Are you gearing up for a career in Core Winder Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Core Winder Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

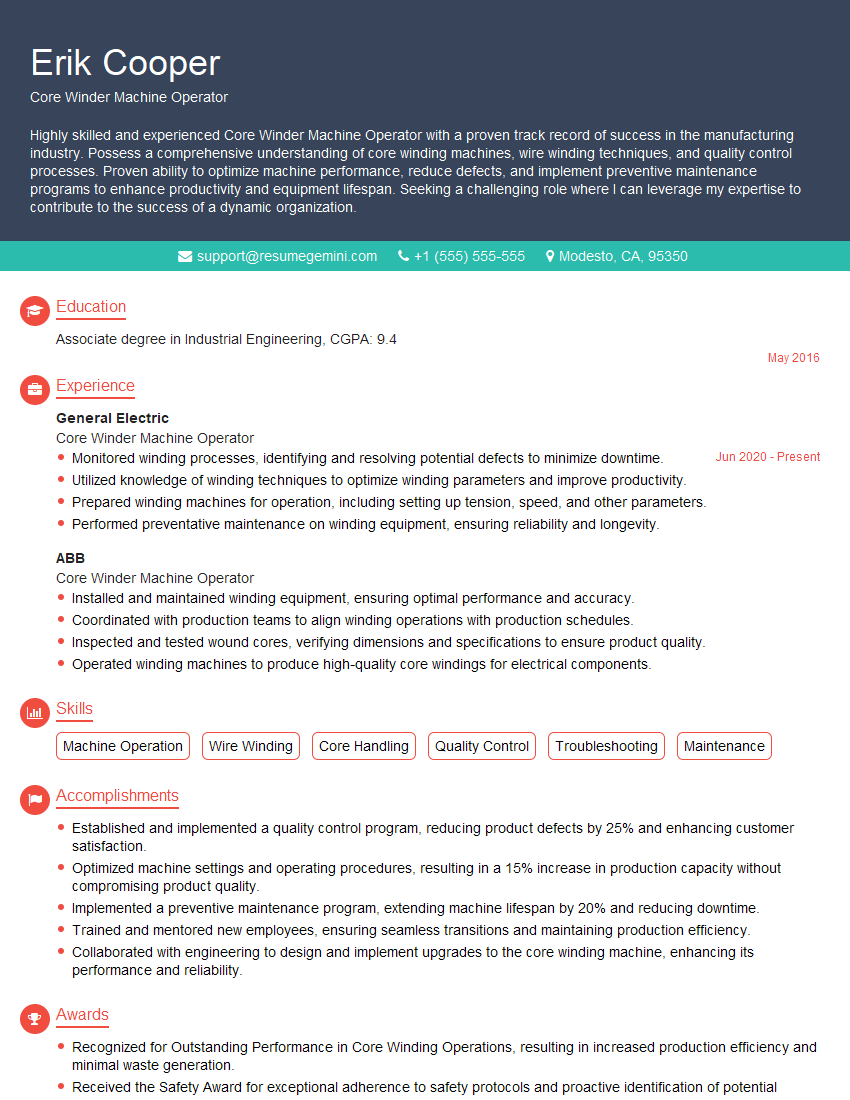

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Core Winder Machine Operator

1. Explain the process of core winding on a core winding machine?

The core winding process on a core winding machine involves the following steps:

- Mounting the core: The core is mounted on the winding machine’s mandrel.

- Feeding the wire: The wire is fed through the tension control device and onto the core.

- Winding the wire: The winding head rotates the core while the wire is wound onto it in a specified pattern.

- Applying insulation: Insulation is applied between layers of wire to prevent electrical shorts.

- Finishing the winding: The winding is completed, and the ends of the wire are secured.

2. What are the different types of core winding machines and their applications?

Manual core winding machines

- Used for small-scale production and prototyping.

- Require manual operation, making them labor-intensive.

Semi-automatic core winding machines

- Combine manual and automated operations.

- Faster than manual machines but less precise than fully automatic machines.

Fully automatic core winding machines

- Fully automated, reducing labor costs and increasing efficiency.

- Can handle complex winding patterns and produce high-quality cores.

3. How do you ensure the quality of the wound cores?

I ensure the quality of the wound cores through the following measures:

- Visual inspection: Inspecting the cores for any visible defects, such as loose windings or insulation damage.

- Electrical testing: Conducting electrical tests to verify the continuity and insulation resistance of the windings.

- Dimensional measurements: Measuring the dimensions of the cores to ensure they meet specifications.

- Adhering to quality standards: Following established quality standards and procedures to ensure consistent output.

4. What are the common troubleshooting techniques for core winding machines?

Common troubleshooting techniques for core winding machines include:

- Wire tension issues: Adjusting the tension control device to resolve wire breakage or loose windings.

- Insulation problems: Identifying and repairing insulation damage to prevent electrical shorts.

- Mechanical faults: Inspecting and replacing worn or damaged parts, such as bearings or gears.

- Electrical malfunctions: Troubleshooting electrical components, such as motors or sensors, to restore functionality.

5. How do you maintain and calibrate a core winding machine?

To maintain and calibrate a core winding machine, I perform the following tasks:

- Regular cleaning: Cleaning the machine to remove dust, debris, and wire clippings.

- Lubrication: Lubricating moving parts to ensure smooth operation and prevent wear.

- Calibration: Using calibration tools to adjust the machine’s settings for accurate winding.

