Are you gearing up for an interview for a Corking Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Corking Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

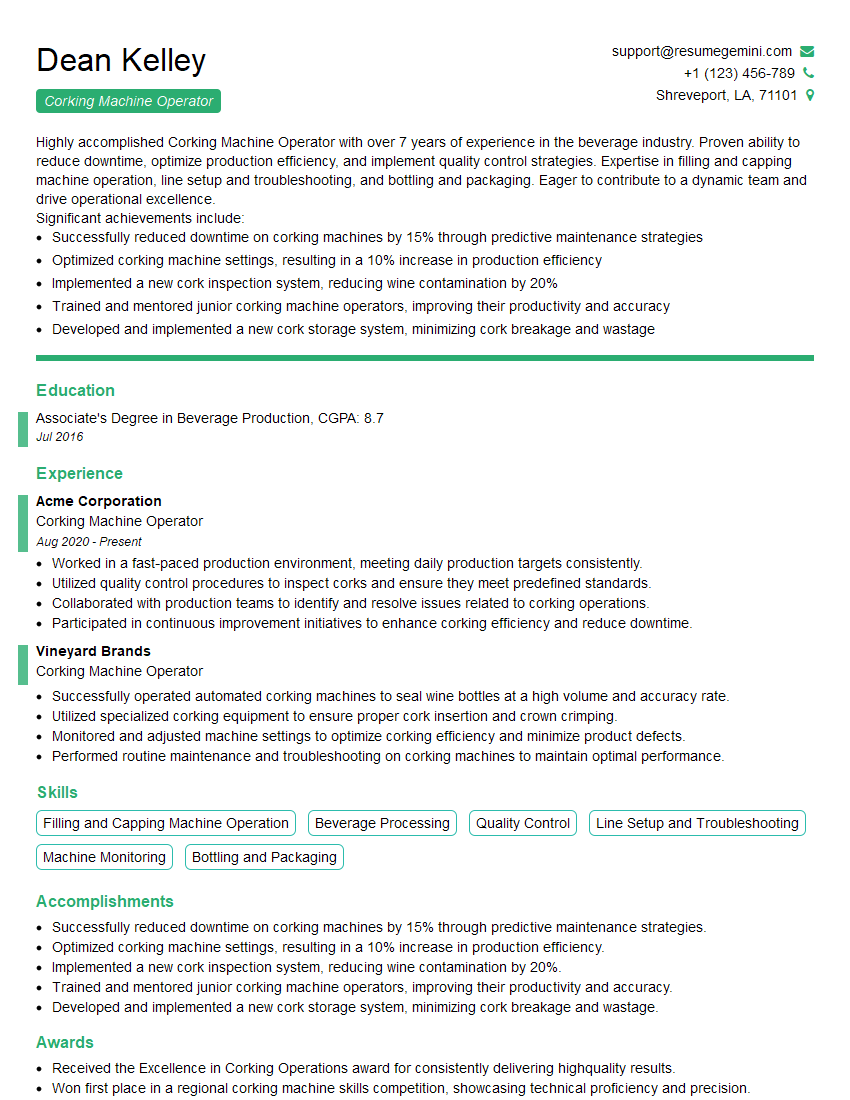

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corking Machine Operator

1. Explain the process of operating a corking machine?

I understand that operating a corking machine involves several steps. Here’s a general overview:

- Load the corks: The corks are typically loaded into a hopper or magazine.

- Prepare the bottles: The bottles are placed in the designated area of the machine.

- Insert the corks: The machine automatically inserts the corks into the bottles.

- Seal the corks: Once the corks are inserted, the machine applies pressure or heat to seal them.

- Eject the bottles: The sealed bottles are ejected from the machine.

2. Describe the different types of corking machines and their applications?

Automatic corking machines

- High-speed operation

- Suitable for large-scale production

Semi-automatic corking machines

- Require manual insertion of corks

- Ideal for smaller production runs

Manual corking machines

- Entirely manual operation

- Suitable for low-volume production or specialty applications

3. What are the critical maintenance tasks for a corking machine?

To ensure optimal performance and longevity, regular maintenance is essential.

- Regular cleaning to remove cork dust and debris

- Lubricating moving parts

- Inspecting and replacing worn or damaged parts

- Calibrating the machine to ensure accurate cork insertion and sealing

4. How do you troubleshoot common problems encountered when operating a corking machine?

Troubleshooting is essential to minimize downtime.

- Clogged hopper: Clear the hopper of any obstructions.

- Damaged corks: Inspect the corks and replace any defective ones.

- Insufficient pressure or heat: Adjust the machine settings accordingly.

