Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Corn Detasseler Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Corn Detasseler Machine Operator so you can tailor your answers to impress potential employers.

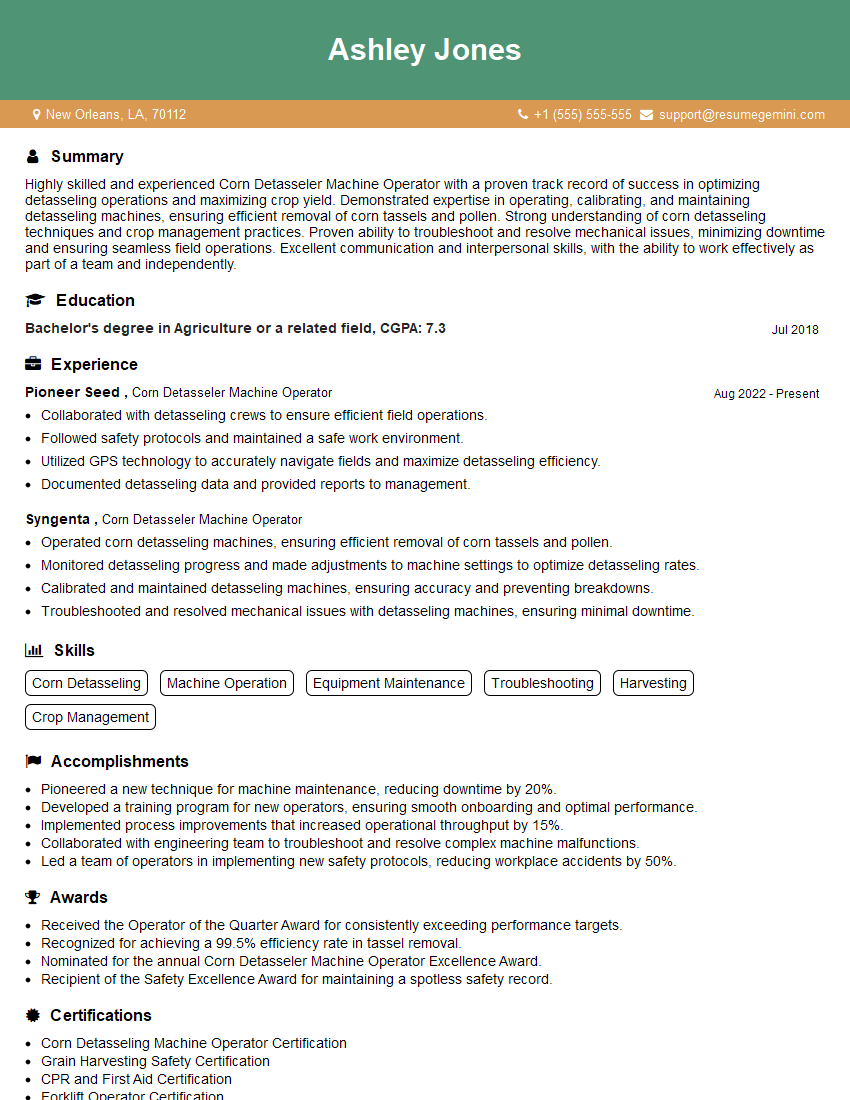

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corn Detasseler Machine Operator

1. Describe the key responsibilities of a Corn Detasseler Machine Operator?

In this role, I am responsible for:

- Operating and maintaining corn detasseling machines to remove tassels from corn plants

- Inspecting and adjusting machines regularly to ensure optimal performance

- Monitoring detasseling progress and making necessary adjustments to maintain the desired detasseling level

- Troubleshooting and resolving machine malfunctions promptly to minimize downtime

- Adhering to safety protocols and regulations while operating machines

2. What are the essential mechanical skills required for a Corn Detasseler Machine Operator?

Understanding of Mechanical Systems

- Knowledge of basic mechanical principles and components

- Ability to troubleshoot and repair simple mechanical issues

Equipment Maintenance

- Proficient in performing preventive maintenance tasks

- Capable of identifying and resolving minor mechanical problems

Hydraulics and Pneumatics

- Familiar with the principles of hydraulic and pneumatic systems

- Able to diagnose and repair basic hydraulic and pneumatic malfunctions

3. How do you ensure the safety and efficiency of the detasseling process?

Safety is paramount, so I adhere to all established safety protocols and regulations, including:

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work environment

- Regularly inspecting machines for any potential hazards

- Promptly reporting any safety concerns or near-misses

- To enhance efficiency, I:

- Optimize machine settings based on field conditions

- Minimize machine downtime through proactive maintenance

- Continuously monitor detasseling results to ensure optimal tassel removal

4. What strategies do you employ to troubleshoot and resolve machine malfunctions?

When troubleshooting malfunctions, I follow a structured approach:

- Identify the problem and gather necessary information

- Review machine manuals and consult with colleagues or supervisors

- Perform a visual inspection and listen for unusual noises

- Conduct diagnostic tests using appropriate tools and equipment

- Isolate the issue to a specific component or subsystem

- Repair or replace faulty parts and reassemble the machine

- Test the machine to verify that the malfunction has been resolved

5. How do you stay updated on the latest advancements and best practices in corn detasseling technology?

To stay abreast of advancements and best practices, I engage in ongoing learning:

- Attend industry conferences and workshops

- Read technical publications and articles

- Consult with manufacturers and experts in the field

- Participate in online forums and discussion groups

- I believe that continuous learning is essential for staying proficient and adapting to new technologies and methods.

6. Can you explain the principles of detasseling and its importance in corn production?

Detasseling is a crucial process in corn production that involves removing the tassels from male corn plants to prevent self-pollination.

- By preventing self-pollination, detasseling promotes cross-pollination, which results in better seed quality

- Improved seed quality leads to higher yields and increased profitability for farmers

- Detasseling also contributes to improved uniformity and disease resistance in corn crops

7. What are the common challenges you face as a Corn Detasseler Machine Operator and how do you overcome them?

One common challenge is varying field conditions, which can affect machine performance.

- To overcome this, I adjust machine settings accordingly and monitor detasseling results closely

- Another challenge is machine downtime due to malfunctions.

- I proactively maintain machines to minimize downtime and promptly troubleshoot and resolve any issues that arise

- Additionally, weather conditions can impact the detasseling process.

- I monitor weather forecasts and adjust my work schedule as necessary to avoid operating machines in adverse conditions

8. Describe your most significant accomplishment as a Corn Detasseler Machine Operator?

My most significant accomplishment was successfully detasseling a large field of corn with minimal downtime and achieving an optimal tassel removal rate.

- I meticulously planned the operation, considering field conditions and machine capabilities

- I ensured that the machine was in excellent condition through thorough maintenance

- Throughout the operation, I monitored the detasseling process closely and made necessary adjustments to maintain the desired removal rate

- As a result, I completed the task efficiently and effectively, contributing to a successful corn harvest

9. What motivates you to excel as a Corn Detasseler Machine Operator?

I am driven by the satisfaction of contributing to the agricultural industry and ensuring the production of high-quality corn.

- I take pride in my ability to operate and maintain machines efficiently and effectively

- The challenges of varying field conditions and ensuring optimal detasseling results motivate me to continuously improve my skills

- Moreover, I enjoy working in a team environment and collaborating with others to achieve common goals

10. How do you handle working in remote or isolated areas?

Working in remote areas requires self-sufficiency and adaptability.

- I ensure that I have all the necessary tools and equipment before heading to the field

- I am comfortable working independently and making decisions in the absence of immediate supervision

- In case of any emergencies or unexpected challenges, I have established communication protocols to seek assistance promptly

- I am also mindful of my surroundings and take necessary precautions to maintain safety while working in remote locations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corn Detasseler Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corn Detasseler Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corn Detasseler Machine Operators play a crucial role in the agricultural industry by assisting in the vital process of detasseling corn plants. Detasseling involves removing the tassel from the top of the corn plant to prevent self-pollination and promote cross-pollination, which results in higher yields and improved seed quality.

1. Machine Operation

Effectively operate and maintain detasseling machines, ensuring they are in optimal working condition.

- Monitor machine performance, identifying and troubleshooting any issues promptly.

- Adjust machine settings to optimize detasseling efficiency and minimize damage to plants.

2. Detasseling Process

Skilfully detassel corn plants using the machine, ensuring accurate and thorough removal of tassels.

- Navigate the machine through cornfields, maintaining a steady pace and proper spacing.

- Identify and detassel corn plants at the right stage of development, ensuring maximum seed production.

3. Field Maintenance

Maintain a clean and safe work environment in the cornfields.

- Remove detasseled tassels and other debris from fields to prevent disease and pests.

- Inspect corn plants for signs of pests or diseases and report any findings promptly.

4. Equipment Maintenance

Perform regular maintenance and repairs on detasseling machines and other equipment.

- Inspect and lubricate equipment as per manufacturer’s recommendations.

- Identify and repair minor mechanical issues to ensure smooth operation of equipment.

Interview Tips

Preparing for a Corn Detasseler Machine Operator interview requires a combination of technical knowledge and enthusiasm for agriculture. Here are some tips to help you ace the interview:

1. Technical Proficiency

Thoroughly review the job description and familiarize yourself with the key responsibilities of a Corn Detasseler Machine Operator.

- Research different detasseling machines and their operation principles.

- Gain an understanding of the detasseling process and the impact it has on corn production.

2. Agricultural Knowledge

Demonstrate your knowledge of corn cultivation and the importance of detasseling in the process.

- Familiarize yourself with different corn varieties and their growth stages.

- Understand the role of cross-pollination and its benefits in corn production.

3. Communication Skills

Convey your ability to communicate effectively with supervisors, co-workers, and farmers.

- Practice active listening and demonstrate your understanding of instructions.

- Prepare examples of how you have successfully resolved issues or collaborated with others in a work setting.

4. Safety Awareness

Emphasize your commitment to safety in the workplace.

- Discuss your experience in following safety protocols and using personal protective equipment (PPE).

- Explain how you would prioritize safety in the context of operating detasseling machines.

Next Step:

Now that you’re armed with the knowledge of Corn Detasseler Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Corn Detasseler Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini