Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Corn Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Corn Press Operator so you can tailor your answers to impress potential employers.

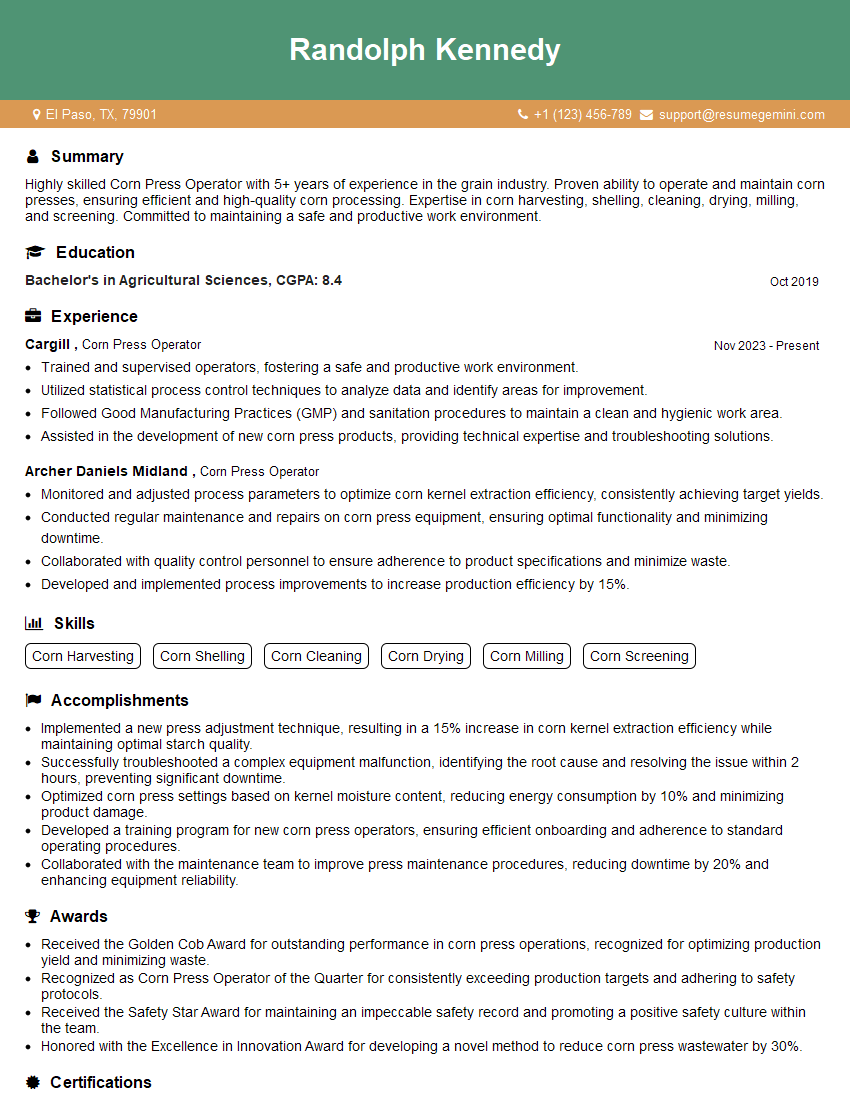

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corn Press Operator

1. What are the key responsibilities of a Corn Press Operator?

As a Corn Press Operator, I would be responsible for:

- Operating and maintaining corn pressing equipment to extract oil and produce corn germ and fiber.

- Ensuring the proper functioning of the press and monitoring pressure, temperature, and other parameters.

- Calibrating and adjusting equipment to optimize performance and minimize downtime.

- Monitoring product quality using appropriate testing methods and making adjustments to the process as needed.

- Performing routine maintenance and cleaning of equipment to ensure hygiene and safety.

- Adhering to safety protocols, following established procedures, and reporting any issues or potential hazards.

2. Explain the process of corn pressing.

Corn Preparation

- Cleaning and conditioning corn kernels to remove impurities and optimize pressability.

- Adjusting moisture content to achieve desired oil yield and quality.

Pressing

- Feeding prepared corn kernels into the press and applying controlled pressure to extract oil.

- Separating extracted oil from corn solids (germ and fiber).

Post-Processing

- Further processing of corn germ to produce corn oil and protein products.

- Drying and packaging corn fiber for use in animal feed or industrial applications.

3. What are the main factors that affect the efficiency of corn pressing?

The efficiency of corn pressing can be influenced by factors such as:

- Kernel moisture content: Optimal moisture content ensures maximum oil yield and quality.

- Pressing temperature: Controlled temperature helps maintain oil quality and prevents degradation.

- Pressing pressure: Proper pressure application optimizes oil extraction while minimizing energy consumption.

- Equipment condition: Regular maintenance and calibration ensure optimal press performance and efficiency.

- Corn variety: Different corn varieties have varying oil content and pressing characteristics.

4. How do you handle and resolve common problems encountered during corn pressing?

Common problems during corn pressing and their potential solutions include:

- Low oil yield: Adjust pressing parameters (pressure, temperature, moisture content), check equipment calibration, and inspect for blockages.

- Poor oil quality: Optimize pressing conditions, check for contamination, and ensure proper storage and handling of oil.

- Equipment malfunctions: Follow troubleshooting procedures, conduct regular maintenance, and notify maintenance personnel promptly.

- Safety hazards: Adhere to safety protocols, wear appropriate protective gear, and report any potential risks or incidents.

5. Describe the safety precautions you observe while operating corn pressing equipment.

To ensure safety while operating corn pressing equipment, I would:

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and earplugs.

- Follow established lockout/tagout procedures before performing maintenance or repairs.

- Be aware of potential hazards such as moving machinery, hot surfaces, and slippery floors.

- Keep the work area clean and organized to prevent tripping or slipping.

- Report any unsafe conditions or equipment malfunctions to supervisors immediately.

6. What are the quality control procedures involved in corn pressing?

Quality control measures in corn pressing ensure product consistency and meet customer specifications:

- Raw material inspection: Inspecting corn kernels for quality, moisture content, and foreign objects.

- Process monitoring: Regularly measuring and recording pressing parameters (pressure, temperature, moisture).

- Oil analysis: Conducting laboratory tests to determine oil quality, acidity, and fatty acid profile.

- Corn germ and fiber inspection: Assessing quality and characteristics of byproducts.

- Documentation: Maintaining detailed records of all quality control procedures and results.

7. How do you optimize corn press performance to maximize oil yield and quality?

To optimize corn press performance, I would:

- Calibrate and maintain equipment: Ensure proper functionality and accuracy of all press components.

- Monitor and adjust pressing parameters: Optimize pressure, temperature, and moisture content based on corn variety and desired product quality.

- Control corn preparation: Properly clean, condition, and adjust moisture content of corn kernels.

- Implement quality control measures: Regularly monitor process parameters and conduct product testing to identify and address any deviations.

- Conduct regular maintenance: Perform scheduled maintenance and cleaning to prevent breakdowns and ensure optimal equipment performance.

8. What measures do you take to minimize waste and maximize resource efficiency in corn pressing?

To minimize waste and promote resource efficiency in corn pressing, I would:

- Optimize pressing conditions: Adjust parameters to minimize energy consumption while maintaining product quality.

- Repurpose byproducts: Utilize corn germ and fiber for animal feed or industrial applications, reducing waste.

- Regularly clean and maintain equipment: Preventative maintenance helps minimize energy loss and ensures efficient operation.

- Implement waste reduction programs: Train staff on waste reduction practices and establish waste monitoring systems.

- Collaborate with other departments: Work with procurement and production teams to identify opportunities for material reuse or recycling.

9. How do you stay updated on industry best practices and technological advancements in corn pressing?

To stay abreast of industry best practices and technological advancements in corn pressing, I would:

- Attend industry conferences and workshops: Network with experts and learn about latest trends.

- Read industry publications and research papers: Stay informed about new technologies and research findings.

- Seek professional development opportunities: Participate in training programs and certifications to enhance my knowledge and skills.

- Collaborate with colleagues and vendors: Share knowledge and learn from others in the field.

- Monitor industry news and online resources: Stay updated on industry developments and emerging technologies.

10. Why are you interested in this Corn Press Operator position, and how do you see yourself contributing to our team?

I am eager to join your team as a Corn Press Operator for the following reasons:

- My technical skills and experience in corn pressing align well with the requirements of this role.

- I am passionate about optimizing processes and ensuring product quality, which is crucial in this industry.

- I am a proactive and results-oriented individual with a strong work ethic and attention to detail.

- I believe that my expertise and commitment to safety and efficiency would make me a valuable asset to your team.

- I am eager to learn and grow within this industry, and I am confident that I can make a significant contribution to your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corn Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corn Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corn Press Operators are responsible for operating and maintaining corn presses to extract oil from corn kernels. They play a vital role in the food production industry, ensuring the efficient and safe operation of corn pressing equipment.

1. Equipment Operation

Operate corn presses to extract oil from corn kernels

- Monitor press settings and adjust as needed to optimize oil extraction

- Clean and maintain presses to ensure efficient operation

2. Quality Control

Inspect corn kernels and ensure they meet quality standards

- Test oil samples to ensure it meets specifications

- Implement and follow quality control procedures

3. Safety and Maintenance

Adhere to all safety protocols and regulations

- Maintain a clean and organized work area

- Perform regular maintenance and repairs on presses

4. Supervision and Training

Supervise and train new employees on operating procedures

- Maintain accurate records of operations and maintenance

- Troubleshoot and resolve production issues

Interview Tips

Preparing thoroughly for a Corn Press Operator interview is crucial for making a positive impression and increasing your chances of landing the job. Here are some effective interview preparation tips to help you ace the interview:

1. Research the company and industry

Familiarize yourself with the company’s history, products, and industry trends.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed.

2. Practice your answers to common questions

Anticipate questions about your experience, skills, and qualifications.

- Prepare concise and well-structured answers that highlight your relevant abilities.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

3. Prepare questions to ask the interviewer

Asking thoughtful questions demonstrates your interest and engagement.

- Inquire about the company’s growth plans, industry challenges, or opportunities for professional development.

- Show that you’re eager to contribute and learn more about the role.

4. Dress professionally and arrive on time

First impressions matter.

- Wear clean and appropriate business attire.

- Arrive for the interview punctually to show respect for the interviewer’s time.

5. Be confident and enthusiastic

A positive attitude can make a significant impact.

- Maintain eye contact, smile, and speak clearly.

- Showcase your enthusiasm for the role and the industry.

6. Follow up after the interview

Send a thank-you note to the interviewer within 24 hours.

- Express your appreciation for their time and consideration.

- Reiterate your interest in the position and why you believe you’re a suitable candidate.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Corn Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.