- Faulty sensors: Check the sensors and replace them if necessary.

5. What safety precautions should be taken when working with a corking machine?

Safety is paramount.

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands away from moving parts.

- Follow proper lockout/tagout procedures before performing maintenance.

- Ensure the work area is well-ventilated to avoid exposure to cork dust.

6. How do you maintain quality control when operating a corking machine?

- Regularly inspect the corks to ensure they meet specifications.

- Monitor the sealing process to ensure proper adhesion.

- Conduct random checks on sealed bottles to verify their integrity.

- Keep detailed records of production and maintenance activities.

7. What is the importance of proper corking techniques?

Proper corking techniques are crucial for preserving the quality of the bottled product.

- Ensures a tight seal to prevent leakage and oxidation.

- Preserves the flavor and aroma of the product.

- Enhances the overall presentation and appeal of the product.

8. What are the recent advancements in corking technology?

The corking industry is constantly evolving.

- Automated corking machines with advanced sensors and controls.

- New cork materials and sealing techniques to improve product longevity.

- Integration of quality control systems to monitor and ensure consistent production.

9. How do you stay up-to-date with the latest industry best practices for corking operations?

- Attending industry conferences and workshops.

- Reading trade publications and technical articles.

- Consulting with industry experts.

- Participating in online forums and discussion groups.

10. What are your strengths and weaknesses as a Corking Machine Operator?

Highlight relevant skills and experience as a Corking Machine Operator.

Strengths:

- Expertise in operating various types of corking machines.

- Proven ability to maintain high production rates while ensuring quality.

- Strong troubleshooting skills and knowledge of machine maintenance.

Weaknesses:

- Limited experience with specific types of equipment or packaging formats.

- Working in a fast-paced environment can occasionally lead to stress.

- Continuously seeking opportunities to improve skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corking Machine Operators play a crucial role in the manufacturing process of various industries, such as food and beverage, pharmaceutical, and chemical. Their primary responsibility is to operate and maintain corking machines that insert corks into bottles or containers to seal them.

1. Machine Operation and Maintenance

Corking Machine Operators are responsible for setting up, operating, and maintaining corking machines to ensure efficient and accurate corking of containers. This includes:

- Adjusting machine settings to accommodate different bottle or container sizes and cork types

- Monitoring the machine’s performance, detecting any malfunctions or anomalies, and taking corrective actions

- Performing regular maintenance tasks, such as cleaning and lubricating the machine, to ensure optimal functionality

2. Quality Control

Corking Machine Operators must ensure that the corking process meets the required quality standards. This involves:

- Inspecting corks for defects or damage before inserting them into containers

- Ensuring that corks are inserted properly and securely to prevent leakage or contamination

- Adhering to established quality control procedures and maintaining accurate records of corking operations

3. Material Handling

Corking Machine Operators are typically responsible for handling and transporting corks, bottles, or containers throughout the corking process. This includes:

- Loading and unloading corks from designated areas

- Positioning bottles or containers on the corking machine

- Removing corked containers from the machine and placing them in appropriate storage areas

4. Safety Compliance

Corking Machine Operators must prioritize safety in their workplace. This involves:

- Following established safety protocols and wearing appropriate personal protective equipment

- Identifying and mitigating potential hazards associated with machine operation or material handling

- Reporting any safety concerns or accidents promptly to supervisors or designated personnel

Interview Tips

Preparing well for an interview is essential to showcase your skills and increase your chances of success. Here are some tips to help you ace your interview for a Corking Machine Operator position:

1. Research the Company and Position

Familiarize yourself with the company you’re applying to, including their industry, products or services, and company culture. Research the specific Corking Machine Operator position to gain a thorough understanding of its responsibilities and requirements.

2. Highlight Relevant Experience and Skills

Emphasize your experience operating and maintaining corking machines or similar equipment. Quantify your accomplishments to demonstrate your impact and results. Highlight your attention to detail, quality control mindset, and ability to work in a fast-paced environment.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” Practice your answers aloud to build confidence and ensure clarity.

4. Prepare Industry-Specific Questions

Research the industry where the corking machines are used, such as food and beverage, pharmaceutical, or chemical. Understand the specific requirements and challenges associated with corking operations in that industry and prepare questions to demonstrate your knowledge.

5. Ask Thoughtful Questions

Prepare thoughtful questions to ask the interviewer at the end of the interview. This shows your interest and engagement. Ask about the company’s growth plans, the specific challenges faced by Corking Machine Operators, or opportunities for professional development.

6. Professionalism and Enthusiasm

Dress professionally and arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the interview. Show your interest in the position and the company, and convey your eagerness to contribute to their success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Corking Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.