Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cork Insulation Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

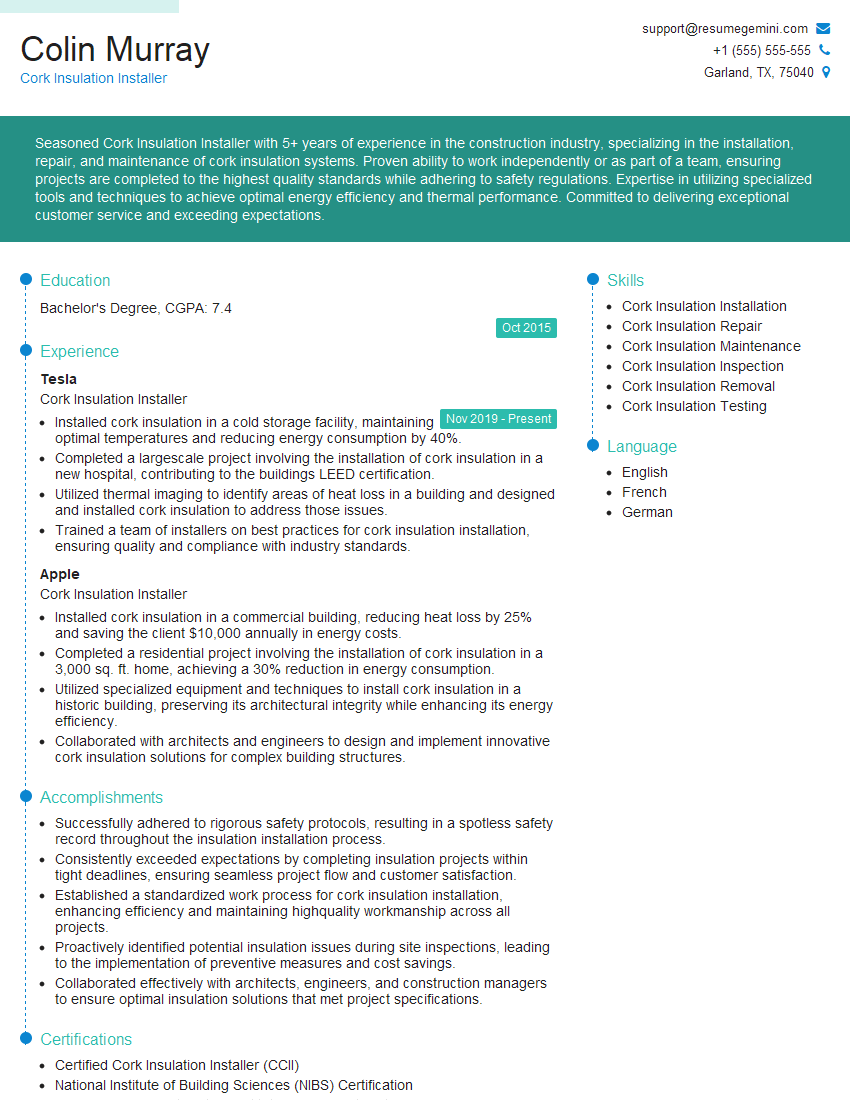

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cork Insulation Installer

1. What are the key considerations when selecting the right type of cork insulation for a specific application?

When selecting the right type of cork insulation for a specific application, key considerations include:

- Thermal Resistance: The R-value of the insulation, which measures its ability to resist heat flow.

- Moisture Resistance: The insulation’s ability to withstand moisture without losing its insulating properties.

- Fire Resistance: The insulation’s ability to resist fire and prevent the spread of flames.

- Acoustic Properties: The insulation’s ability to absorb and reduce sound.

- Environmental Impact: The sustainability and environmental friendliness of the insulation material.

2. Explain the different methods used to install cork insulation and their respective advantages and disadvantages.

Adhesive Application

- Advantages: Easy installation, suitable for flat surfaces, creates a strong bond.

- Disadvantages: Can be time-consuming, requires specialized adhesive.

Mechanical Fasteners

- Advantages: Secure installation, suitable for irregular surfaces, allows for easy removal.

- Disadvantages: Can create thermal bridges, requires drilling into surfaces.

Spray Application

- Advantages: Conforms to complex shapes, fills voids, provides a seamless finish.

- Disadvantages: Requires specialized equipment, can be messy, may not be suitable for certain applications.

3. Describe the proper techniques for sealing and finishing cork insulation to ensure optimal performance.

Proper sealing and finishing of cork insulation involve:

- Seaming: Overlapping insulation panels by 2-3 inches and sealing the joints with cork tape or mastic to prevent air leakage.

- Perimeter Sealing: Sealing the edges of the insulation with caulk or expanding foam to prevent heat loss.

- Vapor Barrier: Installing a vapor barrier on the warm side of the insulation to prevent moisture migration.

- Surface Treatment: Applying a protective coating, such as paint or sealant, to enhance durability and moisture resistance.

4. What are the common challenges encountered during cork insulation installation, and how do you address them?

Common challenges include:

- Uneven Surfaces: Using mechanical fasteners or spray application to accommodate irregular surfaces.

- Moisture: Ensuring proper sealing and vapor barrier installation to prevent moisture absorption.

