Are you gearing up for an interview for a Coremaking Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coremaking Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

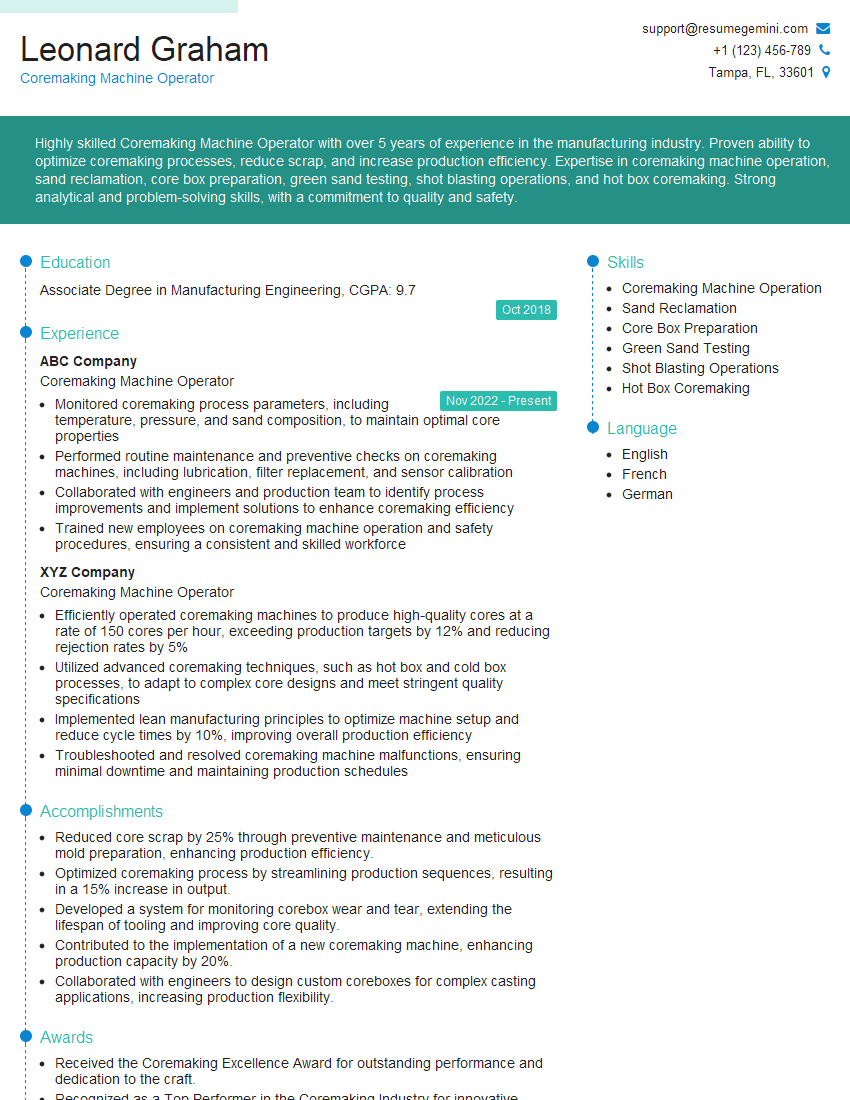

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coremaking Machine Operator

1. What are the key steps involved in the coremaking process?

The key steps involved in the coremaking process include:

- Preparing the sand mix

- Creating the core box

- Loading the sand mix into the core box

- Compacting the sand mix

- Curing the core

- Removing the core from the core box

- Inspecting the core

2. What are the different types of coremaking machines?

The different types of coremaking machines include:

- Blowing machines

- Hot box machines

- Cold box machines

- Shell core machines

- No-bake machines

3. What are the advantages and disadvantages of using a blowing machine?

The advantages of using a blowing machine include:

- High production rates

- Good dimensional accuracy

- Low tooling costs

The disadvantages of using a blowing machine include:

- Limited core size

- Noise and dust

- Can only be used with certain types of sand mixes

4. What is the difference between a cold box core and a hot box core?

Cold box cores are made using a resin that is cured at room temperature, while hot box cores are made using a resin that is cured at elevated temperatures.

