Feeling lost in a sea of interview questions? Landed that dream interview for Corncob Pipe Manufacturing Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Corncob Pipe Manufacturing Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

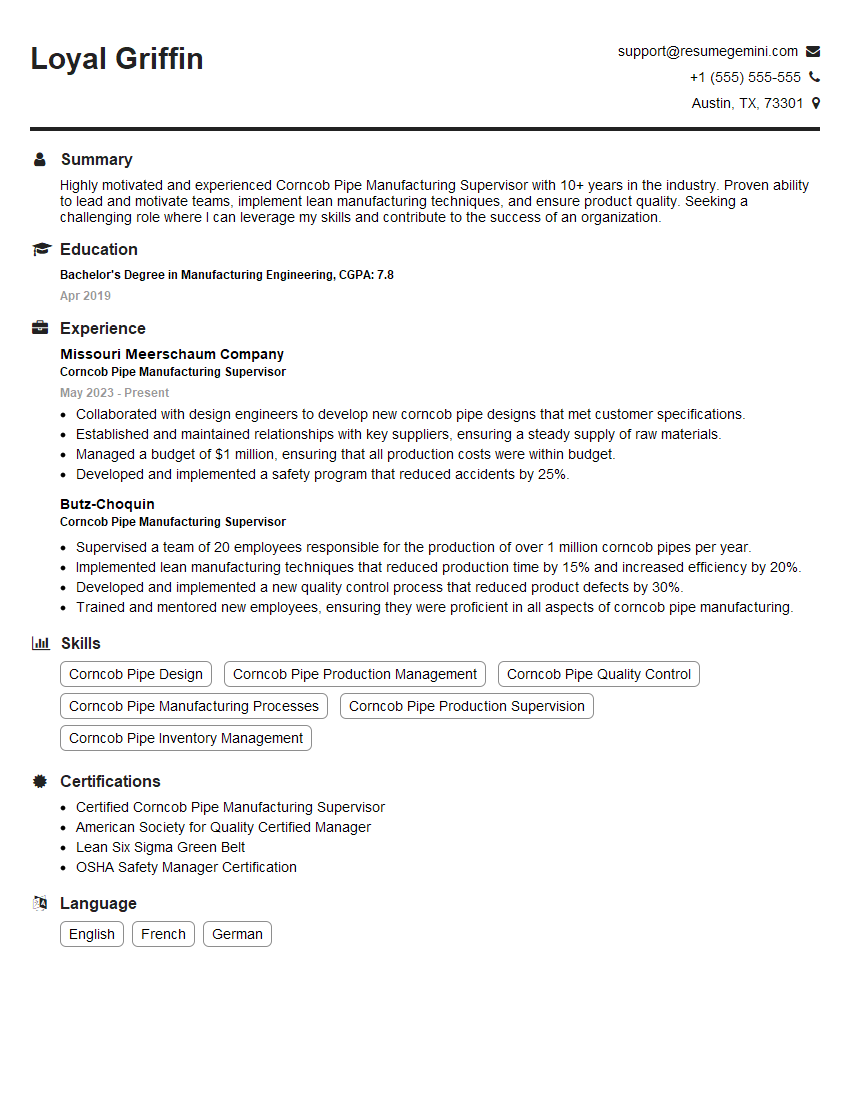

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corncob Pipe Manufacturing Supervisor

1. Explain the process of selecting and preparing corncobs for pipe making?

- Selecting corncobs with the desired size, shape, and density.

- Cleaning and removing impurities from the corncobs.

- Aging the corncobs to improve their smoking quality.

- Cutting and shaping the corncobs into the desired pipe form.

2. Describe the different types of corncob pipes and their characteristics?

Types of Corncob Pipes

- Missouri Meerschaum Cobs: Known for their natural color and lightweight.

- Country Gentleman Cobs: Feature a longer stem and a larger bowl.

- Legend Cobs: Boast a smooth, polished finish and intricate designs.

- Vintage Cobs: Sought after for their unique, aged appearance.

Characteristics of Corncob Pipes

- Natural and absorbent, providing a cool and dry smoke.

- Durable and resistant to heat and moisture.

- Lightweight and easy to handle.

- Economical and offer a great value for the price.

3. What are the key factors that affect the quality of corncob pipes?

- Quality of the corncobs used (size, shape, density).

- Proper aging and curing of the corncobs.

- Precision in cutting and shaping the pipes.

- Quality of the materials used for stems and mouthpieces.

- Consistency in manufacturing processes.

4. How do you ensure that the pipes meet the required quality standards?

- Implementing a rigorous quality control system.

- Inspecting corncobs thoroughly before and after aging.

- Monitoring manufacturing processes closely and making adjustments as necessary.

- Conducting regular testing to ensure pipes meet specifications.

- Receiving feedback from customers and using it to improve quality.

5. Describe the production process of corncob pipes from start to finish?

- Selecting and preparing corncobs.

- Cutting and shaping the cobs.

- Drilling the airway and bowl.

- Fitting the stem and mouthpiece.

- Aging and finishing the pipes.

- Packaging and shipping the pipes.

6. What are the common challenges faced in corncob pipe manufacturing and how do you overcome them?

- Inconsistent corncob quality: Work with reliable suppliers and implement strict quality control measures.

- Production delays: Plan production schedules carefully, maintain equipment regularly, and have contingency plans.

- Quality defects: Train staff properly, monitor processes closely, and use quality control tools.

- Market fluctuations: Stay informed about industry trends, diversify product offerings, and explore new markets.

- Competition: Offer unique products, focus on customer service, and build a strong brand reputation.

7. How do you stay up-to-date with the latest advancements and trends in corncob pipe making?

- Attending industry conferences and exhibitions.

- Reading trade publications and online resources.

- Networking with other manufacturers and experts.

- Conducting research and development to explore new techniques.

- Listening to customer feedback and adapting products accordingly.

8. What are the safety precautions and regulations that need to be followed in corncob pipe manufacturing?

- Using sharp tools and equipment safely.

- Proper handling and storage of chemicals.

- Maintaining a clean and organized work environment.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols and procedures.

9. How do you motivate and lead your team to achieve production goals while maintaining quality standards?

- Setting clear goals and expectations.

- Providing regular feedback and recognition.

- Creating a positive and supportive work environment.

- Delegating responsibilities and empowering team members.

- Encouraging collaboration and knowledge sharing.

10. What are your strengths and weaknesses as a Corncob Pipe Manufacturing Supervisor?

Strengths

- In-depth knowledge of corncob pipe manufacturing processes.

- Strong leadership and team management skills.

- Proven ability to maintain high quality standards.

- Experience in implementing and improving production systems.

- Excellent communication and interpersonal skills.

Weaknesses

- Limited experience in managing large-scale manufacturing operations.

- Can be detail-oriented at times, which may slow down decision-making.

- Need to improve time management skills to handle multiple responsibilities effectively.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corncob Pipe Manufacturing Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corncob Pipe Manufacturing Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Corncob Pipe Manufacturing Supervisor, you will be responsible for overseeing and managing all aspects of the corncob pipe manufacturing process, including:

1. Production Planning and Scheduling

Determining production schedules, ensuring timely delivery of products, and optimizing production efficiency.

- Forecasting production needs based on market demand and customer orders.

- Scheduling production runs, allocating resources, and managing inventory levels.

2. Quality Control and Assurance

Maintaining high product quality standards, ensuring adherence to specifications, and resolving any quality issues.

- Establishing and implementing quality control procedures.

- Inspecting raw materials, work-in-progress, and finished products.

- Analyzing quality data and identifying areas for improvement.

3. Team Management and Supervision

Leading and motivating a team of production workers, providing training and support, and ensuring a safe and productive work environment.

- Recruiting, hiring, and training new employees.

- Delegating tasks, assigning responsibilities, and providing feedback.

- Maintaining a positive and collaborative work culture.

4. Equipment Maintenance and Troubleshooting

Ensuring that all equipment is functioning properly, conducting routine maintenance, and resolving any technical issues that may arise.

- Maintaining a preventative maintenance schedule.

- Troubleshooting equipment failures and implementing corrective actions.

- Coordinating with maintenance technicians for repairs and upgrades.

Interview Tips

To ace your interview for a Corncob Pipe Manufacturing Supervisor position, follow these preparation tips and hacks:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s history, products, and market position.

- Visit the company website and study their latest news and press releases.

- Research the corncob pipe manufacturing industry, including trends and challenges.

2. Highlight Your Experience and Skills

Emphasize your experience in production planning, quality control, team management, and equipment maintenance.

- Use the STAR method (Situation, Task, Action, Result) to describe your accomplishments.

- Quantify your results whenever possible, using specific metrics.

3. Show Your Passion for Corncob Pipes

Convey your enthusiasm for the industry and your interest in the specific products manufactured by the company.

- Share your personal experiences with corncob pipes.

- Articulate your understanding of the unique qualities and craftsmanship involved.

4. Be Prepared to Answer Technical Questions

Anticipate questions about corncob pipe manufacturing processes, equipment, and quality control techniques.

- Review basic principles of pipe making, including corncob selection and shaping.

- Familiarize yourself with common equipment used in pipe manufacturing.

5. Show Your Leadership Qualities

Demonstrate your ability to lead and motivate a team, foster collaboration, and resolve conflicts.

- Describe how you have inspired and empowered your team members.

- Share examples of how you have effectively managed conflict and built a positive work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Corncob Pipe Manufacturing Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Corncob Pipe Manufacturing Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.