- Preventive maintenance: Conducting regular inspections and replacing worn or damaged parts to prevent breakdowns.

6. What steps do you take to minimize waste and optimize material usage in core winding?

To minimize waste and optimize material usage in core winding, I implement the following practices:

- Efficient winding patterns: Utilizing winding patterns that minimize wire usage and reduce scrap.

- Material planning: Accurately calculating wire requirements to avoid over-ordering and waste.

- Reuse of scrap wire: Repurposing short wire pieces for smaller windings or non-critical applications.

- Recycling: Participating in recycling programs to dispose of waste materials responsibly.

7. How do you handle production deadlines and ensure on-time delivery?

I effectively manage production deadlines and ensure on-time delivery through the following approaches:

- Production planning: Scheduling production tasks and allocating resources to meet deadlines.

- Monitoring progress: Regularly tracking production progress and identifying potential bottlenecks.

- Prioritizing tasks: Focusing on critical tasks first to avoid delays in key processes.

- Contingency planning: Developing backup plans and alternative solutions to address unexpected challenges.

8. Can you describe the safety precautions you observe while operating a core winding machine?

I prioritize safety by adhering to the following precautions while operating a core winding machine:

- Machine guarding: Ensuring that all moving parts and exposed wires are properly guarded to prevent injuries.

- Personal protective equipment: Wearing appropriate PPE, such as safety glasses, gloves, and hearing protection.

- Electrical safety: Following electrical safety protocols, including lockout/tagout procedures during maintenance.

- Ergonomic practices: Maintaining proper posture and using ergonomic tools to reduce the risk of musculoskeletal injuries.

9. How do you stay updated with the latest technologies and advancements in core winding?

I keep abreast of the latest technologies and advancements in core winding through the following methods:

- Industry publications: Reading trade magazines, journals, and online articles.

- Conferences and workshops: Attending industry events to learn from experts and network with peers.

- Manufacturer updates: Reviewing technical bulletins and product updates from core winding machine manufacturers.

- Online forums and discussions: Participating in online communities to exchange knowledge and stay informed about emerging trends.

10. What are your strengths and weaknesses as a Core Winder Machine Operator?

My strengths as a Core Winder Machine Operator include:

- Technical expertise: Possessing a strong understanding of core winding principles and machine operation.

- Attention to detail: Meticulously following winding patterns and specifications to ensure quality.

- Problem-solving skills: Quickly identifying and resolving machine issues to maintain productivity.

- Teamwork and communication: Collaborating effectively with colleagues and supervisors to achieve production goals.

As for my weaknesses, I am actively working on improving my:

- Speed: Increasing my winding speed while maintaining accuracy and quality.

- Efficiency: Optimizing my workflow to minimize waste and maximize productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Core Winder Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Core Winder Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Core Winder Machine Operators are responsible for operating and maintaining core winding machines that create cylindrical or rectangular cores used in electrical transformers, motors, generators, and other electrical components. Here are the key responsibilities associated with this role:

1. Machine Operation

Operate core winding machines to manufacture cores of various sizes and specifications:

- Set up and adjust machine parameters based on production orders.

- Monitor the winding process and make necessary adjustments to ensure accurate winding and tension.

- Unload finished cores from the machine and inspect them for defects.

2. Machine Maintenance

Perform regular maintenance and troubleshooting tasks to ensure optimal machine performance:

- Inspect and clean machine components, including rollers, guides, and tensioners.

- Lubricate moving parts and replace worn or damaged components.

- Troubleshoot and resolve machine malfunctions or breakdowns to minimize production downtime.

3. Material Handling

Handle and move raw materials and finished cores safely and efficiently:

- Load and unload materials such as wire, insulation, and core boards onto the machine.

- Stack and store finished cores in designated areas.

- Dispose of scrap materials and waste generated during the winding process.

4. Quality Control

Inspect and measure finished cores to ensure they meet specifications:

- Check dimensions, shape, and insulation integrity of cores.

- Conduct electrical tests to verify the performance and quality of the cores.

- Report any non-conforming cores to supervisors for corrective action.

Interview Tips

To prepare effectively for an interview as a Core Winder Machine Operator, it’s essential to showcase your skills, experience, and knowledge in core winding machine operation and maintenance. Here are some interview preparation tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific role you’re applying for. This will help you understand the company’s values, industry, and the requirements of the position. Emphasize how your skills and experience align with the company’s needs in the interview.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills and experience. Some examples include:

- “Describe your experience operating core winding machines and the types of cores you have produced.”

- “How do you ensure the accuracy and quality of the cores you wind?”

- “Explain how you troubleshoot and resolve machine malfunctions.”

3. Showcase Your Maintenance Skills

Highlight your knowledge and experience in performing maintenance tasks on core winding machines. Explain how you ensure the optimal performance of the equipment and minimize downtime. Mention any specific tools or techniques you are proficient in.

4. Emphasize Safety and Attention to Detail

In this role, safety and attention to detail are crucial. Emphasize your commitment to following safety protocols and maintaining a clean and organized work area. Explain how you ensure the accuracy of your work and identify and correct any potential issues.

5. Be Prepared to Discuss Your Work Ethic

Core Winder Machine Operators often work in fast-paced production environments. Be prepared to discuss your work ethic and how you handle pressure and deadlines. Highlight your ability to work independently and as part of a team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Core Winder Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.