Are you gearing up for a career in Corn Husker Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Corn Husker Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

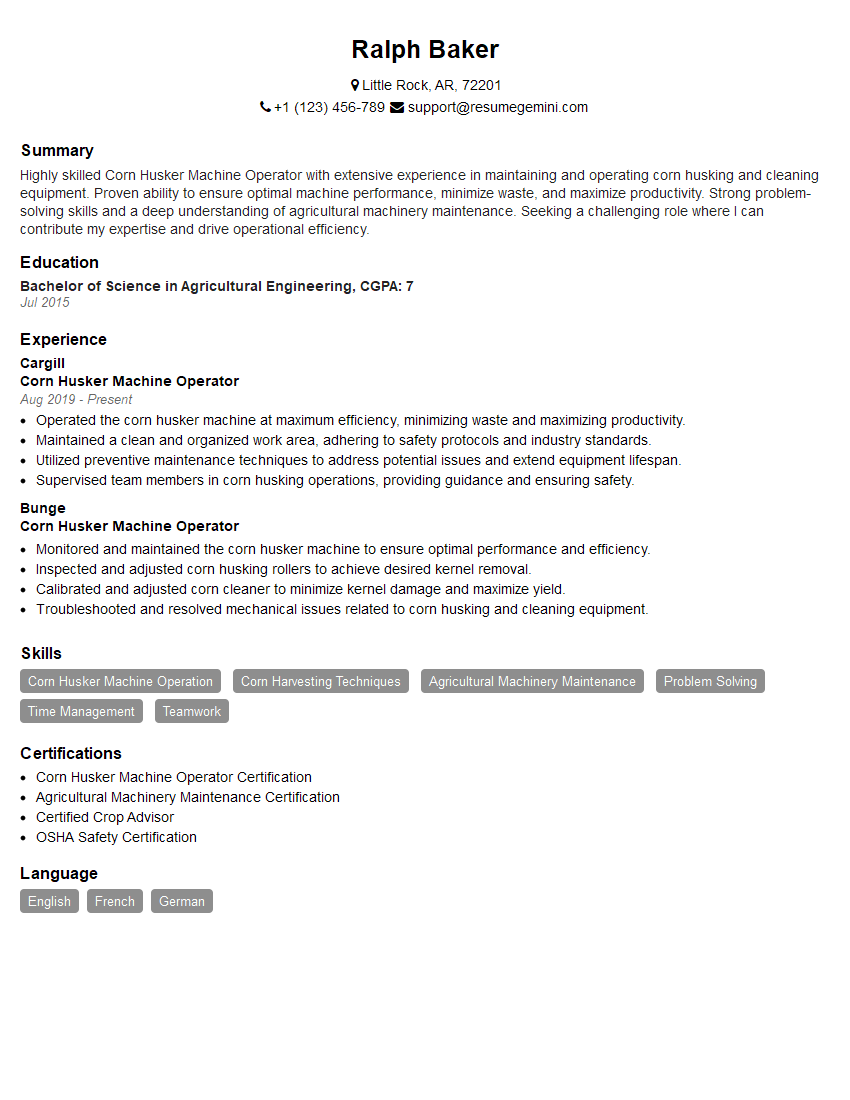

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corn Husker Machine Operator

1. Describe the process of operating a corn husker machine?

The process of operating a corn husker machine involves several steps to effectively remove the husks from corn cobs:

- Input Preparation: Ensure the corn cobs are free of dirt and debris before feeding them into the machine.

- Husking Mechanism: Feed the corn cobs into the husking rollers or blades, which separate the husks from the kernels.

- Husk Removal: The loosened husks are then discharged through designated outlets or conveyors.

- Output Monitoring: Monitor the quality of the husked corn and make adjustments to the machine’s settings as needed.

- Maintenance: Regularly inspect and maintain the machine, including cleaning and lubricating components.

2. Explain the importance of maintaining and calibrating the corn husker machine?

Benefits of Maintenance:

- Extended Machine Life: Regular maintenance prevents premature wear and tear, extending the lifespan of the machine.

- Optimal Performance: Maintained machines operate more efficiently, resulting in higher productivity and fewer breakdowns.

- Reduced Downtime: Proactive maintenance identifies potential issues early on, minimizing unplanned downtime.

- Improved Safety: A properly maintained machine minimizes the risk of accidents and ensures a safe working environment.

Importance of Calibration:

- Accurate Husking: Calibration ensures the machine removes husks effectively without damaging the kernels.

- Consistent Output: Calibrated machines produce uniform husked corn, meeting the required quality standards.

- Optimized Throughput: Proper calibration maximizes the husking efficiency, increasing the overall productivity.

3. Describe the different types of corn husker machines and their applications?

- In-Field Huskers: Mounted on tractors or combines, these machines husk corn directly in the field during harvesting.

- Stationary Huskers: Used in processing facilities, these machines husk large volumes of corn cobs in a stationary setting.

- Wet Huskers: Designed to handle wet or high-moisture corn, these machines use water to loosen the husks before mechanical separation.

- Dry Huskers: Suitable for dry corn, these machines employ friction and mechanical force to remove the husks.

- Specialty Huskers: Designed for specific corn varieties or applications, such as sweet corn or seed corn.

4. What factors influence the efficiency of a corn husker machine?

- Corn Variety: Different corn varieties have varying husk characteristics, affecting the machine’s efficiency.

- Corn Condition: Moisture content, maturity, and damage can impact the husking process.

- Machine Settings: Proper calibration and adjustments to the rollers or blades are crucial for optimal performance.

- Operator Skill: Experienced operators can optimize machine settings and handle variations in corn conditions.

- Maintenance and Upkeep: Regular maintenance and timely repairs ensure the machine operates at peak efficiency.

5. How do you troubleshoot common issues with corn husker machines?

- Clogged Husk Removal: Check for blockages in the outlet or conveyor and clear any debris.

- Inefficient Husking: Inspect the rollers or blades for wear or damage and adjust or replace as needed.

- Excessive Kernel Damage: Verify the machine settings and adjust the roller gap or blade sharpness to minimize kernel damage.

- Machine Overheating: Check for lubrication issues or excessive load on the machine, and address the underlying cause.

- Electrical Faults: Contact a qualified electrician to diagnose and repair any electrical problems.

6. Describe the safety protocols and precautions for operating a corn husker machine?

- Proper Training: All operators must receive thorough training on the machine’s operation and safety features.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves, safety glasses, and hearing protection.

- Guarding and Lockout/Tagout: Ensure all guards and safety devices are in place and functioning before operating the machine.

- Clear Work Area: Keep the work area free of debris and tripping hazards.

- Emergency Stop Procedures: Familiarize yourself with the emergency stop buttons and know the evacuation procedures.

7. Explain the principles of preventive maintenance for corn husker machines?

- Regular Inspections: Conduct scheduled inspections to identify potential issues early on.

- Lubrication and Greasing: Lubricate moving parts regularly to minimize wear and friction.

- Component Replacement: Replace worn or damaged components promptly to prevent further damage.

- Cleaning and Debris Removal: Clean the machine thoroughly and remove any accumulated debris to prevent blockages.

- Record Keeping: Maintain detailed maintenance records to track inspections, repairs, and replacements.

8. How do you optimize the productivity of a corn husker machine?

- Proper Calibration and Adjustments: Ensure the machine is calibrated correctly and adjusted to suit the corn variety and conditions.

- Unload Management: Minimize downtime by ensuring efficient unloading of husked corn.

- Operator Training: Provide operators with comprehensive training to maximize their efficiency and minimize errors.

- Preventative Maintenance: Regular maintenance and timely repairs prolong the machine’s lifespan and reduce breakdowns.

- Data Analysis: Monitor machine performance data to identify areas for improvement and optimize overall productivity.

9. Describe the sustainability practices involved in corn husking operations?

- Energy Efficiency: Utilizing energy-efficient machines and optimizing machine settings.

- Water Conservation: Using water-saving husking methods or recycling water in wet husking systems.

- Waste Reduction: Properly disposing of husks and other waste products.

- Environmental Regulations: Complying with environmental regulations and best practices.

- Sustainable Corn Production: Supporting sustainable corn farming practices to minimize environmental impact.

10. How do you stay updated with the latest advancements in corn husker machine technology?

- Industry Events and Conferences: Attending industry events to learn about new technologies and innovations.

- Trade Publications and Journals: Reading specialized publications to stay informed about industry trends.

- Online Research: Utilizing online resources and manufacturer websites to explore new products and features.

- Direct Contact with Manufacturers: Contacting equipment manufacturers for information on their latest offerings.

- Networking with Colleagues: Connecting with other industry professionals to exchange knowledge and insights.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corn Husker Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corn Husker Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Corn Husker Machine Operator Responsibilities

Corn Husker Machine Operators play a crucial role in the agricultural industry by harvesting corn efficiently. Their responsibilities encompass operating, maintaining, and troubleshooting corn husking machines, ensuring optimal corn removal from the stalks while minimizing grain loss.

1. Equipment Operation

- Operate husking machines according to manufacturers’ specifications

- Adjust machine settings to optimize corn removal and minimize grain loss

- Monitor machine performance and identify potential issues

2. Equipment Maintenance

- Perform routine maintenance on corn huskers, including lubrication and cleaning

- Inspect and replace worn or damaged components

- Collaborate with maintenance personnel to resolve complex issues

3. Troubleshooting

- Identify and diagnose machine malfunctions

- Take corrective actions to resolve issues promptly

- Maintain detailed records of repairs and maintenance activities

4. Safety and Compliance

- Follow established safety protocols and regulations

- Wear appropriate protective gear

- Comply with environmental regulations related to corn harvesting

Interview Preparation Tips for Corn Husker Machine Operator

1. Research the Company and Industry

- Familiarize yourself with the company’s history, mission, and operations

- Research the agricultural industry, focusing on corn harvesting practices

2. Practice Your Answers

- Prepare for common interview questions related to your skills and experience

- Rehearse your answers to highlight your strengths and qualifications

3. Demonstrate Your Knowledge

- Discuss your understanding of corn husking machines, their operation, and maintenance

- Share examples of how you have solved problems or improved efficiency in previous roles

4. Emphasize Safety

- Stress your commitment to safety and compliance

- Describe your experience with safety protocols and how you ensure a safe work environment

5. Ask Relevant Questions

- Inquire about the company’s harvesting methods and sustainability practices

- Ask about opportunities for professional development and advancement

Next Step:

Now that you’re armed with the knowledge of Corn Husker Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Corn Husker Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini