basic maintenance on the winding machines they operate. They also troubleshoot and resolve minor issues to minimize downtime and ensure smooth production flow.

- Conduct routine maintenance tasks, such as lubrication, cleaning, and minor repairs, to keep machines in good working order.

- Troubleshoot and resolve common winding machine issues to minimize downtime and maintain production schedules.

- Follow standard operating procedures and safety protocols to ensure the safe and efficient operation of winding machinery.

4. Quality Assurance and Improvement

Core Winders contribute to the overall quality of electrical components by adhering to strict quality standards and actively seeking opportunities for improvement. They monitor the winding process to identify and correct any deviations from specifications.

- Monitor the winding process to ensure compliance with quality standards and specifications.

- Identify and correct deviations in winding patterns or insulation application to prevent defects.

- Suggest improvements to the winding process or machine performance to enhance efficiency and quality.

Interview Preparation Tips

To ace your Core Winder interview, it’s essential to prepare thoroughly and showcase your skills and experience effectively. Here are some valuable tips to help you shine during the interview:

1. Research the Company and Position

Demonstrate your interest in the organization and the Core Winder position by researching their website, LinkedIn page, and industry news. Understand their products, services, and company culture to tailor your answers accordingly.

- Visit the company website to learn about their history, values, and recent projects.

- Review the job description meticulously to identify the key qualifications and skills required for the role.

- Explore industry publications and online forums to gain insights into the latest trends and best practices in core winding.

2. Highlight Relevant Skills and Experience

During the interview, focus on showcasing your technical abilities, experience in core winding, and transferable skills that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Emphasize your expertise in operating core winding machines and applying insulation materials.

- Describe specific projects where you successfully wound and assembled electrical cores to meet specifications.

- Highlight your ability to maintain and troubleshoot winding machinery to minimize downtime.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your responses. This will help you articulate your skills, experience, and aspirations clearly and confidently.

- Tell me about your experience in core winding, and what sets you apart from other candidates.

- Describe a challenging situation you faced while winding cores, and how you overcame it.

- How do you ensure the quality and accuracy of your work as a Core Winder?

4. Ask Meaningful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the opportunity. Prepare a few questions to ask the interviewer about the company, the position, or the industry.

- What are the company’s growth plans and how does this position contribute to those goals?

- Can you provide more details about the core winding process and the technologies used?

- What opportunities are there for professional development and career advancement within the organization?

5. Follow Up Professionally

After the interview, follow up with a thank-you note expressing your appreciation for the opportunity. Reiterate your interest in the position and highlight any key points you want to emphasize. This step shows your professionalism and keenness on the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!