- Fire Safety: Selecting fire-resistant cork insulation and following installation guidelines to meet building codes.

- Thermal Bridging: Avoiding contact between insulation and conductive materials to prevent heat loss.

5. Explain the importance of regular maintenance and inspection of cork insulation and describe the recommended maintenance schedule.

Regular maintenance and inspection of cork insulation are crucial for ensuring its long-term performance. The recommended schedule includes:

- Visual Inspection: Checking for damage, loose seals, or moisture accumulation.

- Thermal Imaging: Identifying areas of heat loss or thermal bridging.

- Moisture Testing: Using moisture meters to detect moisture levels within the insulation.

6. How do you ensure quality control during cork insulation installation to meet industry standards and client expectations?

Quality control measures include:

- Material Inspection: Verifying the quality and specifications of the cork insulation materials.

- Installation Verification: Checking that the insulation is installed according to industry standards and manufacturer guidelines.

- Testing and Commissioning: Conducting thermal imaging or blower door tests to ensure the insulation’s effectiveness.

7. Describe the environmental benefits of using cork insulation and explain how it contributes to sustainable building practices.

Cork insulation provides several environmental benefits:

- Renewable Resource: Cork is harvested from sustainable cork oak forests.

- Low Embodied Energy: Cork production requires less energy than other insulation materials.

- Carbon Sequestration: Cork trees absorb carbon dioxide during their growth.

- Recyclable: Cork can be recycled at the end of its lifespan.

8. How do you stay updated with the latest advancements and best practices in cork insulation installation techniques?

To stay updated, I regularly engage in:

- Industry Conferences and Webinars: Attending industry events and online seminars.

- Research and Development: Reading technical articles and staying informed about new materials and techniques.

- Manufacturer Training: Participating in training programs offered by cork insulation manufacturers.

9. What is your approach to working collaboratively with other trades on a construction site to ensure a successful insulation installation?

My approach includes:

- Communication: Establishing clear lines of communication with other trades.

- Coordination: Scheduling insulation installation to minimize conflicts with other tasks.

- Problem-Solving: Collaborating with other trades to find solutions to unforeseen challenges.

10. How do you handle situations when you encounter unforeseen challenges or defects during cork insulation installation?

When faced with challenges, I take the following steps:

- Assessment: Identifying the nature and extent of the challenge.

- Consultation: Seeking advice from colleagues, manufacturers, or engineers if necessary.

- Solution Implementation: Developing and executing a corrective action plan.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cork Insulation Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cork Insulation Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cork Insulation Installers play a crucial role in the construction industry, specializing in the installation of cork insulation materials. They ensure that buildings meet energy-saving regulations, reducing heat loss and improving indoor comfort.

1. Insulation Installation

Core responsibility involves installing cork insulation in various forms, including sheets, rolls, and boards. Installers must adhere to building codes and manufacturer specifications to ensure proper performance.

- Cut and shape insulation materials to fit specific areas.

- Apply adhesives and sealants to bond insulation to surfaces.

2. Site Preparation

Prior to insulation installation, installers prepare work areas. This includes:

- Inspecting surfaces to identify potential issues.

- Cleaning and prepping surfaces to ensure proper adhesion.

- Installing vapor barriers to protect insulation from moisture.

3. Quality Control

Installers are responsible for maintaining the highest standards of quality. They:

- Inspect installed insulation for proper coverage and adherence.

- Test insulation to verify its performance and effectiveness.

- Provide documentation to demonstrate compliance with specifications.

4. Safety and Compliance

Cork Insulation Installers prioritize safety and compliance by:

- Using proper safety gear and following industry regulations.

- Handling insulation materials safely to avoid potential hazards.

- Keeping work areas organized and free from debris.

Interview Tips

Preparing for an insulation installer interview requires a combination of technical knowledge, practical skills, and professional presentation. Here are some effective tips to help you ace the interview:

1. Research the Company

Demonstrate your interest and commitment by researching the company’s background, values, and recent projects. This knowledge helps you align your skills and experience with the company’s needs.

2. Highlight Your Expertise

Emphasize your proficiency in installing cork insulation materials. Showcase your understanding of different insulation types, installation techniques, and industry standards. Provide specific examples of your successful projects.

3. Practice Your Answers

Prepare for common interview questions by practicing your responses. This includes questions about your technical skills, experience, and safety practices. Anticipate behavioral questions that explore your problem-solving and teamwork abilities.

4. Bring Relevant Documents

Consider bringing a portfolio of your previous work, including photos or documentation of your insulation installations. This tangible evidence can provide the interviewer with a clear representation of your capabilities.

5. Prepare Industry Questions

Impress the interviewer by asking insightful questions about industry trends, new insulation technologies, or the company’s environmental sustainability initiatives. This demonstrates your interest in the field and your desire for professional growth.

6. Dress Professionally

Dress appropriately for the interview, even if it’s not a formal setting. First impressions matter, and a professional appearance conveys respect and seriousness about the opportunity.

7. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic demeanor. Show your passion for insulation work and your eagerness to contribute to the company’s success. Remember to smile, make eye contact, and speak confidently.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cork Insulation Installer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cork Insulation Installer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.