Cold box cores have a longer bench life than hot box cores, but hot box cores have better dimensional accuracy and strength.

5. What are the safety precautions that must be taken when operating a coremaking machine?

The safety precautions that must be taken when operating a coremaking machine include:

- Wearing appropriate personal protective equipment

- Following the manufacturer’s operating instructions

- Keeping the machine clean and free of debris

- Inspecting the machine regularly for any damage

- Never operating the machine if it is damaged

6. What are the common troubleshooting tips for coremaking machines?

Common troubleshooting tips for coremaking machines include:

- Checking the air pressure

- Checking the sand mix

- Inspecting the core box for any damage

- Checking the curing cycle

- Calibrating the machine

7. What are the different skills and qualifications required to be a Coremaking Machine Operator?

The different skills and qualifications required to be a Coremaking Machine Operator include:

- A high school diploma or equivalent

- Experience operating coremaking machines

- Knowledge of coremaking processes

- Ability to read and interpret blueprints

- Ability to work independently and as part of a team

- Physical ability to lift heavy objects

8. What is your experience with different types of coremaking machines?

I have experience operating a variety of coremaking machines, including blowing machines, hot box machines, cold box machines, shell core machines, and no-bake machines.

I am familiar with the different types of sand mixes used in coremaking, and I can adjust the machine settings to produce cores that meet the required specifications.

9. What are some of the challenges you have faced in your previous role as a Coremaking Machine Operator?

One of the challenges I have faced in my previous role as a Coremaking Machine Operator is producing cores that meet the required dimensional accuracy.

To overcome this challenge, I have worked closely with the quality control department to develop a process that ensures that all cores meet the required specifications.

10. What are your goals for your career as a Coremaking Machine Operator?

My goals for my career as a Coremaking Machine Operator are to become a highly skilled and experienced operator.

I am also interested in learning about new coremaking technologies and developing new ways to improve the efficiency of the coremaking process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coremaking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coremaking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coremaking Machine Operators are responsible for the operation, maintenance, and repair of coremaking machines. They work under the supervision of a foundry supervisor and are required to have a thorough understanding of the coremaking process and the equipment used.

1. Operate Coremaking Machine

Coremaking machine operators are responsible for the day-to-day operation of coremaking machines. This includes:

- Setting up the machine

- Loading the machine with sand

- Starting the machine

- Monitoring the machine during operation

- Stopping the machine

- Unloading the machine

2. Maintain Coremaking Machine

Coremaking machine operators are also responsible for the maintenance of coremaking machines. This includes:

- Lubricating the machine

- Checking the machine for wear and tear

- Making minor repairs

- Reporting major repairs to the foundry supervisor

3. Repair Coremaking Machine

Coremaking machine operators are also responsible for the repair of coremaking machines. This includes:

- Troubleshooting the machine

- Replacing worn or damaged parts

- Reassembling the machine

- Testing the machine

4. Other Duties

In addition to the above, coremaking machine operators may also be responsible for:

- Cleaning the work area

- Assisting other foundry workers

- Working overtime

Interview Tips

Interviewing for a Coremaking Machine Operator position can be a daunting task, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go on an interview, it is important to do your research on the company and the position. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

- Review the job description

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with coremaking machines?

- How do you troubleshoot a coremaking machine?

3. Be Enthusiastic and Professional

First impressions matter. When you go on an interview, it is important to be enthusiastic and professional. This will show the interviewer that you are interested in the position and that you are a hard worker.

- Dress appropriately

- Be on time for your interview

- Make eye contact with the interviewer

- Be polite and respectful

4. Follow Up

After your interview, it is important to follow up with the interviewer. This will show the interviewer that you are still interested in the position and that you are serious about your application.

- Send a thank-you note

- Call the interviewer to check on the status of your application

Next Step:

Now that you’re armed with the knowledge of Coremaking Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Coremaking Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini