Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Corner Trimmer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Corner Trimmer Operator so you can tailor your answers to impress potential employers.

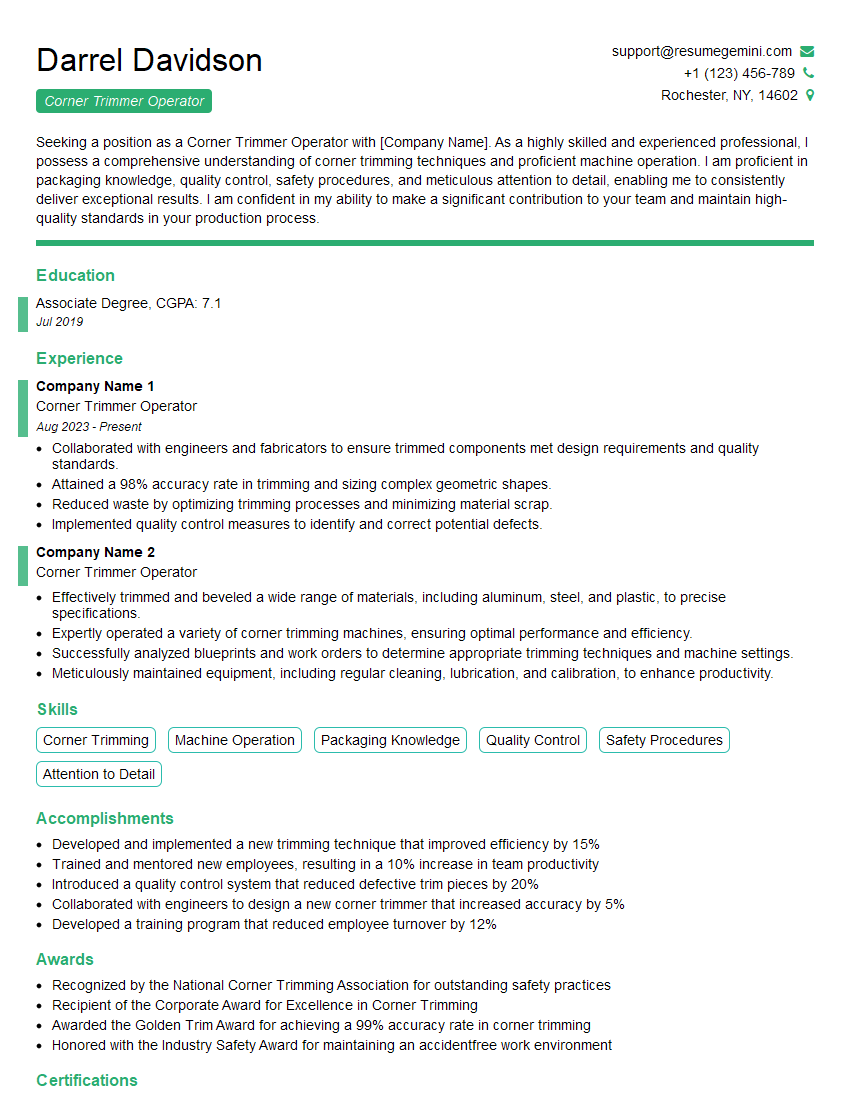

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corner Trimmer Operator

1. Describe the basic principles of corner trimming and its importance in manufacturing?

Corner trimming is a crucial process in manufacturing that involves the removal of excess material from the corners of a workpiece to achieve specific dimensions, tolerances, and aesthetic finishes. This process is essential to ensure the precision, functionality, and quality of the final product.

2. How do you calibrate and maintain a corner trimming machine?

Calibrating and maintaining a corner trimming machine are vital to ensure accurate and consistent results. Calibration involves setting the machine’s parameters, such as cutting depth, feed rate, and spindle speed, according to the specific material and desired trim dimensions. Regular maintenance includes cleaning, lubrication, and replacement of worn parts to maintain optimal performance.

3. What are the different types of corner trimming tools, and when should each type be used?

There are various types of corner trimming tools, each designed for specific materials and applications. Flat end mills are commonly used for general-purpose corner trimming, while ball end mills provide a smooth and contoured finish. Dovetail end mills are suitable for creating grooves or pockets, and radius end mills are ideal for generating rounded corners. The choice of tool depends on the desired shape, material, and finishing requirements.

4. What is the purpose of using coolant or flood coolant in corner trimming operations?

Coolant or flood coolant plays a critical role in corner trimming operations. It serves multiple purposes, including reducing friction and heat generation during the cutting process, which helps to prevent tool wear and workpiece damage. Coolant also flushes away chips and debris, improving surface finish and extending tool life.

5. What are the common problems that can occur during corner trimming and how do you troubleshoot them?

Various problems can arise during corner trimming, affecting the quality and precision of the cut. These include excessive vibration, burrs or sharp edges, uneven surface finish, and tool breakage. Troubleshooting involves identifying the root cause of the problem and implementing corrective actions, such as adjusting cutting parameters, optimizing toolpath strategy, and ensuring proper tool selection and maintenance.

6. How do you ensure the accuracy and consistency of corner trimming operations?

Ensuring accuracy and consistency in corner trimming requires careful attention to several factors. These include precise machine setup, accurate tool selection and calibration, optimizing cutting parameters, implementing efficient toolpath strategies, and implementing quality control measures. Regular monitoring and inspection of the trimmed workpieces help identify any deviations from specifications and enable timely adjustments to maintain desired quality standards.

7. Describe your experience in programming and optimizing toolpaths for corner trimming operations?

Programming and optimizing toolpaths are crucial for efficient and effective corner trimming. I have experience using CAM software to generate toolpaths that minimize tool travel time, reduce machining time, and ensure smooth and accurate cutting. I consider factors such as material properties, tool geometry, and machining conditions to optimize toolpaths for optimal performance.

8. How do you handle complex corner trimming operations involving multiple passes or profiles?

Complex corner trimming operations require careful planning and execution. I approach such tasks by breaking them down into smaller steps, defining multiple passes or profiles, and optimizing toolpath strategies accordingly. I utilize CAM software features like toolpath linking and synchronization to ensure smooth transitions between passes and maintain accuracy throughout the entire trimming process.

9. How do you manage quality control and inspection processes for corner trimming operations?

Quality control and inspection are essential to ensure the accuracy and consistency of corner trimming operations. I follow established quality control procedures, including regular workpiece inspection at various stages of the process. I use precision measuring instruments and gauges to verify dimensions, surface finish, and other critical parameters. Any deviations from specifications are promptly identified and addressed to maintain product quality.

10. How do you stay updated with the latest advancements and best practices in corner trimming technology?

Staying abreast of the latest advancements and best practices in corner trimming technology is crucial for continuous improvement. I attend industry conferences, read technical literature, and actively engage in online forums and discussions. This proactive approach allows me to incorporate innovative techniques, optimize processes, and enhance the overall efficiency and quality of my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corner Trimmer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corner Trimmer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Corner Trimmer Operator is responsible for operating and maintaining a corner trimming machine that trims excess material from the corners of paper, board, or other materials. The operator ensures that the machine is functioning properly and that the materials are trimmed to the correct dimensions. Key responsibilities include:

1. Machine Operation

Operate and maintain a corner trimming machine as per company policies.

- Set up and adjust the machine according to job specifications.

- Load and feed materials into the machine.

- Monitor the trimming process and make adjustments as needed.

- Unload finished materials from the machine.

2. Material Handling

Handle materials safely and efficiently.

- Unload materials from delivery trucks.

- Inspect materials for damage or defects.

- Transport materials to the trimming machine.

- Dispose of waste materials properly.

3. Quality Control

Inspect trimmed materials to ensure they meet quality standards.

- Check dimensions and squareness of trimmed materials.

- Look for any scratches, tears, or other defects.

- Reject materials that do not meet specifications.

- Report any quality issues to supervisors.

4. Maintenance

Perform basic maintenance on the corner trimming machine.

- Clean and lubricate the machine regularly.

- Inspect the machine for wear and tear.

- Report any maintenance issues to supervisors.

- Assist with major repairs and overhauls as needed.

Interview Tips

Preparing thoroughly for a job interview increases your chances of making a positive impression and landing the job. Here are some tips:

1. Research the Company and Position

Research the company’s website, LinkedIn page, and industry news to learn about their culture, values, and recent developments. This will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Learn about the company’s products or services.

- Read about the company’s mission, vision, and values.

- Check out the company’s social media pages.

2. Practice Answering Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?” Practice answering these questions out loud to become more comfortable and confident.

- Use the STAR method to answer behavioral questions.

- Quantify your accomplishments whenever possible.

- Tailor your answers to the specific job you’re applying for.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows the interviewer that you respect their time and that you’re serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive at the interview location 5-10 minutes early.

- Bring a portfolio or resume to showcase your skills and experience.

4. Be Enthusiastic and Ask Questions

Show the interviewer that you’re enthusiastic about the position by asking thoughtful questions. This also demonstrates your interest and engagement in the conversation. Ask questions about the company, the position, and the team you would be working with.

- Prepare a list of questions to ask the interviewer.

- Be specific and ask questions that show you’re genuinely interested in the position.

- Listen attentively to the interviewer’s answers and ask follow-up questions to clarify or expand on their responses.

Next Step:

Now that you’re armed with the knowledge of Corner Trimmer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Corner Trimmer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini