Are you gearing up for an interview for a Coreroom Foundry Laborer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Coreroom Foundry Laborer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

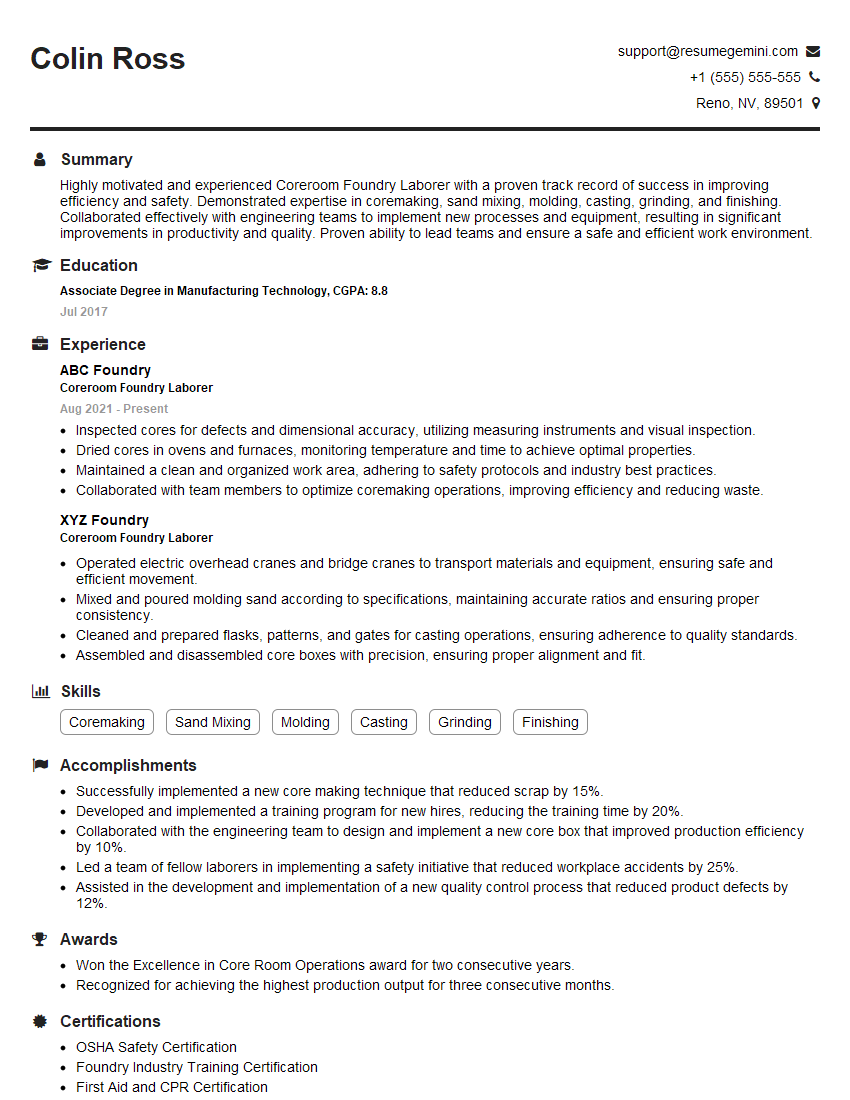

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Coreroom Foundry Laborer

1. What are the key responsibilities of a Coreroom Foundry Laborer?

In my role as a Coreroom Foundry Laborer, I would be responsible for a variety of tasks, including:

- Preparing and mixing sand and resin mixtures for the production of molds and cores.

- Operating core-making machines, such as core blowers and core shooters.

- Setting up and maintaining work areas, including cleaning and lubricating equipment.

- Inspecting finished cores for defects and ensuring they meet quality standards.

- Performing quality control checks on raw materials and finished products.

- Adhering to safety protocols and regulations.

- Assisting with the maintenance and repair of equipment.

2. How do you ensure the production of high-quality cores?

Inspecting Raw Materials

- Verifying the quality and consistency of sand, resin, and other materials.

- Conducting tests to ensure materials meet specifications.

Controlling Process Parameters

- Monitoring and adjusting temperature, pressure, and other variables during core production.

- Following established procedures and quality control standards.

Conducting Regular Inspections

- Visually inspecting cores for defects, such as cracks, voids, and non-uniformity.

- Using measuring tools to ensure cores meet dimensional requirements.

3. What safety precautions should be taken when working in a foundry environment?

To ensure a safe working environment, I would prioritize the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator.

- Following established safety procedures for operating machinery and handling hazardous materials.

- Maintaining a clean and organized work area to minimize tripping and falling hazards.

- Being aware of potential hazards, such as hot surfaces, moving machinery, and hazardous chemicals.

- Reporting any unsafe conditions or incidents to supervisors immediately.

4. How do you handle and store raw materials safely?

Safe handling and storage of raw materials are crucial to prevent accidents and maintain quality:

- Properly labeling and identifying all materials.

- Storing materials in designated areas to avoid contamination.

- Using appropriate containers and equipment to prevent spills and leaks.

- Following manufacturer’s instructions for handling and storage to maintain material integrity.

- Rotating stock to prevent materials from becoming outdated.

5. How do you troubleshoot common issues that may arise during core production?

Cracked or Broken Cores

- Checking for insufficient curing time.

- Adjusting temperature and pressure settings.

- Inspecting for damage to core boxes.

Voids or Gas Pockets

- Ensuring proper mixing of sand and resin.

- Eliminating air pockets during core forming.

- Adjusting ventilation to prevent excessive gas buildup.

Dimensional Inaccuracies

- Verifying the accuracy of core boxes and patterns.

- Calibrating measuring equipment regularly.

- Making adjustments to process parameters, such as temperature and pressure.

6. What is your experience with quality control procedures in a foundry setting?

In my previous role, I was responsible for implementing and maintaining quality control procedures:

- Establishing clear quality standards and specifications.

- Conducting regular inspections of raw materials and finished products.

- Maintaining records of inspection results and corrective actions.

- Working with production staff to identify and address quality issues.

- Collaborating with customers to ensure product quality meets their requirements.

7. How do you ensure the efficient operation of core-making equipment?

Regular Maintenance

- Following manufacturer’s maintenance schedules.

- Cleaning and lubricating equipment regularly.

- Inspecting equipment for wear and tear.

Troubleshooting and Repair

- Identifying and resolving minor issues promptly.

- Reporting major issues to supervisors for timely repair.

- Collaborating with maintenance technicians to ensure efficient repairs.

Process Optimization

- Adjusting process parameters to improve efficiency.

- Minimizing downtime through effective planning and scheduling.

- Implementing lean manufacturing techniques to reduce waste and improve productivity.

8. What is your understanding of the different types of core-making processes?

The core-making processes I am familiar with include:

- Cold box process: Using a chemical binder that cures at room temperature.

- Hot box process: Using a binder that requires heat to cure.

- Shell molding process: Creating thin, hard shells.

- Investment casting process: Using wax patterns to create intricate cores.

- 3D printing process: Producing cores using additive manufacturing.

9. How do you prioritize tasks and manage your time effectively in a fast-paced foundry environment?

To manage my time effectively, I prioritize tasks based on urgency and importance:

- Creating a daily or weekly schedule to plan my activities.

- Breaking down large tasks into smaller, manageable ones.

- Delegating tasks to colleagues when appropriate.

- Minimizing distractions and interruptions during focused work periods.

- Seeking support from supervisors or team members when needed.

10. How do you stay updated on the latest industry trends and advancements in core-making technology?

I stay informed about industry trends and advancements through the following methods:

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Participating in online forums and discussion groups.

- Consulting with equipment manufacturers and suppliers.

- Networking with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Coreroom Foundry Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Coreroom Foundry Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Coreroom Foundry Laborers are responsible for various tasks within a foundry environment. Their duties involve:

1. Coremaking Process

Execute coremaking process, including core setting, blowing, and finishing.

- Set up and operate coremaking machines to produce sand cores for metal castings.

- Inspect cores for defects and ensure they meet quality standards.

- Clean and maintain coremaking equipment.

2. Material Handling

Manage material handling, including sand preparation, core storage, and waste disposal.

- Prepare sand mixtures for coremaking.

- Store and organize cores in designated areas.

- Dispose of waste materials safely and in compliance with environmental regulations.

3. Equipment Maintenance

Perform equipment maintenance and repairs to ensure smooth operations.

- Inspect and maintain foundry equipment, such as core blowers, mixers, and conveyors.

- Conduct routine repairs and troubleshoot equipment issues.

- Keep maintenance records and report equipment status to supervisors.

4. Safety and Compliance

Adhere to safety regulations, wear appropriate protective gear, and maintain a clean and organized work area.

- Follow established safety protocols and use personal protective equipment.

- Maintain a safe and efficient work area.

- Report any safety hazards or concerns to supervisors.

Interview Tips

To prepare for your Coreroom Foundry Laborer interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the foundry’s history, values, and products. Understand the specific responsibilities and qualifications required for the Coreroom Foundry Laborer role.

- Visit the company website and social media pages.

- Review the job description thoroughly.

- Prepare questions about the company and the position.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience in foundry operations, particularly in coremaking, material handling, and equipment maintenance. Showcase your skills in following safety protocols and maintaining a clean work environment.

- Quantify your accomplishments using specific examples.

- Use action verbs to describe your responsibilities.

- Tailor your resume and cover letter to highlight relevant experience.

3. Demonstrate Strong Work Ethic and Safety Consciousness

Convey your willingness to work hard in a physically demanding environment. Emphasize your commitment to safety and your understanding of foundry hazards. Highlight any certifications or training you have related to safety protocols.

- Provide examples of situations where you prioritized safety.

- Explain how you handle physically challenging tasks.

- Describe your knowledge of foundry safety regulations.

4. Prepare for Common Interview Questions

Anticipate common interview questions related to your experience, qualifications, and motivations. Practice your responses to ensure clarity and conciseness.

- Prepare an answer to “Tell me about yourself and your experience in foundry operations.”

- Practice answering questions about your safety knowledge and commitment.

- Consider questions about your ability to work in a team environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Coreroom Foundry Laborer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!